Warehousing robot

A robot and warehousing technology, applied in the field of warehousing robots, can solve the problems of low utilization rate, high equipment investment and maintenance costs, and achieve the effects of low maintenance costs, small number of motors, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

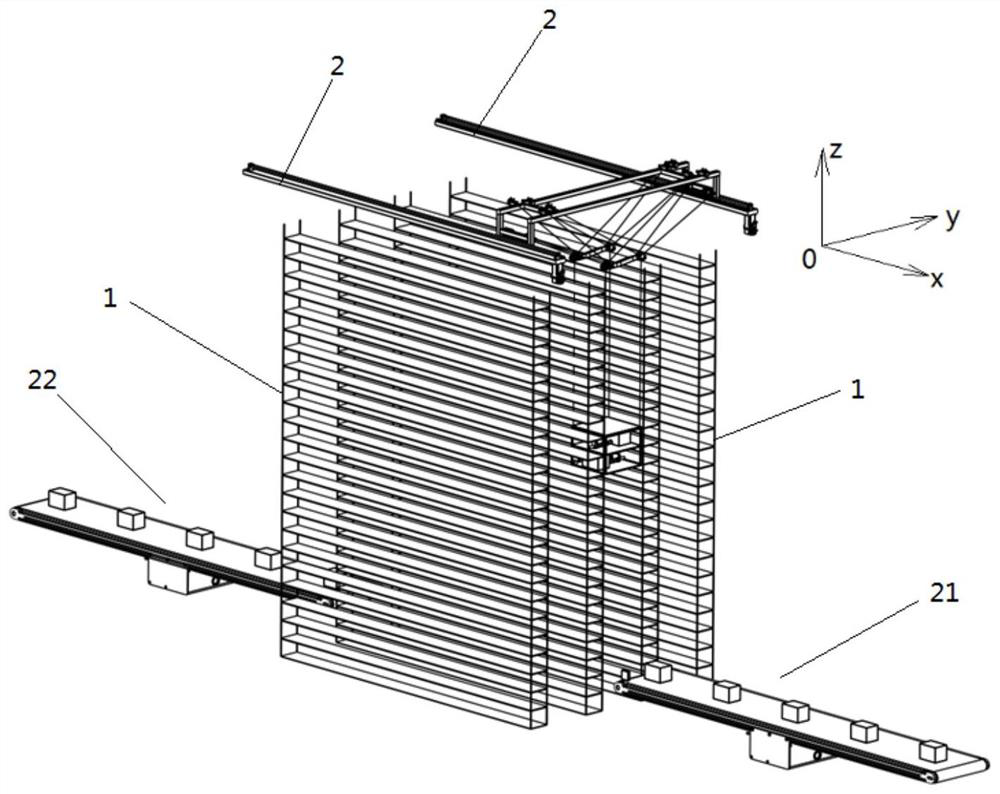

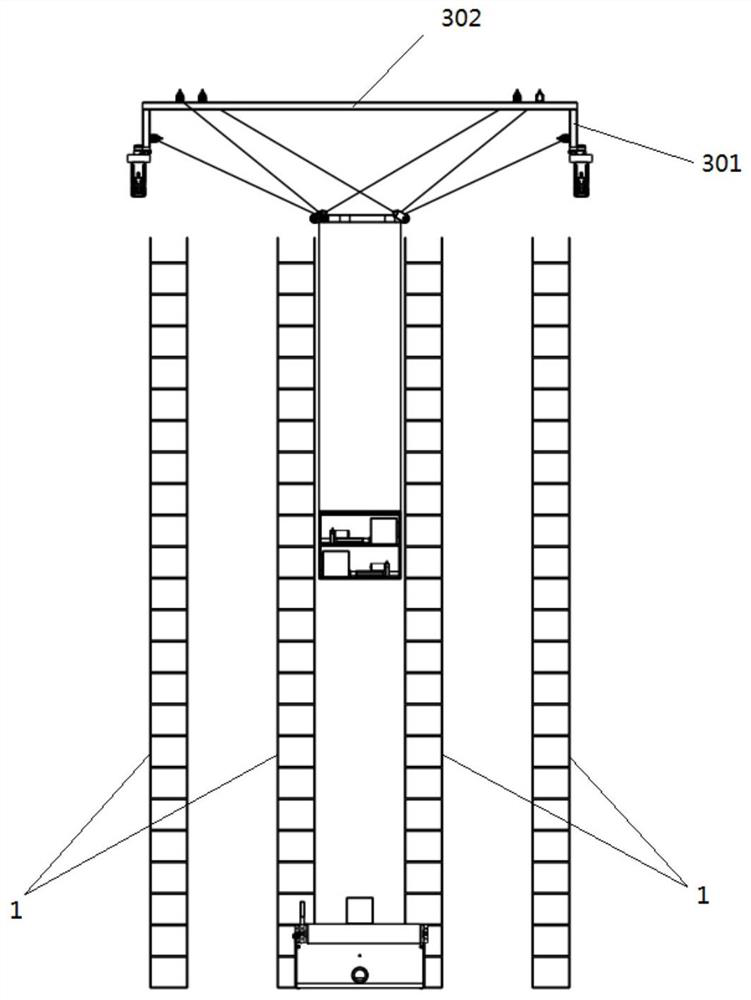

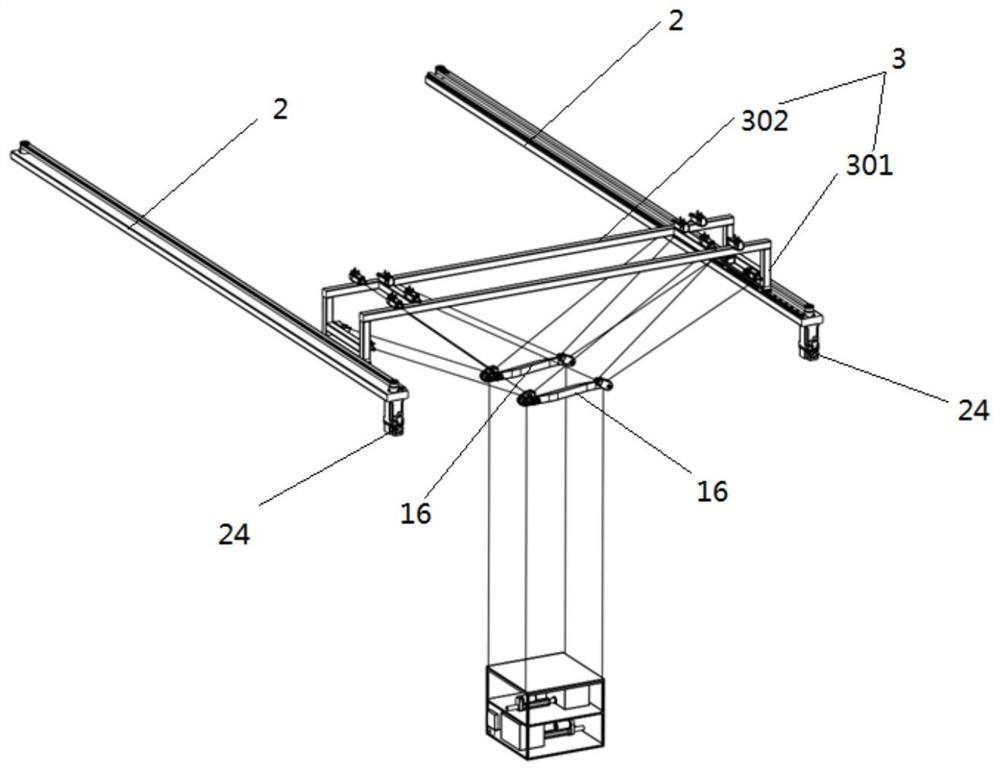

[0031] like figure 1 As shown, the warehousing robot of the present invention is applied in a warehouse, and can cooperate with the goods transfer mechanism 21 and the goods transfer mechanism 22, and can perform warehousing, storage, and warehousing operations on multiple shelves in the warehouse at the same time. Both the goods transfer mechanism 21 and the goods transfer mechanism 22 have conveyor belts for conveying goods, and the number of the conveyor belts is determined by the specific workload.

[0032] The storage robot includes an actuator for loading and unloading goods and a position control mechanism for adjusting the spatial position of the actuator. The actuator is connected to the position control mechanism and is located below the position control mechanism. The position control mechanism is arranged above the shelf 1. The position control mechanism includes an x-axis motion control mechanism, a y-axis motion control mechanism and a z-axis motion control mechanis

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap