Ceramic tile anti-mite effect testing method

An effect testing, ceramic tile technology, applied in measuring devices, instruments, fluorescence/phosphorescence, etc., to achieve the effect of easy operation, easy observation, and easy repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

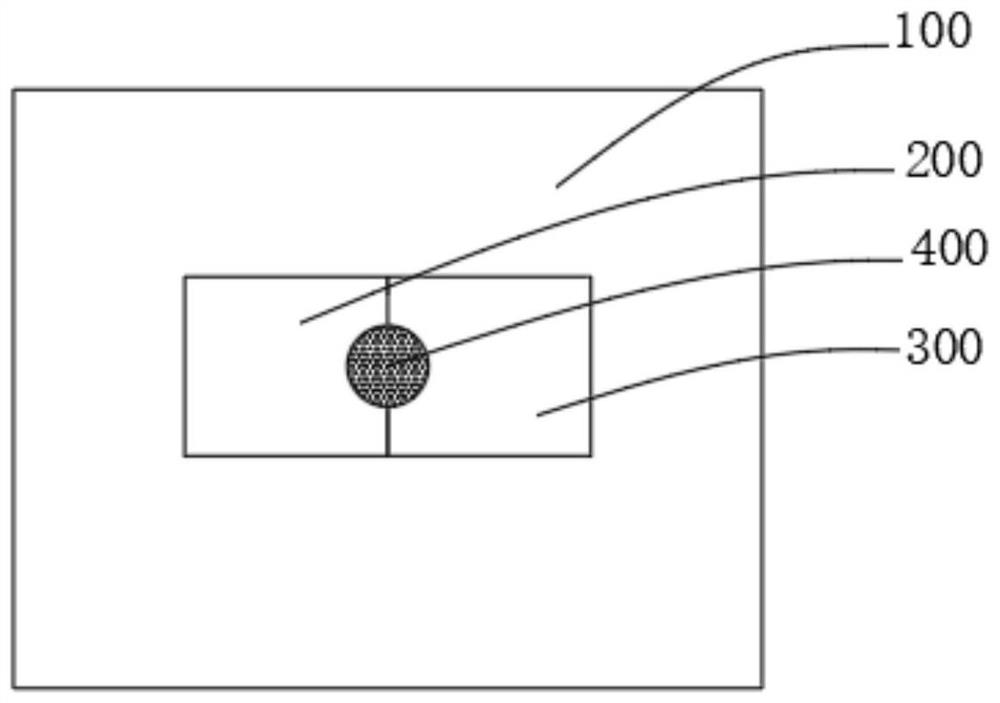

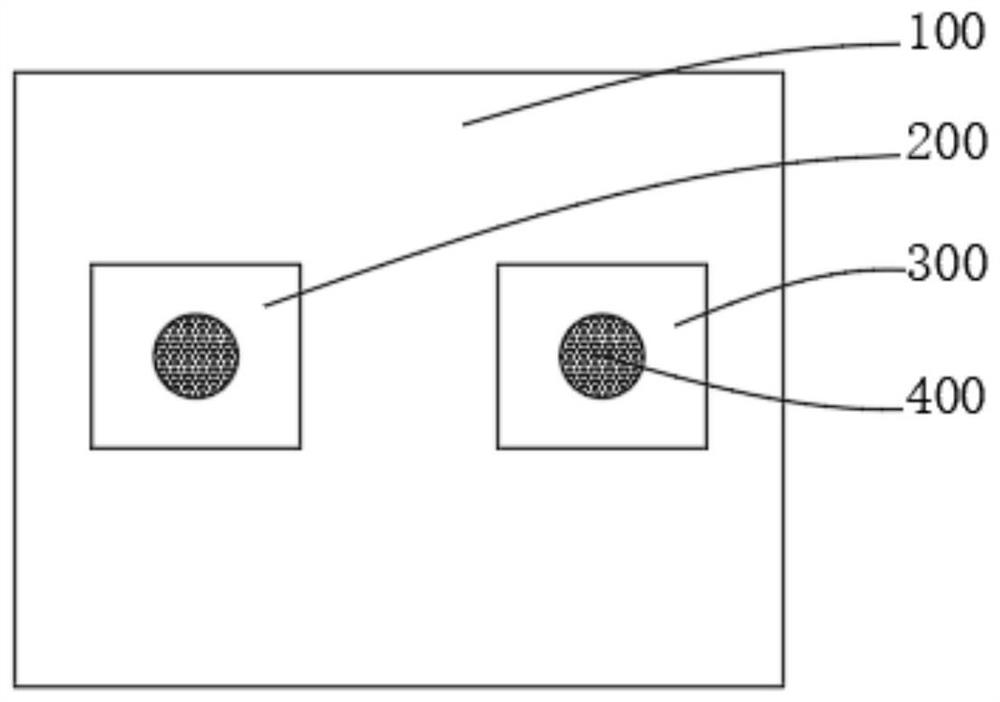

Method used

Image

Examples

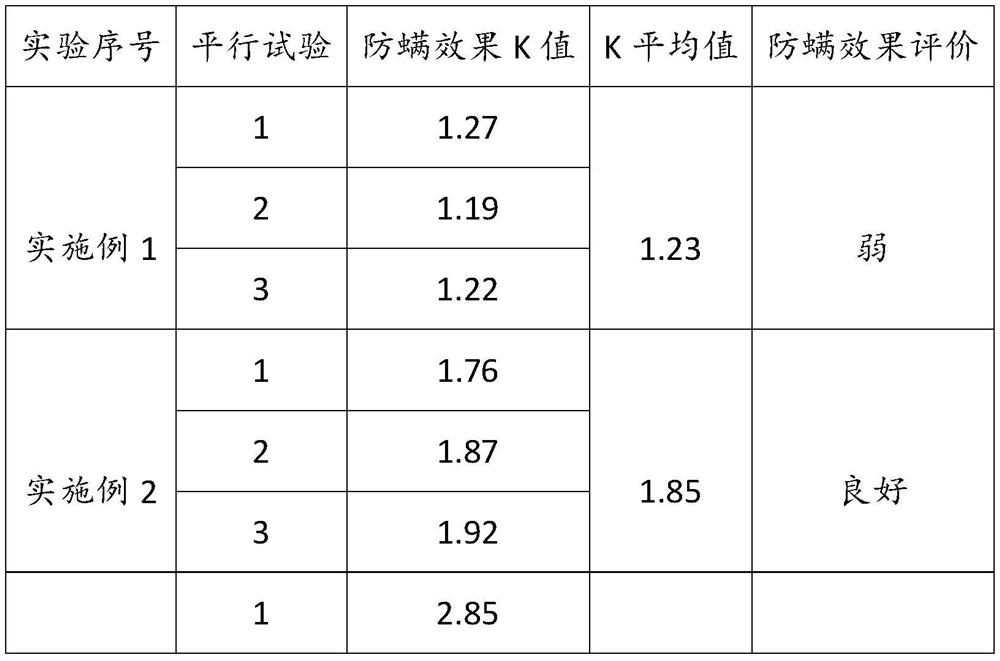

Embodiment 1

[0033] For the samples used, control tile 1: it is a normal polished tile produced on the production line without additional anti-mite function, and the surface has not been modified. Anti-mite tile 1: Anti-mite treatment is carried out on the polished tile without any additional function as the control tile 1. The reagent used is benzyl benzoate, and the load of benzyl benzoate is 0.5 grams per square meter of tile. After standing for 3 days, wait for all Test after the solvent has evaporated. The mites used are 1,000 dust mites, the particle size of the mite feed used is 100 mesh, the fluorescent reagent is 0B-1 green, the thickness of the feed is 2 mm, the color of the control tile 1 and the anti-mite tile 1 is white, and the feeding time is 48 hours .

[0034] Operate according to the tile anti-mite effect test method of the present invention, respectively record the fluorescent area of mite feed before and after the experiment, calculate the anti-mite index K according to

Embodiment 2

[0036] For the samples used, the control tile 2: it is an antique tile that is normally produced on the production line without additional anti-mite function, and the surface has not been modified. Anti-mite tile 2: Anti-mite treatment is carried out on the antique tiles without any additional functions, which are the same as the control tile 2. The reagent used is benzyl benzoate, and 1 g of benzyl benzoate is loaded per square meter of tile. Test after the solvent has evaporated. The mites used were 1000 dust mites, the particle size of the mite feed was 100 mesh, the fluorescent reagent was CBS-351, the thickness of the feed was 2 mm, the color of the control tile 2 and the anti-mite tile 2 was gray, and the feeding time was 48 hours.

[0037] Operate according to the tile anti-mite effect test method of the present invention, respectively record the fluorescent area of mite feed before and after the experiment, calculate the anti-mite index K according to the formula, test

Embodiment 3

[0039] The situation of the samples used, the control tile 3: it is a normal humidity-conditioning tile produced on the production line without additional anti-mite function, and the surface has not been modified. Anti-mite tile 3: Anti-mite treatment is carried out on the same humidity-adjusting tile without any additional function as the control tile 3. The reagent used is benzyl benzoate, and 50 grams of benzyl benzoate is loaded per square meter of tile. After standing for 3 days, wait for Test after all solvents have evaporated. The mites used are 1000 dust mites, the particle size of the mite feed used is 100 mesh, the fluorescent reagent is KSN, the thickness of the feed is 2 mm, the color of the control tile 3 and the anti-mite tile 3 is brown, and the feeding time is 60 hours.

[0040]Operate according to the tile anti-mite effect test method of the present invention, respectively record the fluorescent area of mite feed before and after the experiment, calculate the a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap