Hyperboloidal sewage stirrer

A hyperboloid and agitator technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, mixers with rotating agitation devices, etc., can solve the problem that the mixing effect is not particularly ideal, and low speed and high efficiency cannot be achieved. , high cost of the aerator, etc., to achieve the effect of increasing the stirring effect, improving the pushing flow ability, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

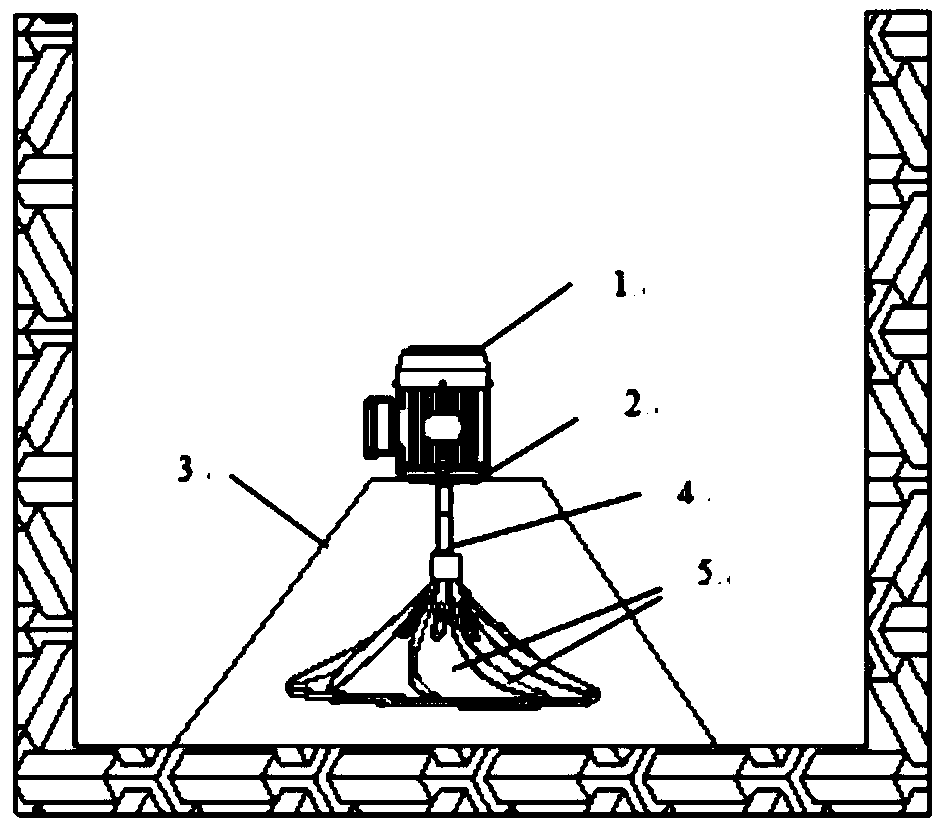

[0027] Such as figure 1 As shown, this embodiment provides a hyperboloid sewage agitator, including a support structure, a driving device and a stirring part 5; the supporting structure is arranged in the sewage tank, the driving device is arranged on the top of the supporting structure, and the driving device is used to drive the stirring part 5 .

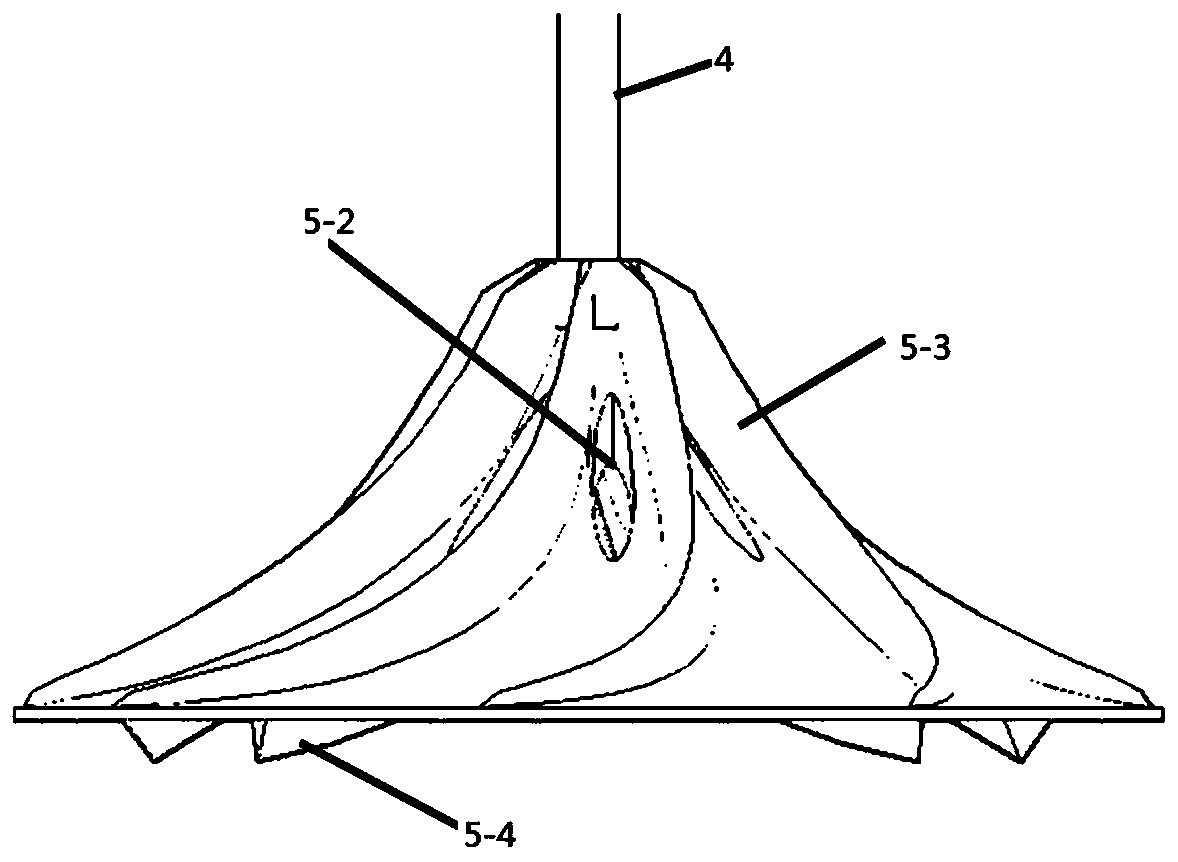

[0028] In this specific embodiment, the supporting structure includes a supporting frame 3 , and the driving device is arranged on the top of the supporting frame 3 . The driving device is the motor 1. The stirring part 5 is arranged on the power output shaft of the motor 1 . The stirring part 5 includes a hub and eight guide paddles 5-3; the eight guide paddles 5-3 are uniformly arranged on the upper surface of the hub. The hub is a flared structure with the smaller end of the hub at the top. The upper part of the hub is provided with eight discharge ports 5-2. The discharge port 5-2 is located between adjacent guide paddles 5-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap