Transnasal high-flow oxygen therapy device

A high-flow, oxygen therapy technology, applied in the field of oxygen therapy instruments, can solve the problems of difficulty in adjusting the height of the airway, poor telescopic stability of the bracket rod, and poor clamping stability of the airway, so as to improve convenience and stability. and flexibility, the effect of increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

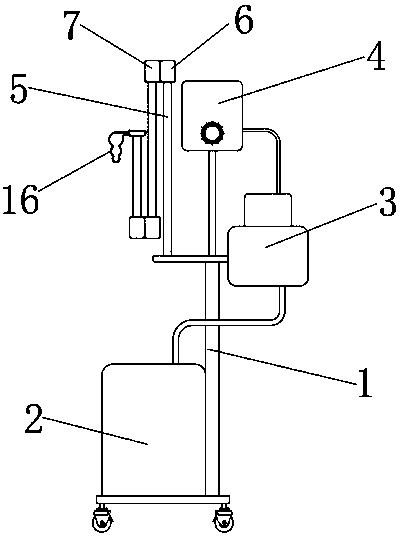

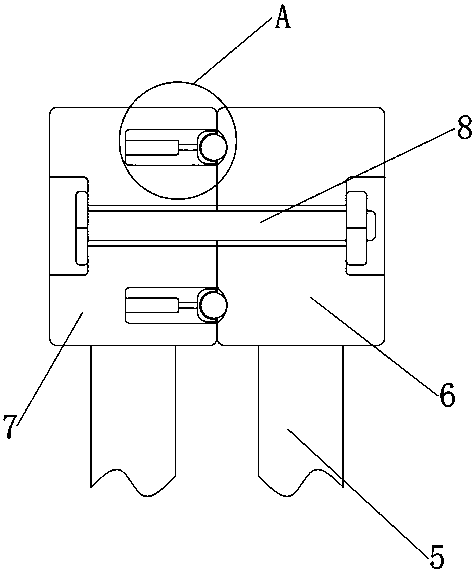

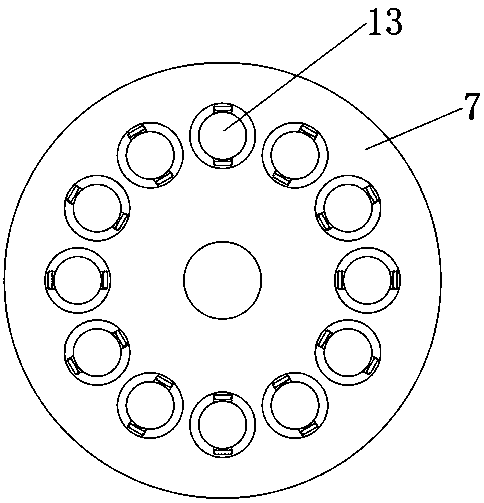

[0025] see Figure 1-7 , the present invention provides the following technical solutions: a nasal high-flow oxygen therapy device, comprising a bracket 1, an air compressor 2, a humidification water tank 3 and an air mixer 4, the air compressor 2, a humidification water tank 3 and an air mixer The devices 4 are all fixed on the surface of the support 1, and the surface of the support 1 is also fixed with a bracket rod 5, and the joints of the bracket rod 5 are provided with a sub-rotation shaft 6 and a female rotation shaft 7, and there is a connection between the sub-rotation shaft 6 and the female rotation shaft 7 The surface of the bolt 8 and the female rotating shaft 7 is provided with a movable groove 9, an outer casing 10 is installed inside the movable groove 9, a compression spring 11 is installed inside the outer casing 10, and a telescopic rod 12 is installed on the outer casing 10 through the compression spring 11. One end of the telescopic rod 12 is connected with a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap