Plastic part processing device

A processing device and technology of plastic parts, applied in the field of plastic plate processing, can solve the problem of non-adjustable width of the dust removal wipe head, and achieve the effect of enhancing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

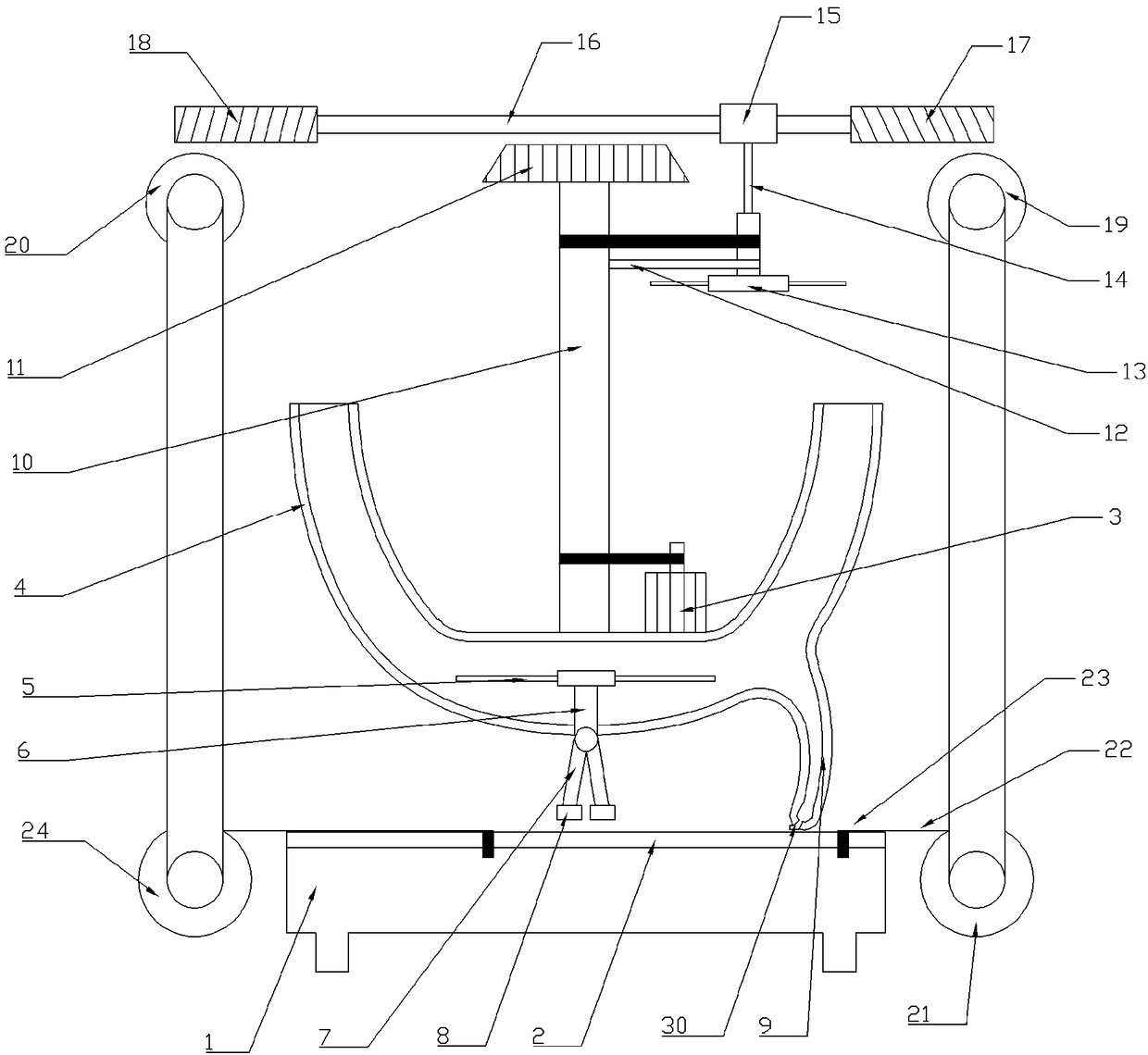

Embodiment 1

[0020] The embodiment is basically as attached figure 1 As shown: a plastic parts processing device, including a processing table 1 and a drive unit. In this embodiment, the drive unit is set as a motor 3, and a U-shaped tube 4 is arranged above the processing table 1, and a fan 5 is connected to the U-shaped tube 4 for rotation. , the lower end of the fan 5 is fixedly connected with a vertical rod 6 passing through the U-shaped pipe 4, and the vertical rod 6 is slidingly connected with the U-shaped pipe 4. When the fan 5 rotates, the vertical rod 6 can slide downward due to the wind force, and the vertical rod 6 The lower end of the U-shaped tube 4 is hingedly connected with several swing arms 7, the bottom of the swing arm 7 is provided with a dust removal wiper 8 for removing dust, the right side of the U-shaped tube 4 is provided with a branch pipe 9, and the tail end of the branch pipe 9 Several air outlets 30 are provided. A rotating shaft 10 is arranged above the U-shaped

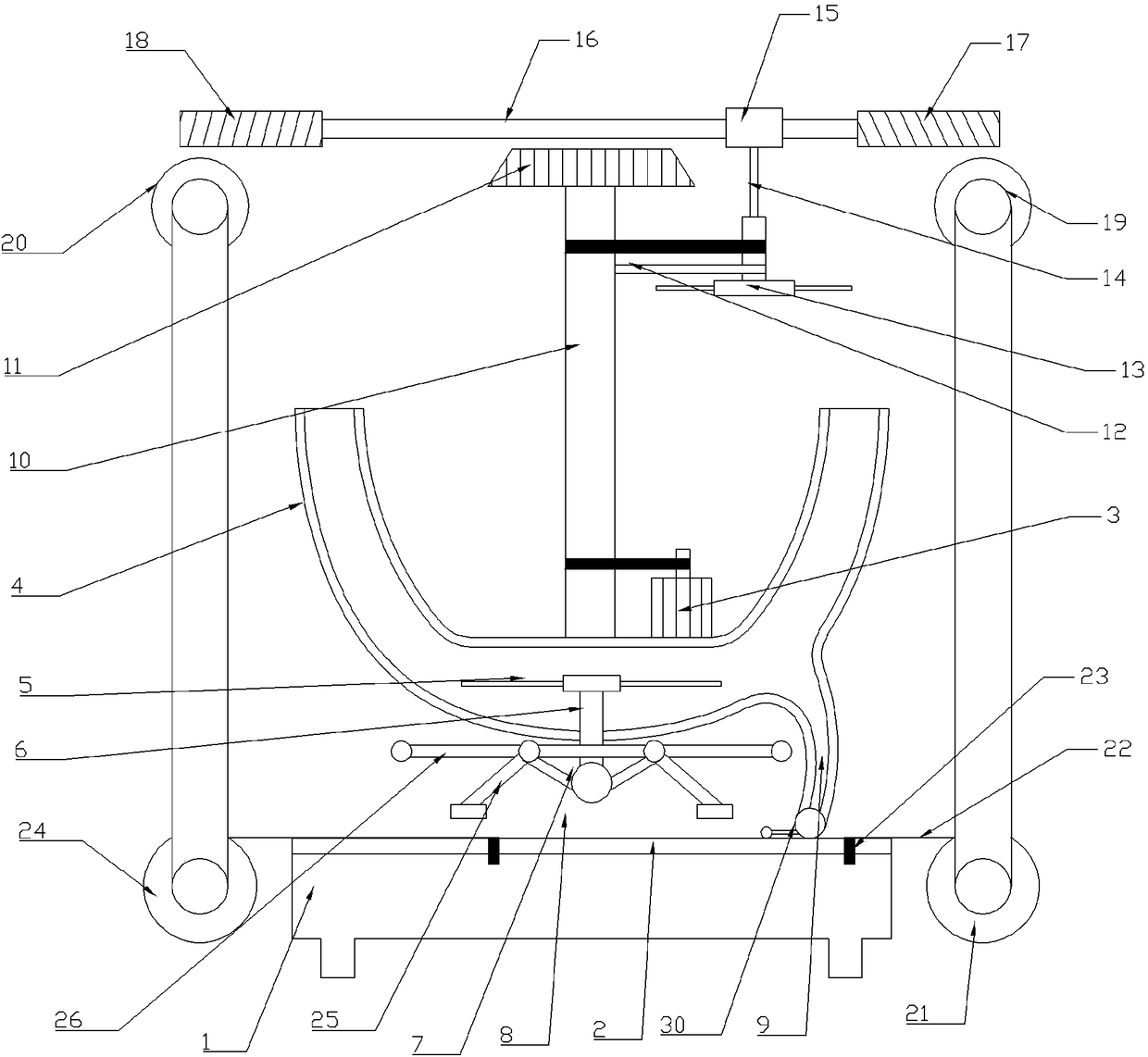

Embodiment 2

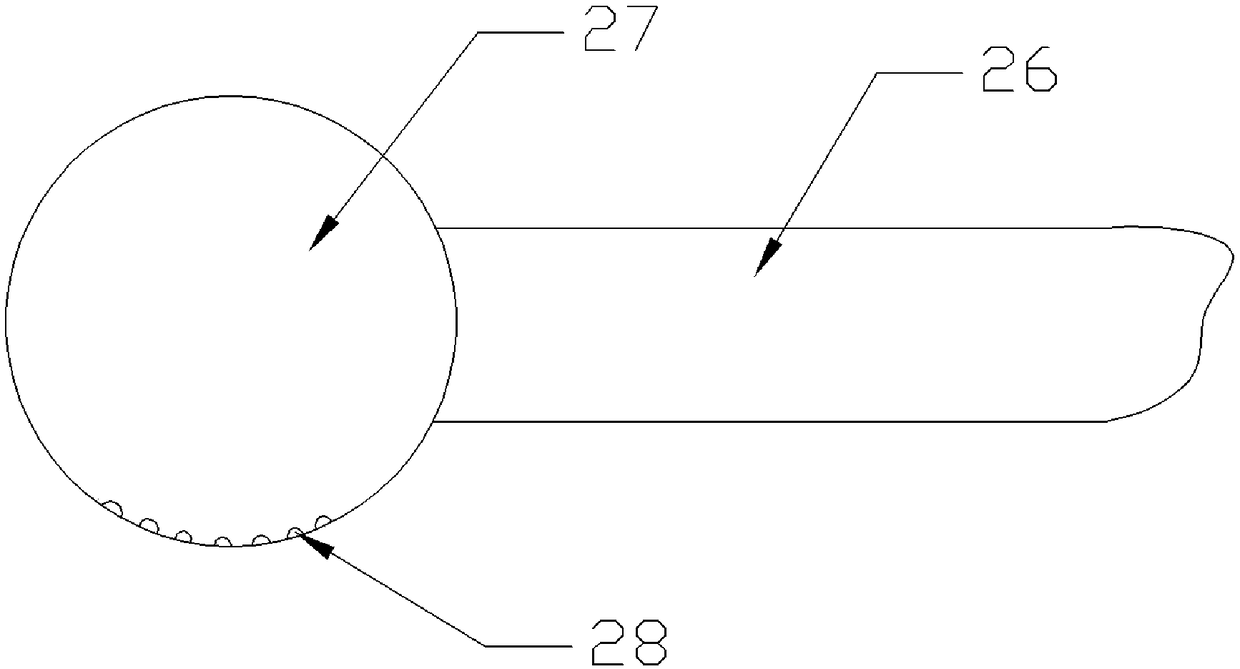

[0025] like figure 2 , image 3 and Figure 4 As shown, the difference between the present embodiment and the first embodiment is that the swing arm 7 at the lower end of the vertical bar 6 is M-shaped and includes four connecting rods 25 that are hinged to each other. The lower end of vertical bar 6 is also provided with slide rail 26, and two apexes of swing arm 7 are hinged on slide rail 26, and swing arm 7 middle parts are hingedly connected with vertical bar 6; The two ends of slide rail 26 are provided with water polo 27, as Figure 4 As shown, some nozzle holes 28 are also arranged on the water polo 27 , when the water polo 27 is squeezed, the water flow will flow out from the nozzle holes 28 .

[0026] During specific implementation, the swing arm 7 is set to an M shape, and the apex of the swing arm 7 is hinged on the slide rail 26. As the wind force size of the fan 5 in the U-shaped pipe 4 changes, the two apexes of the swing arm 7 are in the chute. Slide left and r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap