Workpiece surface treatment method based on image recognition and shot blasting machine

A technology of workpiece surface and processing method, applied in image data processing, used abrasive processing device, image analysis, etc., can solve the problems of wasting time and lack of machine detection, saving working time and improving the effect of shot blasting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

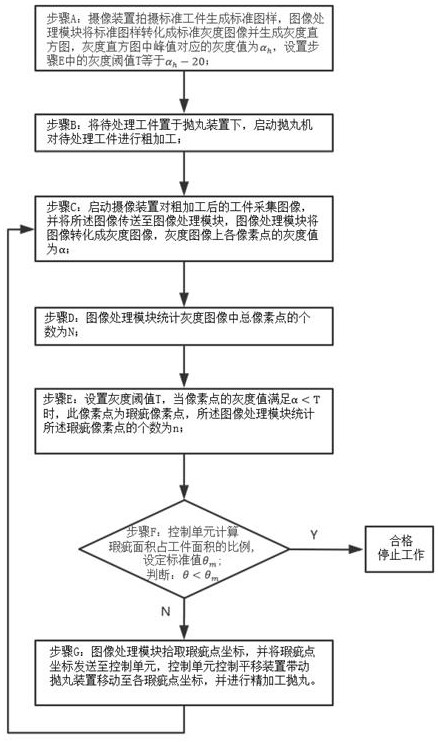

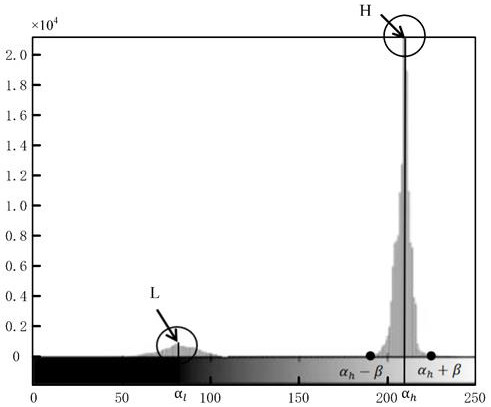

[0040] The invention discloses a workpiece surface treatment method based on image recognition. The method is applied to a shot blasting machine. Decide if secondary processing is required. The oxide skin can be the rust spots on the surface of the metal workpiece, etc. This method can significantly improve the processing effect and efficiency, and the present embodiment will be further described below in conjunction with the accompanying drawings:

[0041] Such as figure 1 As shown, a workpiece surface treatment method based on image recognition, the method is applied to a shot blasting machine, the shot blasting machine includes a shot blasting device, a translation device, a camera device, an image processing module and a control unit;

[0042] The translation device drives the shot blasting device to move on the same horizontal plane;

[0043] The camera device is used to photograph the workpiece and transmit the captured image to the image processing module;

[0044] The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap