Multi-hinge type anti-blocking elastic clamp positioning mechanism

A technology for preventing dead bullets from the top and positioning mechanism, which is applied in the direction of extraction of undisturbed cores, earth-moving drilling, etc., can solve the problems of inability to salvage inner pipe drilling tools, lower drilling tools bits falling off, accidents in holes, etc., and achieves good practicality. Value and market promotion prospects, the effect of reducing labor intensity and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

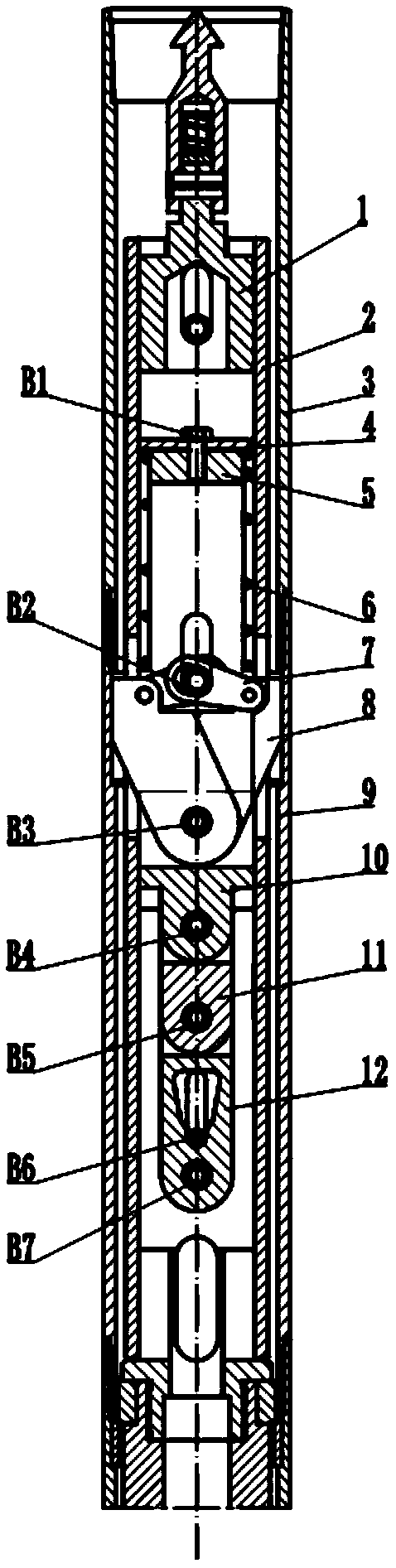

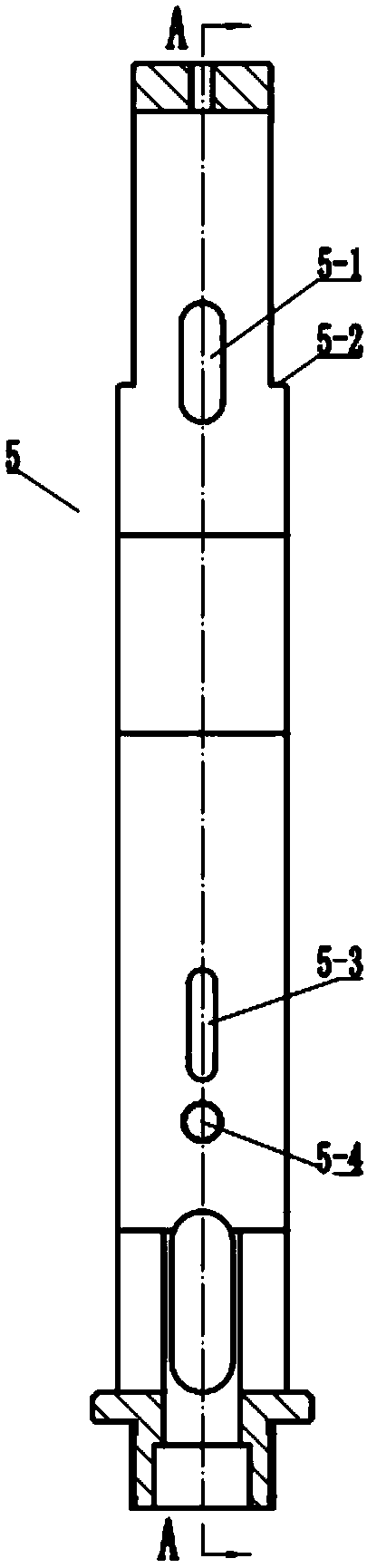

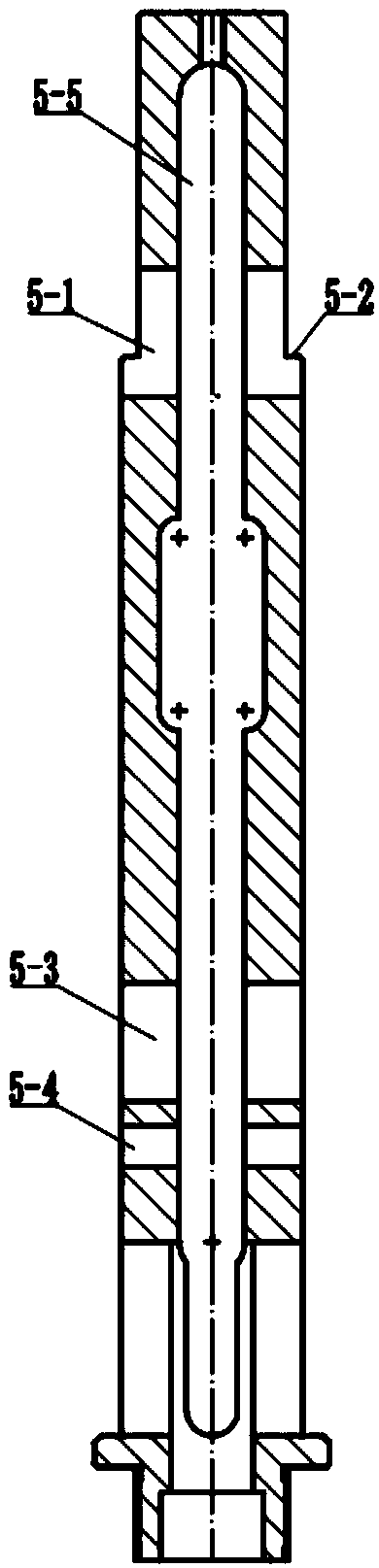

[0018] See Figure 1, Figure 4 , the present invention is a multi-joint hinge type anti-top dead bullet clamp positioning mechanism, which includes a recovery tube 2, a bullet clamp frame 5, a pull-back plate 7, a bullet caliper 8, a bullet clamp seat 10, a middle hinge 11, and a lower hinge 12 , the first elastic pin B2, the second elastic pin B3, the third elastic pin B4, the fourth elastic pin B5, the fifth elastic pin B6 and the sixth elastic pin B7; the upper end of the recovery pipe 2 is assembled with the spear head assembly 1, In the recovery pipe 2, the bullet holder 5 is equipped, and the first elastic pin B2 is fixedly installed on the top of the recovery pipe 2, and the fifth elastic pin B6 is fixedly installed on the bottom of the recovery pipe 2; The pliers body, the left and right pliers are hingedly assembled with the cartridge 10

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap