One-dimensional X-ray multi-layer film waveguide structure and preparation method thereof

A technology of waveguide structure and multilayer film, which is applied in the field of one-dimensional X-ray multilayer film waveguide structure and its preparation, can solve the problems of X-ray loss and low transmittance, so as to improve the focus signal-to-noise ratio, ensure transmittance, Guaranteed concentrated effect of X-ray intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0049] The molybdenum / carbon non-periodic multilayer film is prepared by DC magnetron sputtering technology (Wang Fengli, Wang Zhanshan, Zhang Zhong, Wu Wenjuan, Wang Hongchang, Zhang Shumin, Qin Shuji, Chen Lingyan, 13 (2005) 28-33), ( Xu Yao, Wang Zhanshan, Xu Jing, Zhang Zhong, Wang Hongchang, Zhu Jingtao, Wang Fengli, Wang Bei, Qin Shuji, Chen Lingyan, 15 (2007) 1838-1843). Molybdenum thin film layers and carbon thin films are alternately deposited on germanium substrates to obtain molybdenum / carbon non-periodic multilayer film samples.

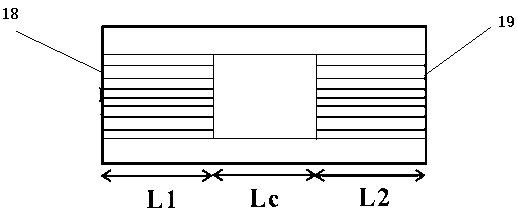

[0050] After the obtained molybdenum / carbon aperiodic multilayer film is further processed, the X-ray multilayer film waveguide is prepared. The steps are as follows, see attached figure 2 , Step A, deep processing the obtained multilayer film sample, and plating an anti-electron beam film on the sample film; Step B, using electron beam etching (E-beam) to etch a fixed width Lc at a specific position; Step C , Use ion beam etching (Reac

Example Embodiment

[0056] Example 1

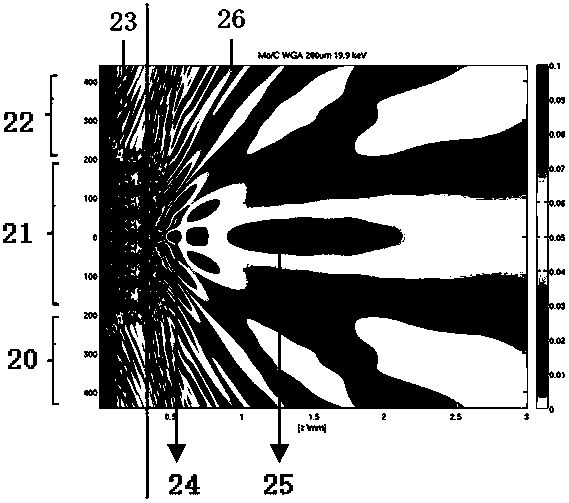

[0057] First, solve the relationship between the wave-derived emission phase and the thickness of a single conducting layer. Set this X-ray multilayer film waveguide to work at 19.9 keV energy, according to the calculation method of X-ray propagation in a single channel (C. Fuhse, T. Salditt, Physica B, 357 (2005) 57-60), by The Helmholtz equation of the ray at the entrance of the waveguide is solved, and the relationship formula between the propagation constant β and the thickness d of the guiding layer is obtained. , Where k0 is the wave vector in vacuum, n1 is the refractive index of the carbon film, and ξ is the characteristic value of the Helmholtz equation. Use Taylor's formula to expand this formula to obtain the relationship between the small thickness Δd and the small propagation constant Δβ.

[0058]

[0059] among them Is the waveguide parameter, n1 is the refractive index of the carbon film, n2 is the refractive index of the molybdenum film, β0 is the

Example Embodiment

[0066] Example 2

[0067] First, solve the relationship between the wave-derived emission phase and the thickness of a single conducting layer. Set this X-ray multilayer film waveguide to work at an energy of 19.9 keV, according to the calculation method of X-ray propagation in a single channel (C. Fuhse, T. Salditt, Physica B, 357 (2005) 57-60), by comparing X The Helmholtz equation of the ray at the entrance of the waveguide is solved, and the relationship formula between the propagation constant β and the thickness d of the guiding layer is obtained. , Where k0 is the wave vector in vacuum, n1 is the refractive index of the carbon film, and ξ is the characteristic value of the Helmholtz equation. Use Taylor's formula to expand this formula to obtain the relationship between the small thickness Δd and the small propagation constant Δβ.

[0068]

[0069] among them Is the waveguide parameter, n1 is the refractive index of the carbon film, n2 is the refractive index of the molybde

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap