Washing device and washing method for rocket engine parts

A technology for a rocket engine and a cleaning device, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as cleaning of rocket engine parts and the surface of easily damaged parts, etc., and achieves convenient maintenance, low cost, reliability and high reliability. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1

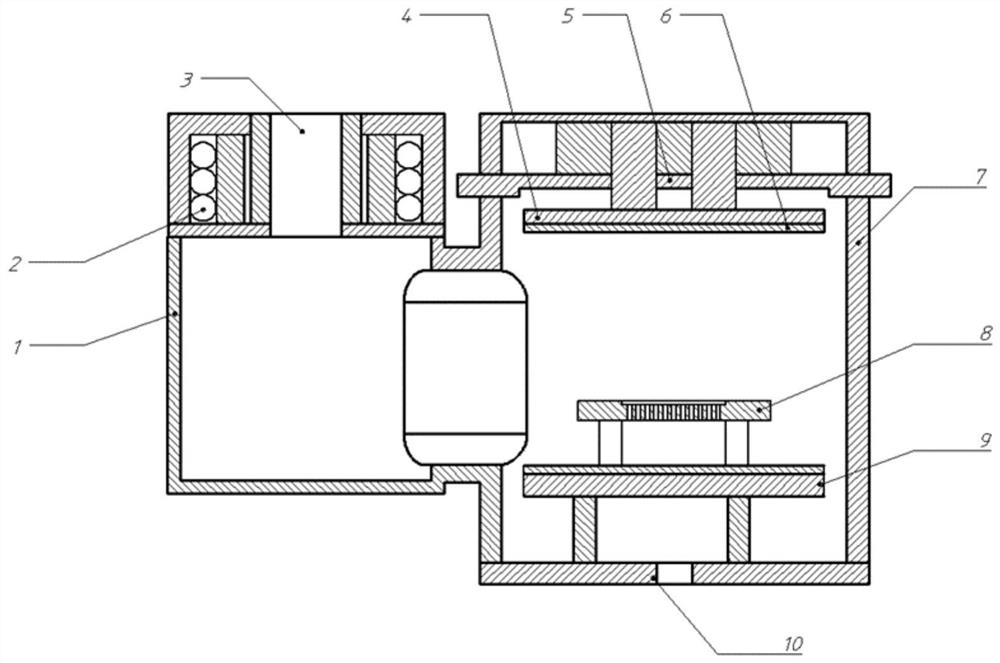

[0033] like figure 1 As shown in a rocket engine parts washing apparatus, comprising a housing for placing the parts to be cleaned, the inner bin for a vacuum environment in the vacuum assembly for washing parts and for plasma cleaning assembly to the tank the reaction gas is pumped into the interior of the reaction gas pump, said casing comprising a main chamber 7 and the secondary communicating chamber 1, the assembly comprises a plasma cleaning chamber disposed in the main chamber 7 for discharging the capacitive coupling a first plate 4 and second plate 9, and disposed in the sub-chamber 1 for the inductive coupling discharge inductor 2, the main chamber and the secondary chamber 7 on the side wall 1 of one of the 3 is provided with an intake port provided on the other side wall outlet port 10, the vacuum assembly is connected to the outlet port 10, the reactive gas is connected to the pump intake port 3. After the parts to be cleaned is placed inside the main

Example Embodiment

[0041] Example 2

[0042] This embodiment is similar to Example 1, except that the front and rear walls of the side walls 7 embodiment the first plate 4 and second plate 9 is provided in the main chamber of the present embodiment. The material of the insulating layer 6 is made of glass, a thickness of 2mm. The inlet and outlet are located on the side wall of the main chamber and the secondary chamber.

Example Embodiment

[0043] Example 3

[0044] This embodiment is similar to Example 1, except in that, in the present embodiment the thickness of the insulating layer in Example 6 was 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap