Inverter system for vehicle

A technology for inverters and vehicles, used in control systems, vehicle components, vehicle energy storage, etc., to solve problems such as excessive switching losses and conduction losses, and reduced fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

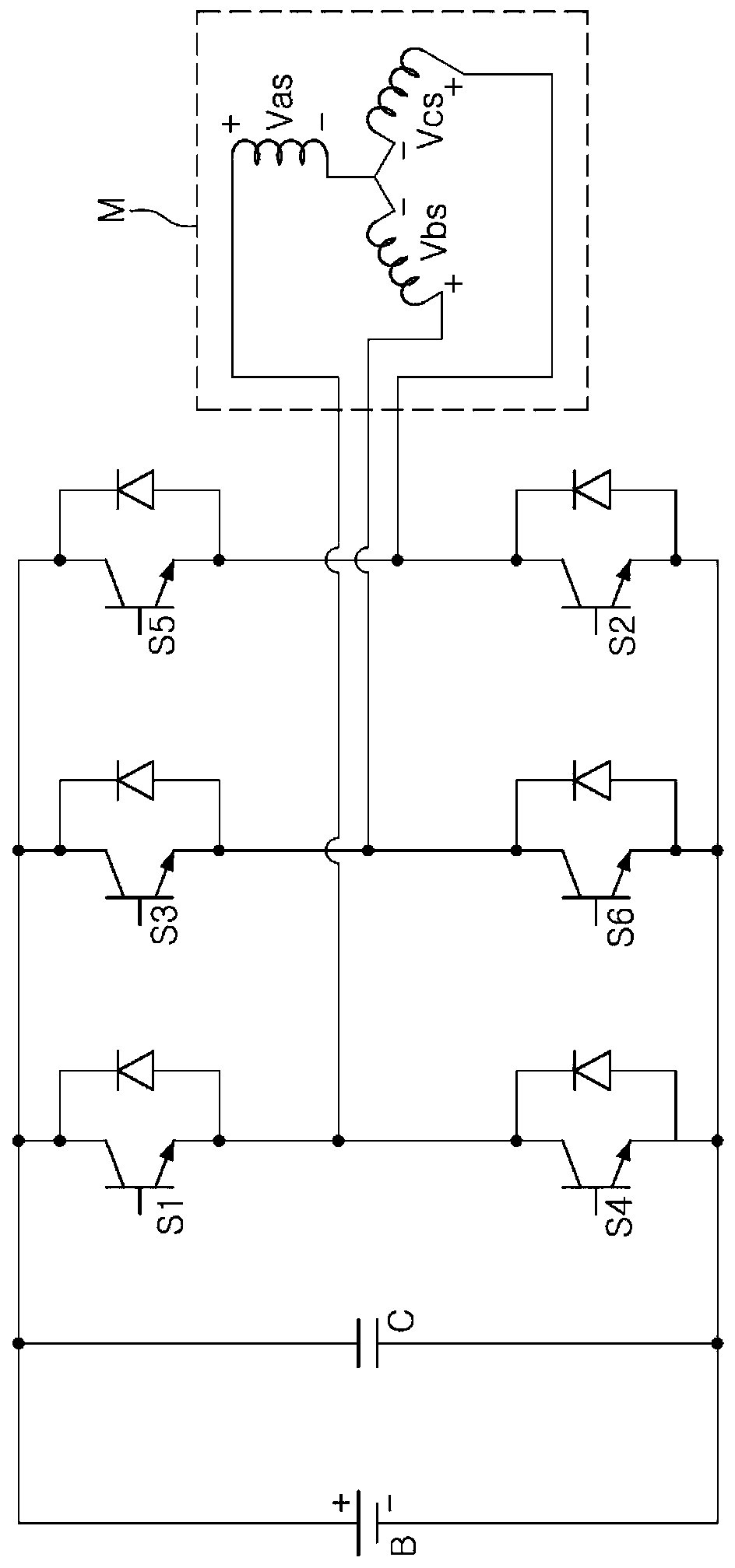

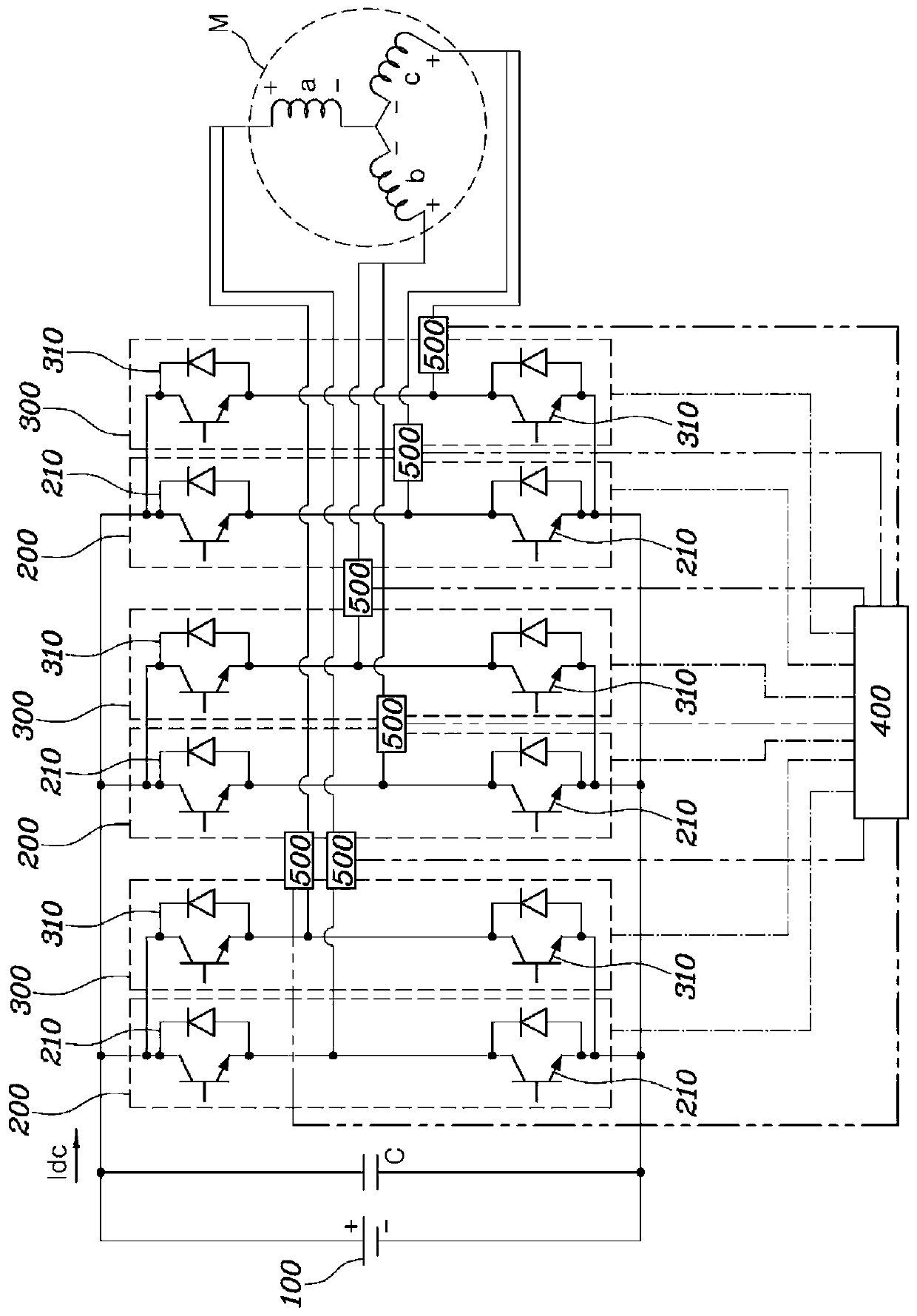

[0023] Hereinafter, an inverter system for a vehicle according to an exemplary embodiment of the present disclosure will be described with reference to the accompanying drawings.

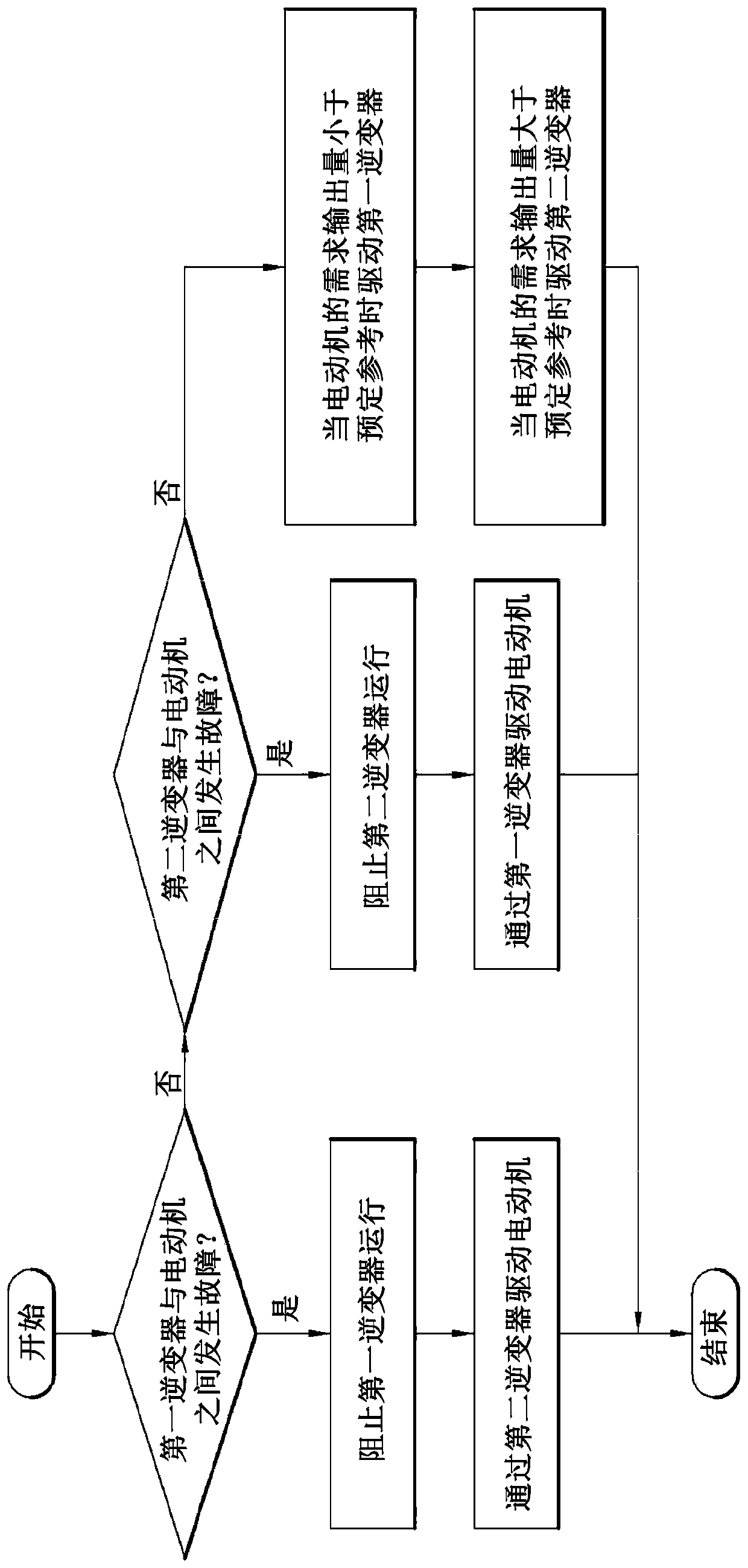

[0024] figure 2 is a diagram showing an inverter system for a vehicle according to an embodiment of the present disclosure, image 3 is a flow chart showing a flow of driving the motor by the first inverter or the second inverter according to the position where a fault occurs between the first inverter and the second inverter and the motor, and Figure 4 is a diagram showing pulse width modulation (PWM) signals input to the first inverter and the second inverter when the required output amount of the motor is greater than a reference.

[0025] Such as figure 2 As shown in , an inverter system for a vehicle according to an embodiment of the present disclosure may include an energy storage device 100, a first inverter 200, a second inverter 300, a motor M, a controller 400, and a current sensor 500.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap