Winch bushing temperature measurement device

A temperature measuring device and bushing technology, applied in the field of mechanical equipment, can solve problems such as bushing and spindle sticking, damage to mooring winch, etc., and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

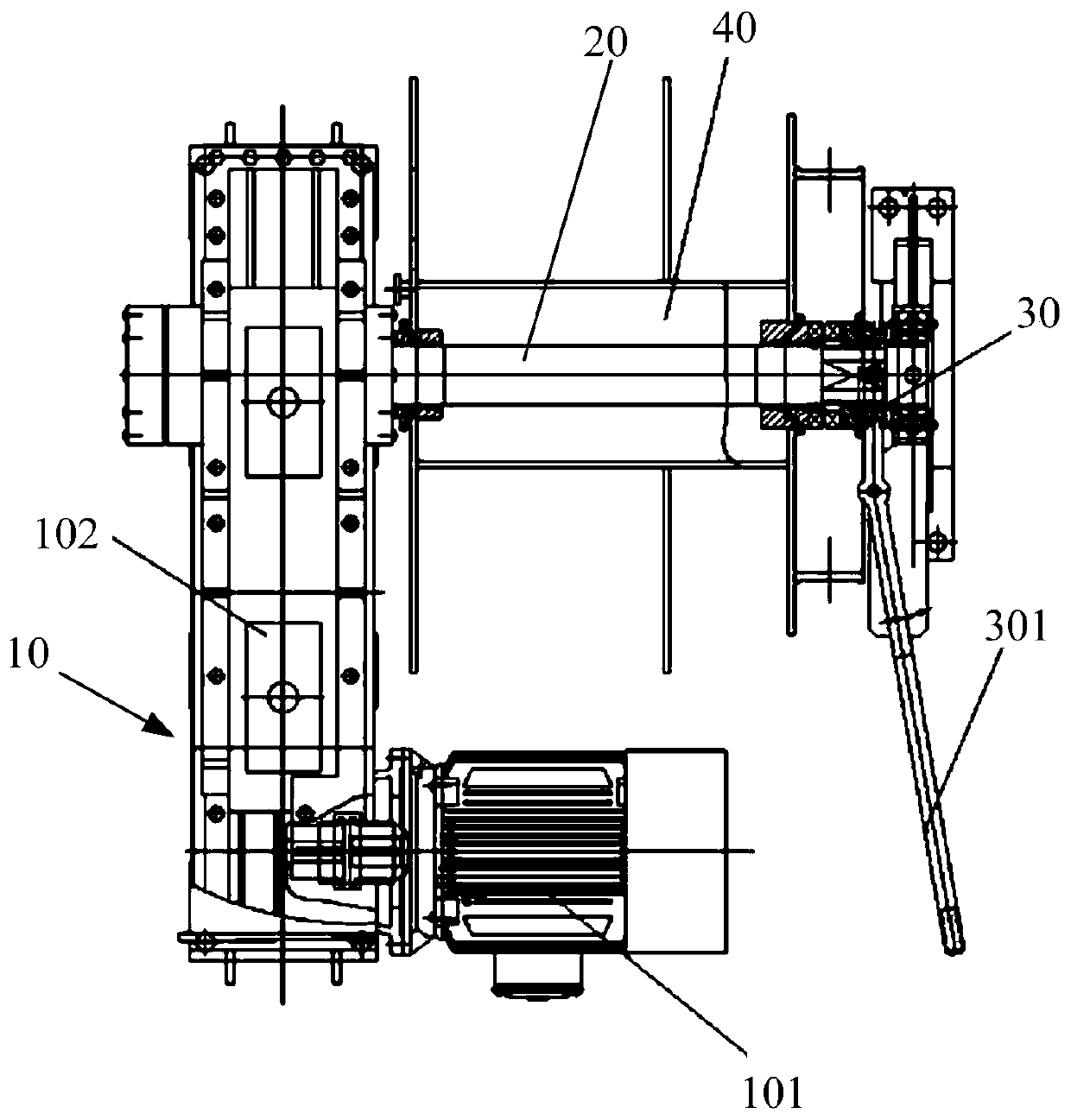

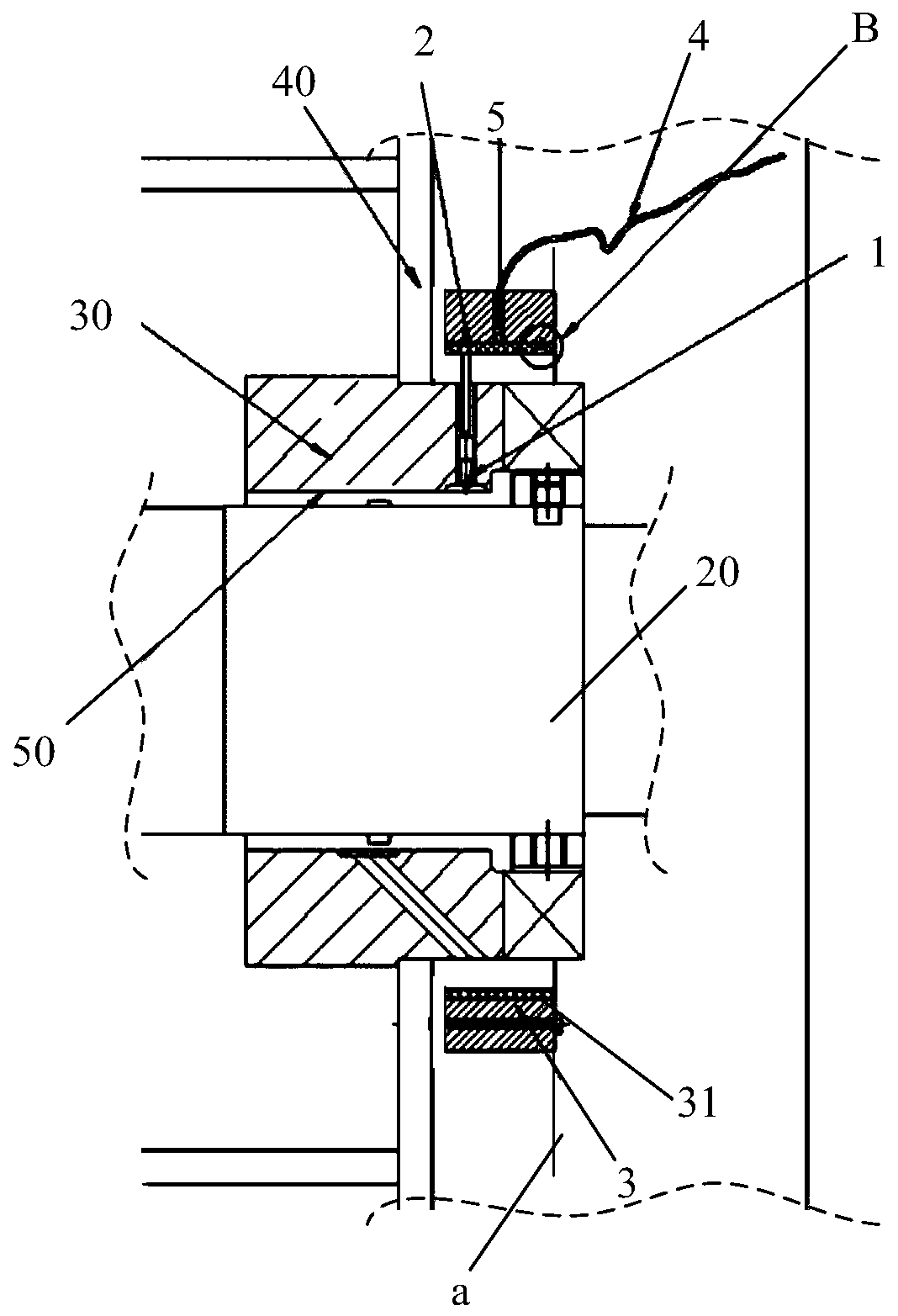

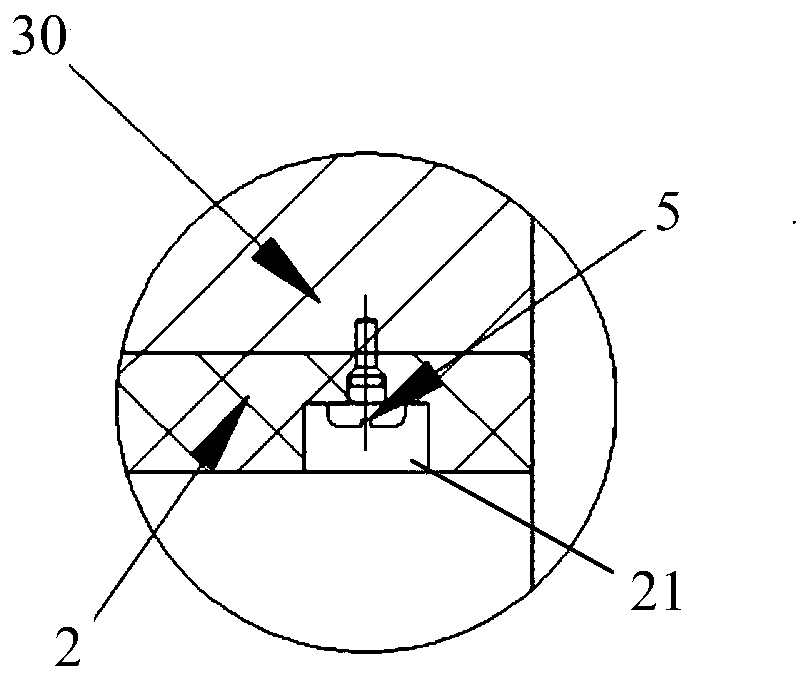

[0024] figure 1 It is a structural schematic diagram of a winch provided by an embodiment of the present invention. For ease of understanding, we can first figure 1 Understand the structure of the winch shown in . Such as figure 1 As shown, the mooring winch mainly includes a driving structure 10 , a main shaft 20 , a clutch 30 and a drum 40 . The driving structure 10 is connected to one end of the main shaft 20 , the other end of the main shaft 20 is connected to the clutch 30 , and the roller 40 is coaxially sleeved on the main shaft 20 . When the clutch 30 is disengaged, the clutch 30 and the drum 40 are separated from the main shaft 20. When the clutch 30 is closed, the clutch 30 and the drum 40 are connected to the main shaft 20, and the c

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap