Installation structure for airplane oxygen bottle

A technology for installation structures and oxygen cylinders, which is applied to aircraft parts, mechanical equipment, transportation and packaging, etc., can solve the problems that cannot meet the requirements of disassembly and maintenance of oxygen cylinders, and achieve the effect of light weight, firm connection and low installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

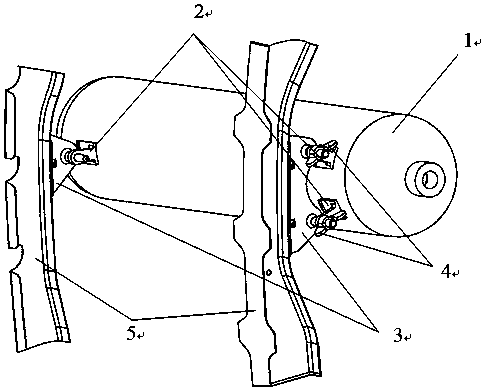

[0022] An aircraft oxygen cylinder installation structure, which includes: oxygen cylinder 1, ear piece 2, bracket 3, wing nut 4;

[0023] The ear piece 2 is fixed on the oxygen cylinder 1, and the bracket 3 is fixed on the fuselage structure 5;

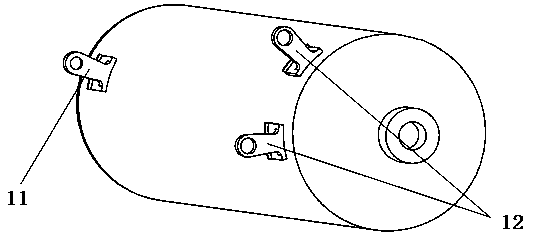

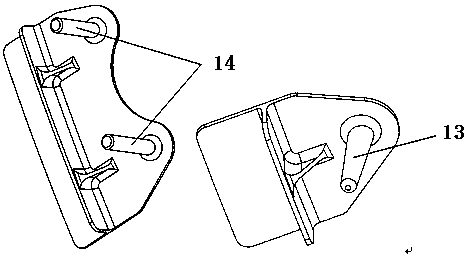

[0024] The ear piece 2 is divided into an ear piece 11 with a tapered hole and an ear piece 12 with a bolt hole and is respectively located at both ends of the oxygen cylinder 1, and the bracket 3 is divided into a tapered pin bracket 13 and a stud bracket 14, The tapered pin support 13 is connected and fixed with the lug 11 with the tapered hole, and the stud support 14 is connected and fixed with the lug 12 with the bolt hole;

[0025] The wing nut 4 fixes the stud bracket 14 .

[0026] Further, the number of lugs 11 with tapered holes is one, and the number of lugs 12 with bolt holes is two.

[0027] Further, the ear pieces 2 are

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap