Lapping and polishing machine and polishing process thereof

A polishing machine, No. 1 technology, applied in the field of polishing machines, can solve problems such as low assembly efficiency, and achieve the effect of ensuring a stable position and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

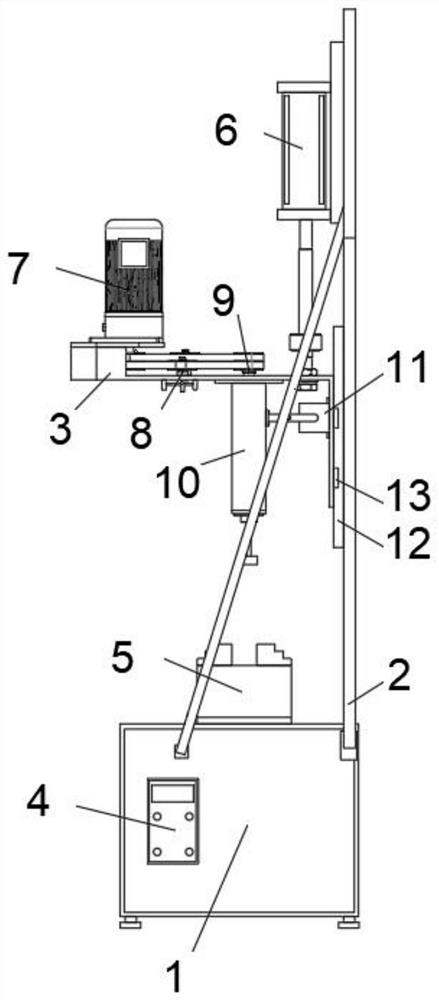

[0032] Attached below. Figure 1 Further, the specific embodiment of the grinding and polishing machine and its polishing process of the present invention will be described. The grinding and polishing machine of the present invention and its polishing process are not limited to the description of the following embodiments.

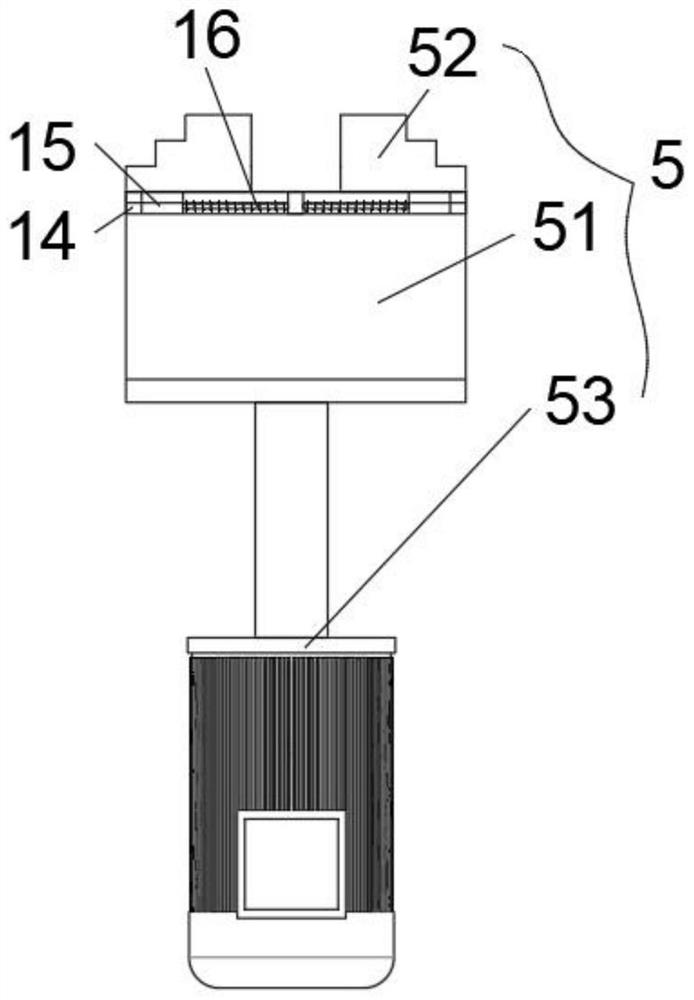

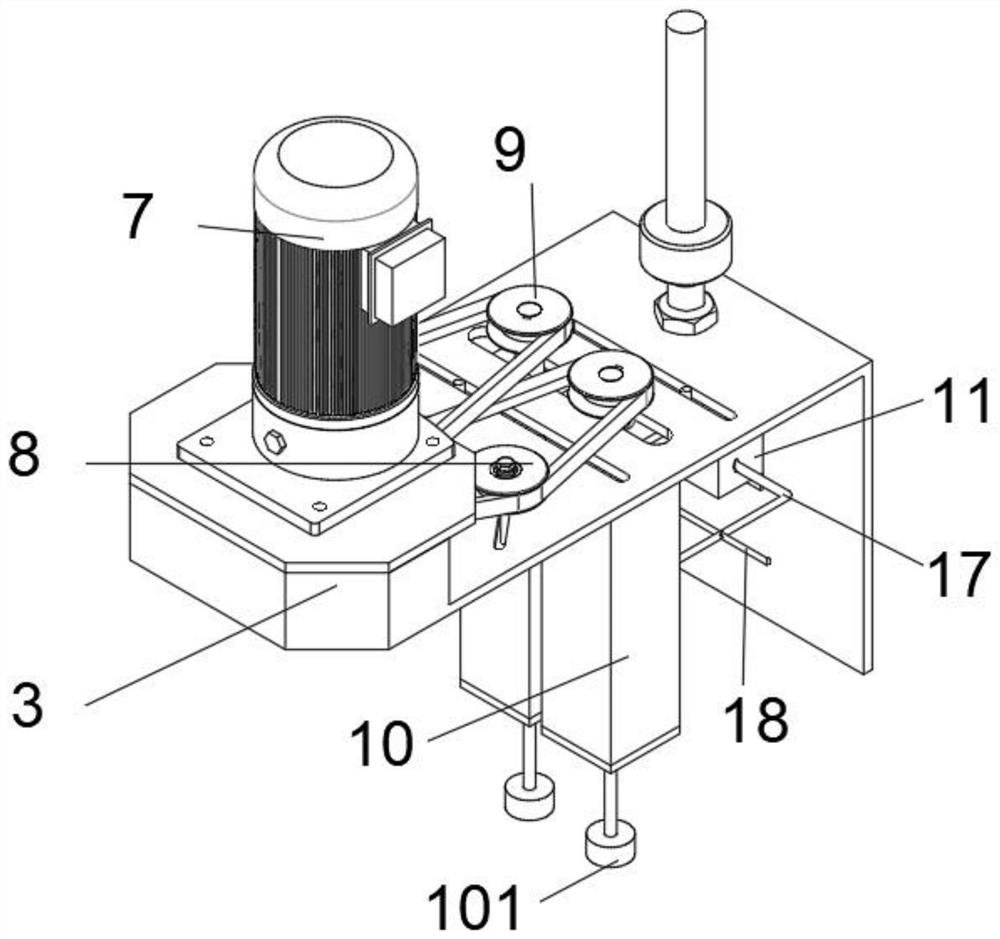

[0033] This embodiment gives a specific structure of a grinding and polishing machine and its polishing process, such as Figure 1-5 As shown, a grinding and polishing machine includes:

[0034]A bottom box 1, the upper surface of which is equipped with a clamping assembly 5 for clamping workpieces, and the front side of the bottom box 1 is provided with a controller 4, and a bracket 2 is welded on one side of the bottom box 1;

[0035] The connecting frame 3 is movably assembled at one side of the bracket 2, and the surface of the bracket 2 is provided with a No.2 cylinder 6, and the piston rod matched with the No.2 cylinder 6 can drive the connecting frame 3 to m

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap