Automatic-turning foldable deskboard and furniture

An automatic flipping and folding table technology, applied in the field of furniture, can solve the problems of flipping, folding, inconvenient operation, etc., and achieve the effect of simplifying operation and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

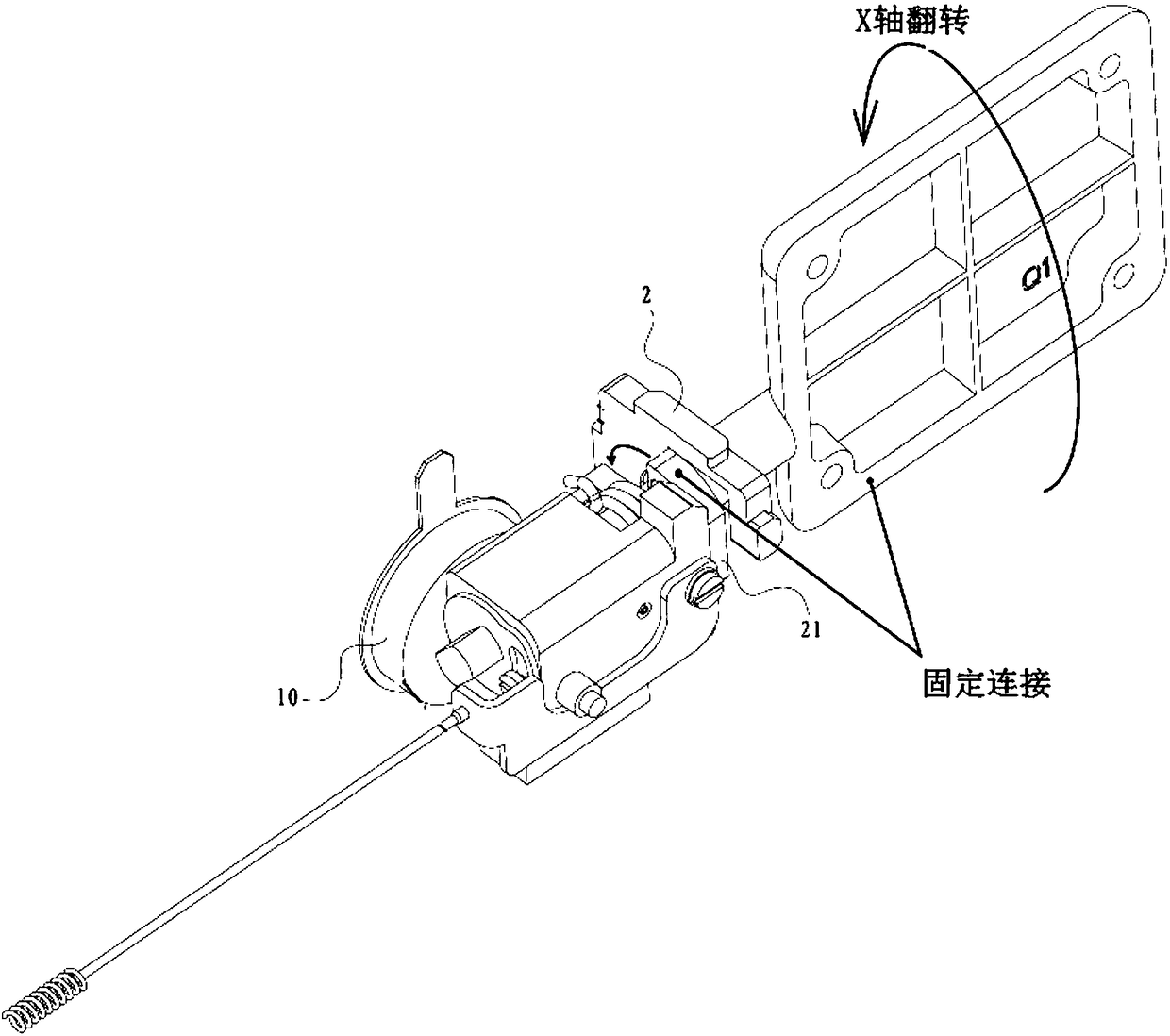

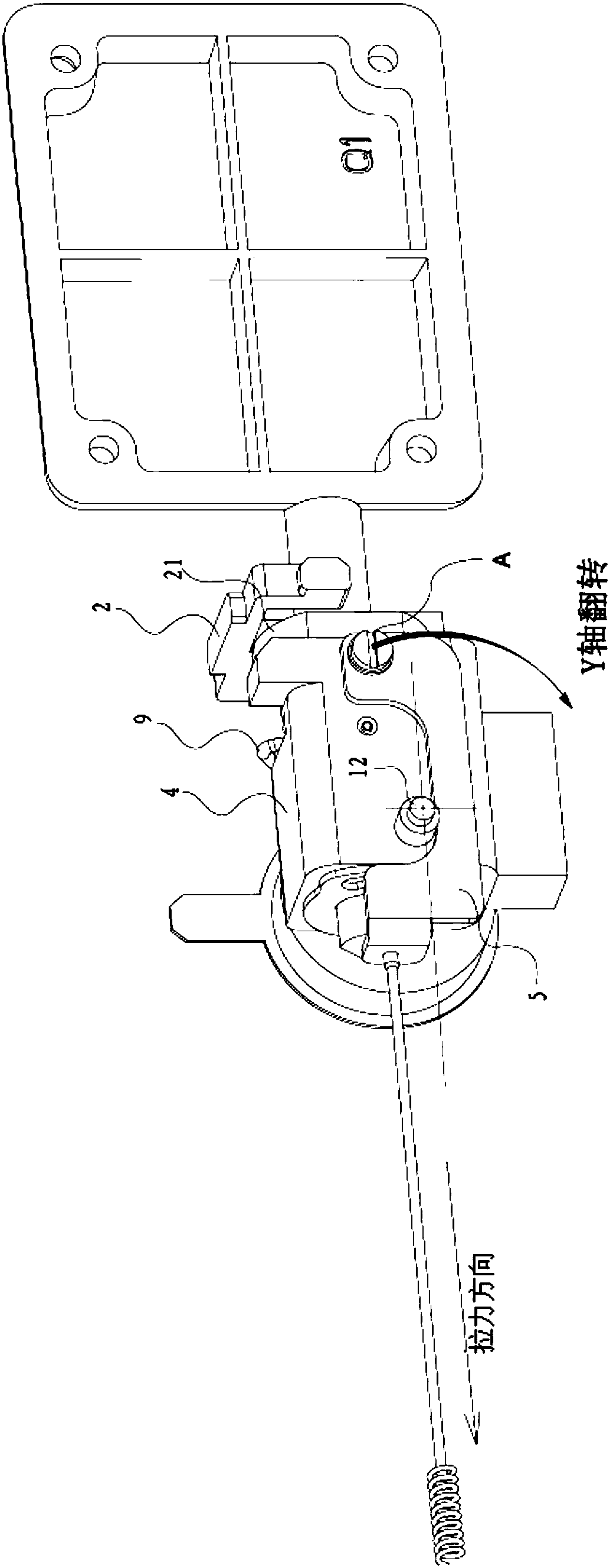

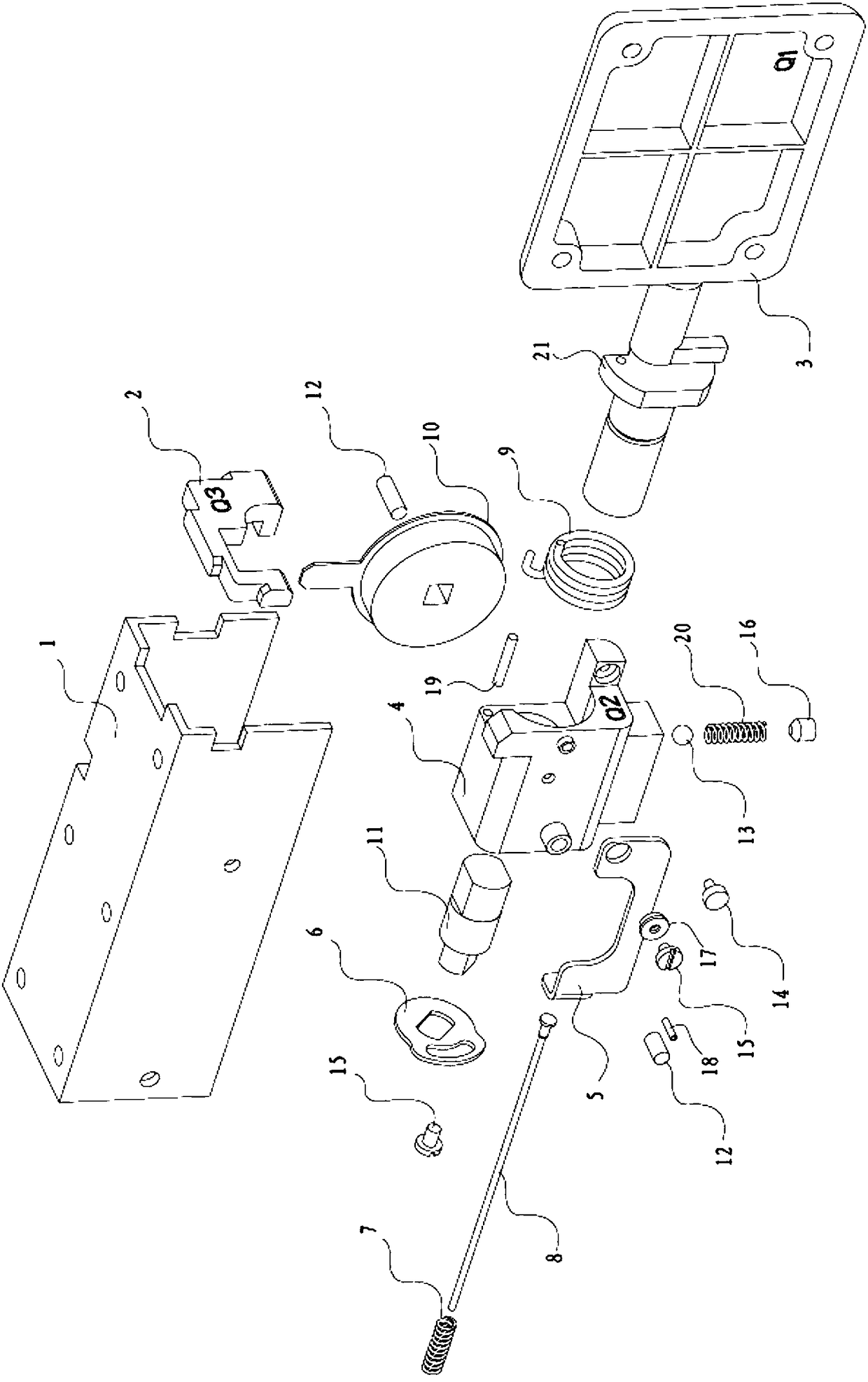

[0028] see Figure 1-Figure 6 , an automatic flipping and folding platen, including an X-axis turning mechanism, a Y-axis turning mechanism, a base block 4, and a baffle plate 2; the base block 4 and the baffle plate 2 are fixed; the X-axis turning mechanism includes a platen The connection mechanism 3, the limit block 21, the torsion elastic device, the limit block 21 and the rotating shaft of the platen connection mechanism are fixedly connected coaxially; Carry out plane locking, and then support the platen connecting mechanism 3; the torsion elastic device is arranged between the base block 4 and the platen connecting mechanism 3, and the torsion elastic device provides the torsion force to turn the platen connecting mechanism 3 to a horizontal state; The Y-axis turning mechanism includes a tension elastic device, a pull rod 8, and a draw plate 5. The pivot point A of the draw plate and the base block 4 is higher than the blocking point 12 for blocking the draw plate 5 on the

Embodiment 2

[0039] An automatic turning and folding table using the automatic turning and folding platen in the first embodiment; the specific structure and usage of the automatic turning and folding platen are the same as those in the first embodiment.

Embodiment 3

[0041] An automatic flipping and folding seat, which uses the automatic flipping and folding tabletop in the first embodiment; the specific structure and usage of the automatic flipping and folding tableboard are the same as those in the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap