Integrated system and control method for achieving heat exchange and power generation through liquid nitrogen

An integrated system, electromagnetic control valve technology, applied in heat exchanger types, indirect heat exchangers, machines/engines, etc., can solve problems such as the inability to dissipate the heat of the internal combustion engine cylinder normally, the increased heat load of components, and the hidden danger of internal combustion engine safety. , to achieve the effect of obvious cooling effect, short cooling time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

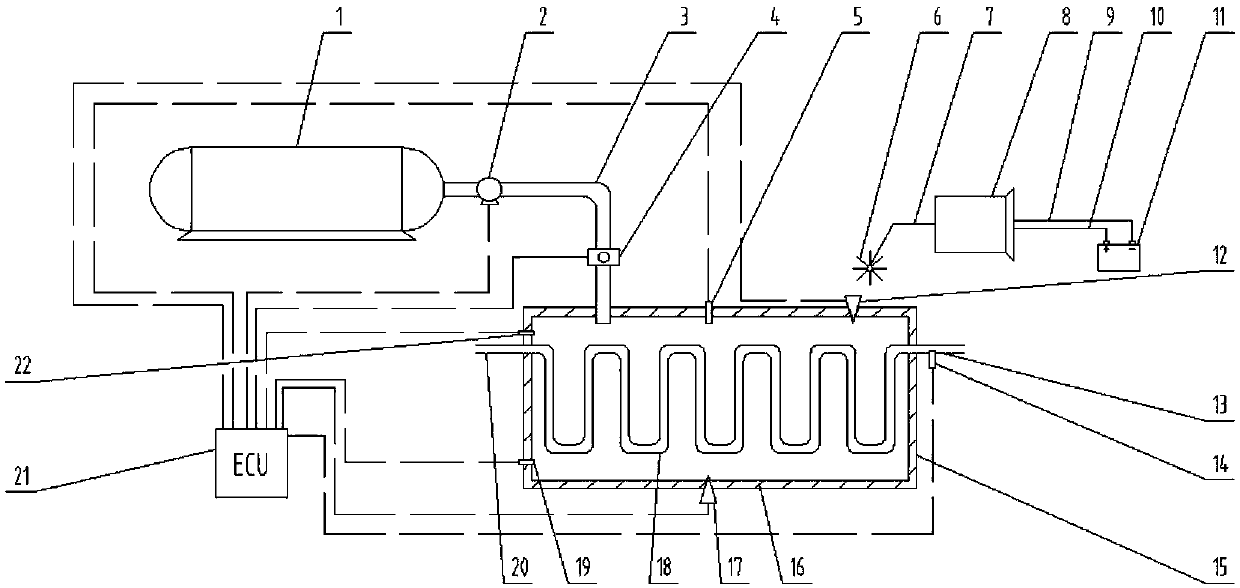

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

[0021] As shown in the accompanying drawings, a heat exchange-power generation integrated system using liquid nitrogen of the present invention includes an electronic control unit ECU21, and the outlet of the high-pressure nitrogen storage tank 1 is sequentially connected to the liquid nitrogen pump 2 and the first through the liquid nitrogen pipeline 3. The electromagnetic control valve 4 and the outlet of the liquid nitrogen pipeline 3 are inserted into the liquid nitrogen inlet on the top of the heat exchange box 15 to set.

[0022] A heat exchange pipeline 18 for transporting heat exchange fluid is installed in the heat exchange box 15, and the inlet and outlet of the heat exchange pipeline 18 extend out from the left and right sides of the heat exchange box 15 respectively. The inlet of the heat exchange pipeline is connected to the outl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap