Tread profile for vehicle tyre and tyre in winter with the thread

A winter tire and pattern technology, applied in the direction of tire tread/tread pattern, vehicle parts, tire parts, etc., can solve the problems of increasing tire production cost, hindering tire sipes, complex patterns, etc., to achieve good traction and Effects of Brake Response Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

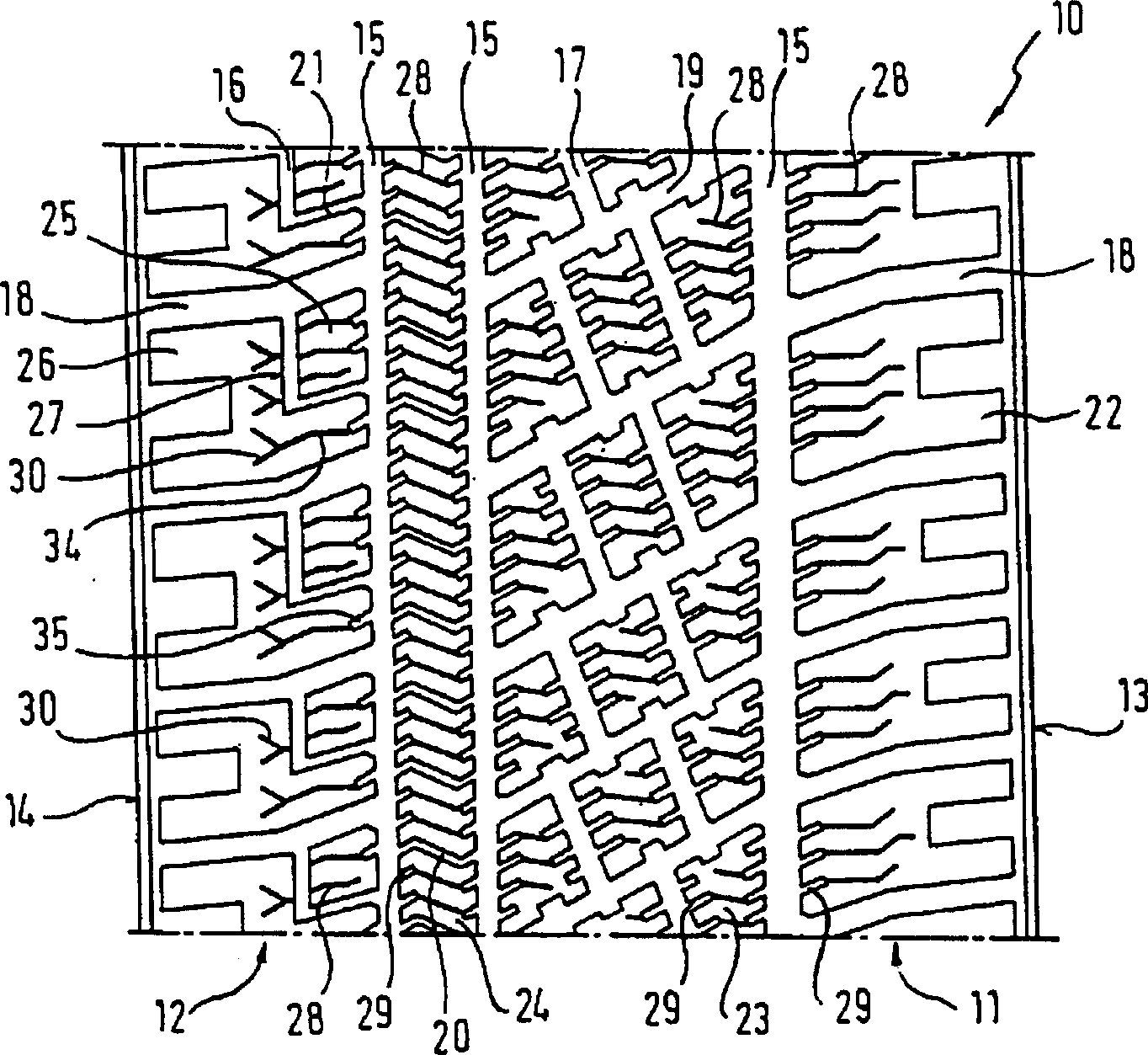

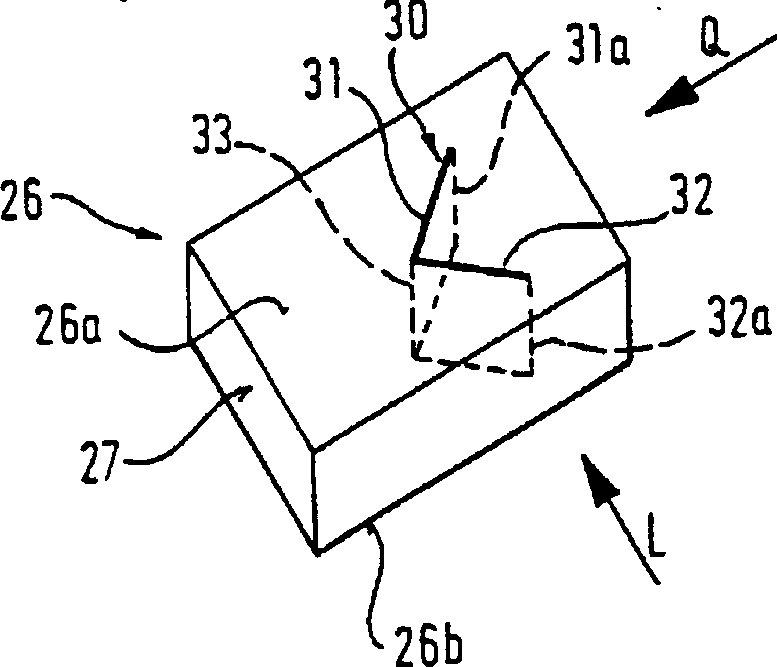

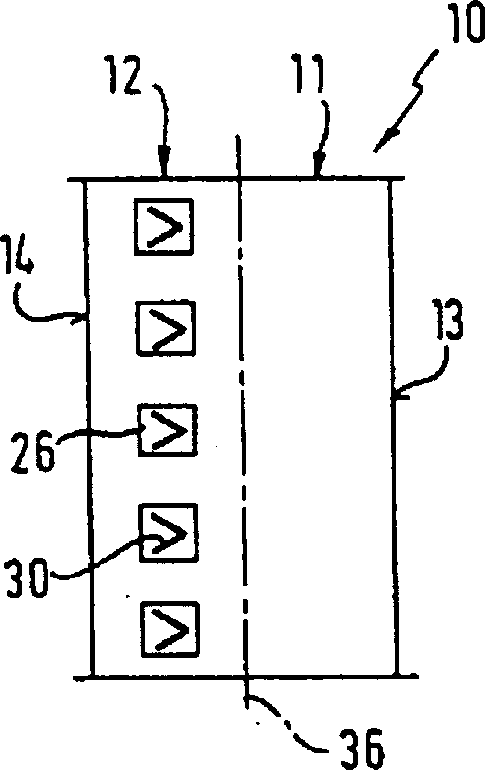

[0024] refer to figure 1 The plan view shown shows a pattern 10 having longitudinal grooves 15,16. Also provided is a longitudinal groove 17 oriented slightly obliquely to the direction of circumferential extension of the pattern 10 . The longitudinal grooves 16 do not extend continuously across the entire pattern 10, but are instead separated by sections of squares 26 in the pattern.

[0025] The respective longitudinal grooves 15, 16, 17 are separated by transverse grooves 18, 19, 20, 21, which are arranged vertically or slightly obliquely to the longitudinal grooves 15, 16, 17, the longitudinal grooves 15, 16, 17 and the transverse grooves 18, 19, 20, 21 define blocks 22, 23, 24, 25, 26 in the pattern pattern. In this arrangement the blocks 22, 26 formed on the inner and outer shoulders 11, 12 of the pattern 10 are larger, while the blocks 23, 24 formed in the central part of the pattern 10 are smaller. The square 25 which is likewise provided in the area of the outer sho

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap