Single-point incremental forming technology for non-axisymmetric step-feature forming part

A non-axisymmetric, single-point progressive technology, applied in the field of mechanical engineering, to achieve the effect of reducing production costs, reducing mutual influence, and improving geometric accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

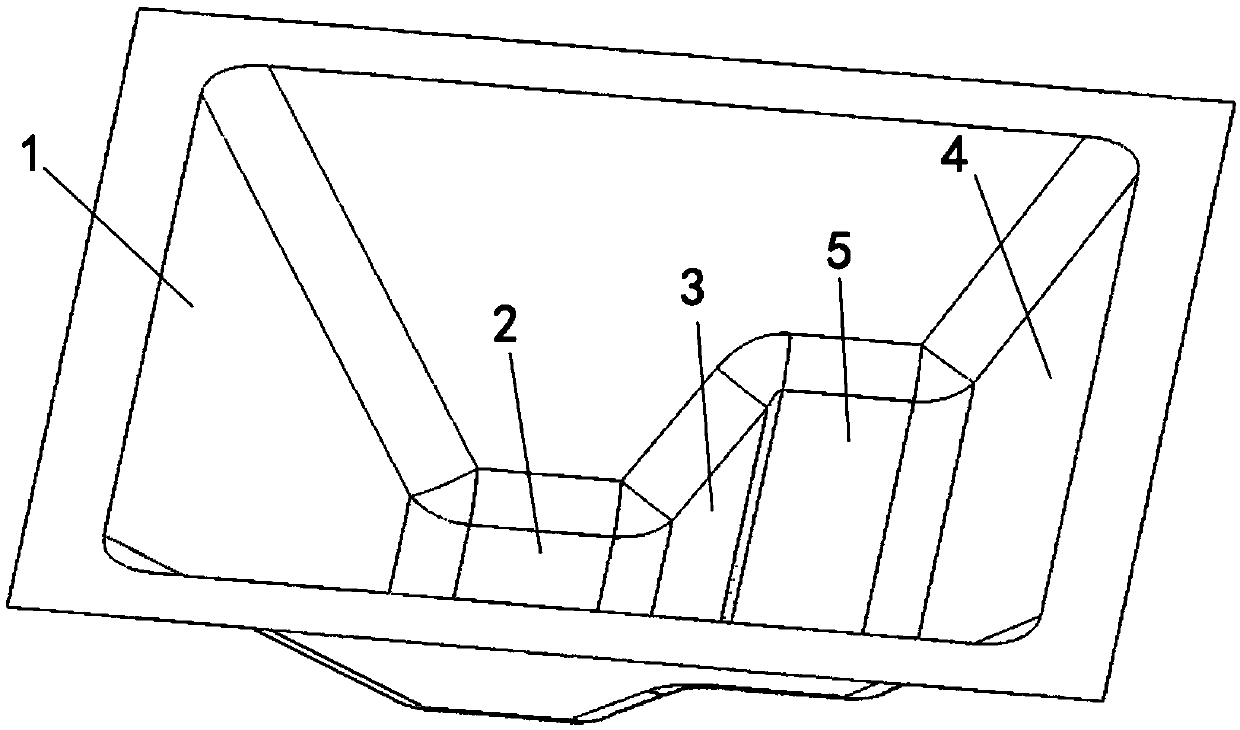

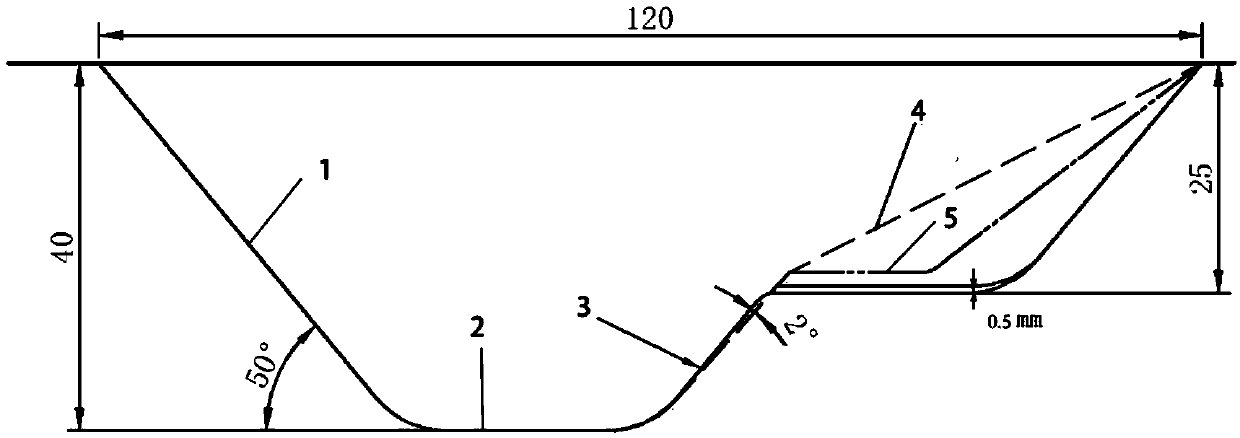

[0025] Such as figure 1 and figure 2 As shown, this embodiment provides a single point incremental forming process for a non-axisymmetric stepped feature molding. Clamp the planar sheet metal parts in the air, use the tool head to process the sheet metal parts into formed parts through multi-pass processes, and reasonably design the processing track of each pass, so that the step slopes 3 and 4 in the formed parts are formed The sequence precedes the shaping of the stepped plane 5 . In this embodiment, a planar aluminum alloy sheet is processed into a molded part with non-axisymmetri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap