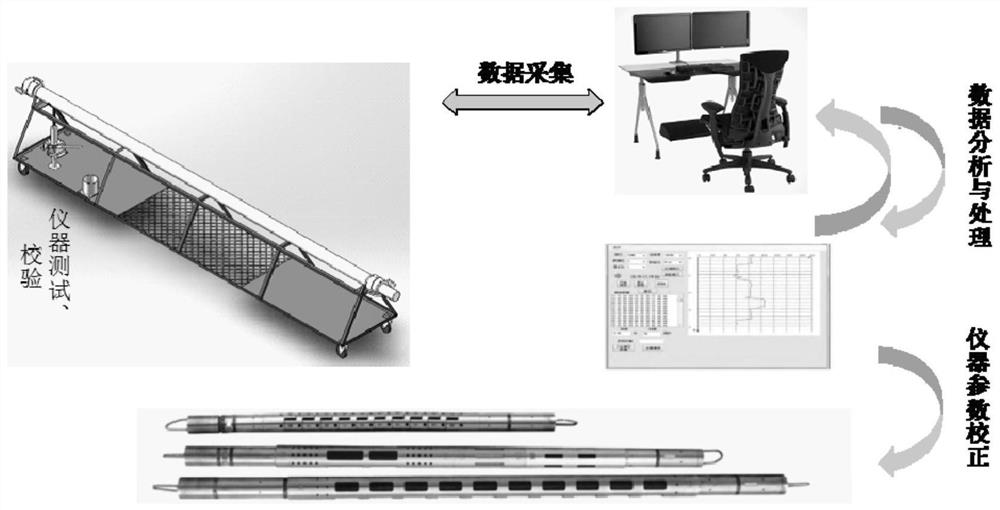

Multipole sub-array sound wave test and calibration device

An array acoustic wave, multipole technology, applied in surveying, wellbore/well components, earth-moving drilling, etc., can solve the problems of expensive, time-consuming receiving transducer calibration, no methods and devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029]The specific scheme of the present invention will be further described below with reference to the accompanying drawings:

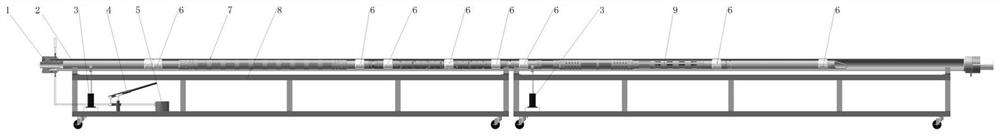

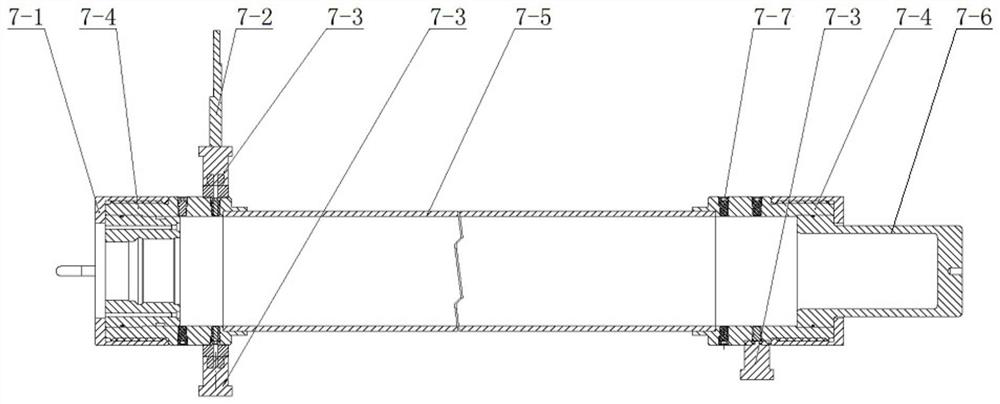

[0030]Such asfigure 2 As shown, a multi-pole array acoustic wave test and a scale device including a formation analog test tub 7, an instrument operation platform 8, a supporter 6, water 2, an acoustic logging instrument 9, a sealing adapter 1, a collection system, Data analysis and processing system;

[0031]The bottom portion of the formation simulation test tub 7 is provided with two instrument operation platform 8, which is disposed in a V-shaped support slot on the instrument operating platform 8, the formation simulation test bucket. 7 is not vertically placed underground, but is supported by the instrument operating platform 8 horizontally, the one sealing adapter 1 is mounted on the acoustic logging instrument 9 by a thread, and eight support The device 6 is fixed to the acoustic logging instrument 9 by a screw and loads the acoustic logging instrument 9 a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap