Directional solidification casting mold device

A technology of directional solidification and casting mold, applied in the field of casting equipment, can solve the problems of short cooling time, low cooling efficiency, long cooling time, etc., and achieve the effects of short cooling time, high cooling efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] In the following, the present invention will be further described through embodiments with reference to the drawings.

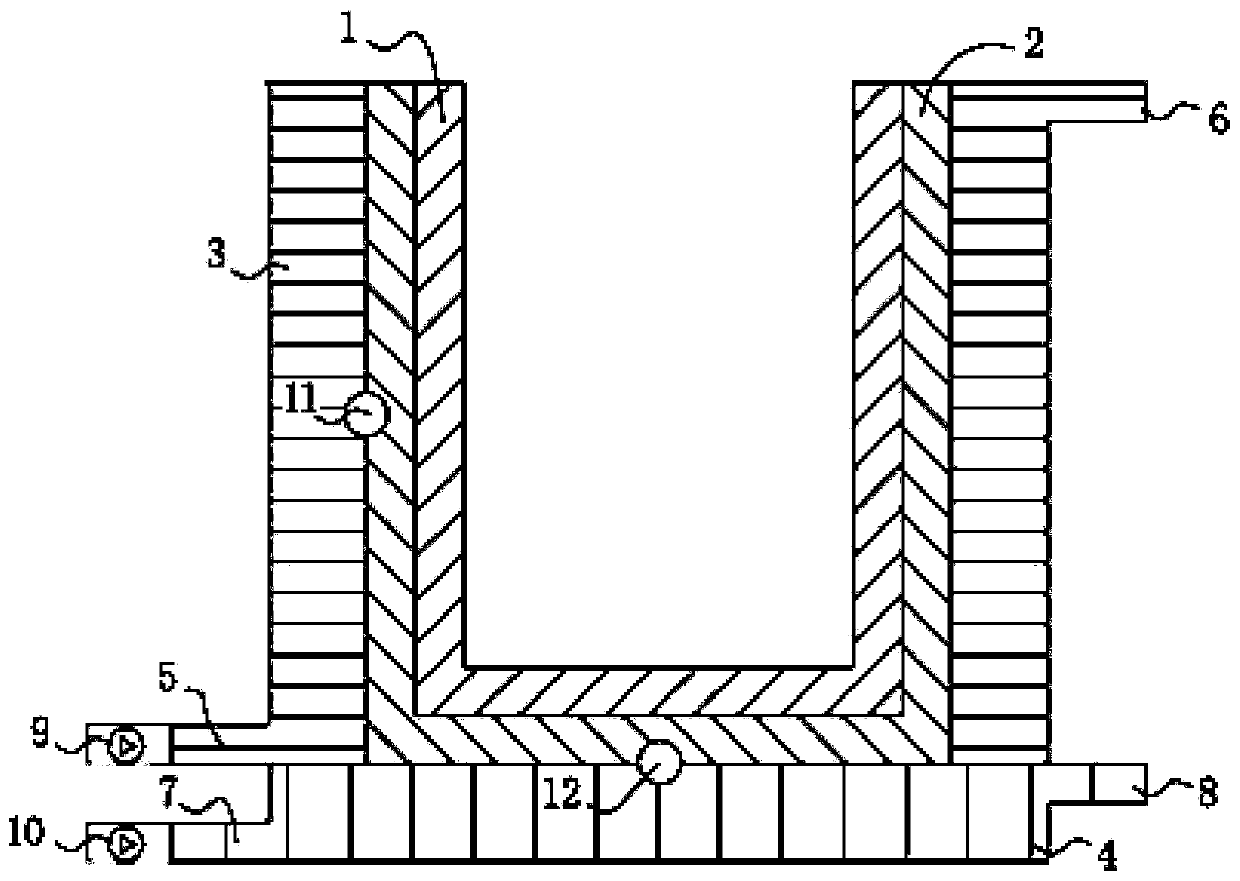

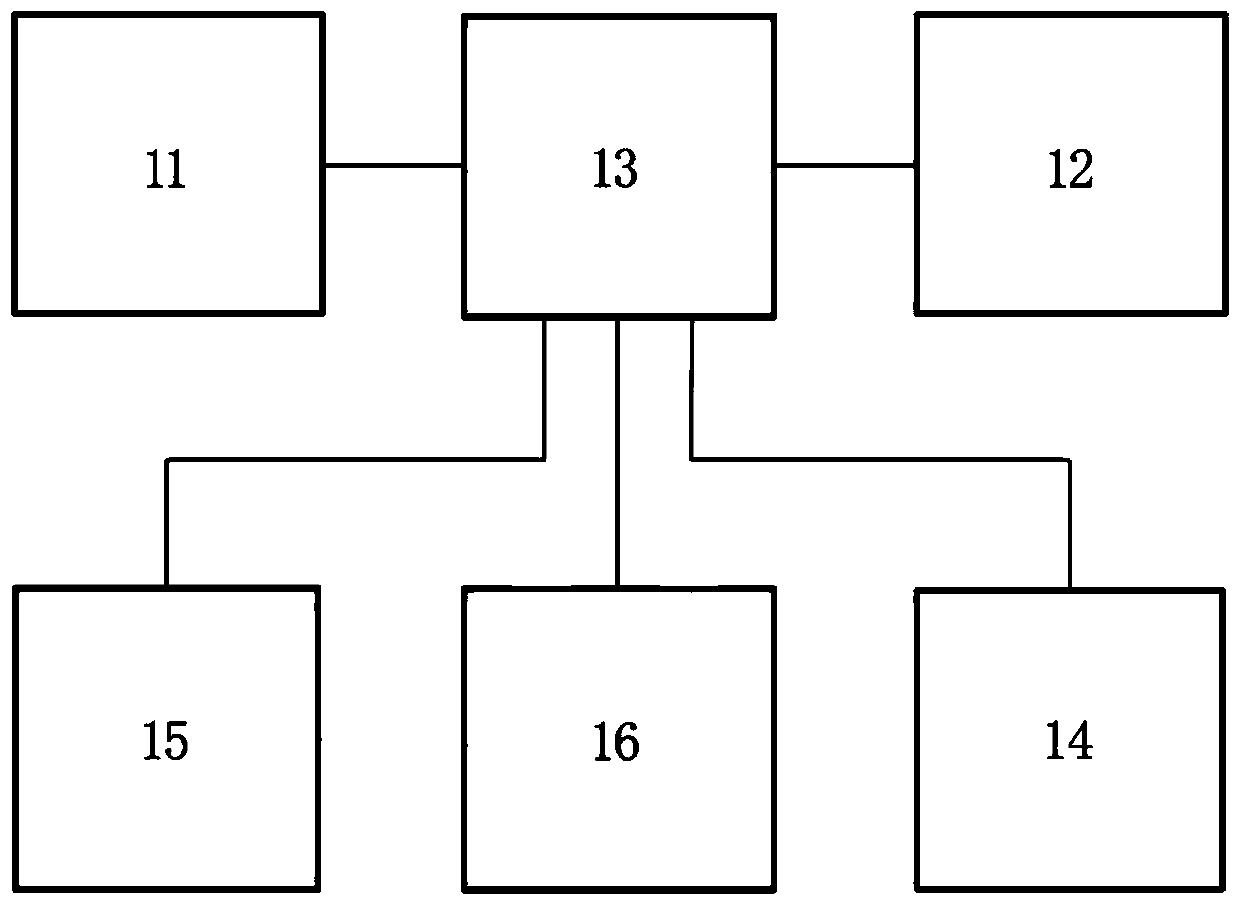

[0017] Reference attached figure 1 And figure 2 , A directional solidification casting mold device, comprising an inner barrel 1, a heat-conducting barrel 2, a radial water cooling device 3 and a bottom water cooling device 4. The inner barrel 1 is set in the heat-conducting barrel 2, and the outer side of the inner barrel 1 and the inner wall of the heat-conducting barrel 2 The outer end surface of the bottom of the inner barrel 1 and the inner surface of the bottom of the heat conducting barrel 2 are tightly attached together; in order to obtain a good surface quality ingot, the inner barrel 1 uses a graphite barrel; To quickly transfer the heat of the ingot to improve the cooling capacity of the device, the heat-conducting barrel 2 is made of a metal material with high thermal conductivity. Preferably, the heat-conducting barrel 2 is a copper barrel, whe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap