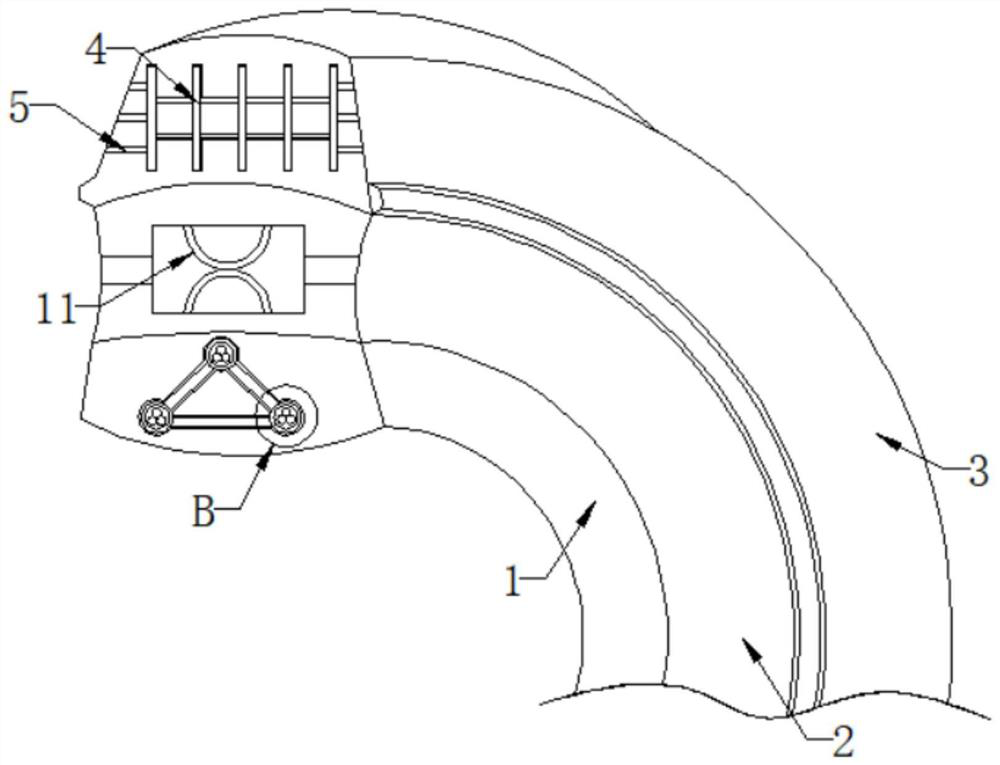

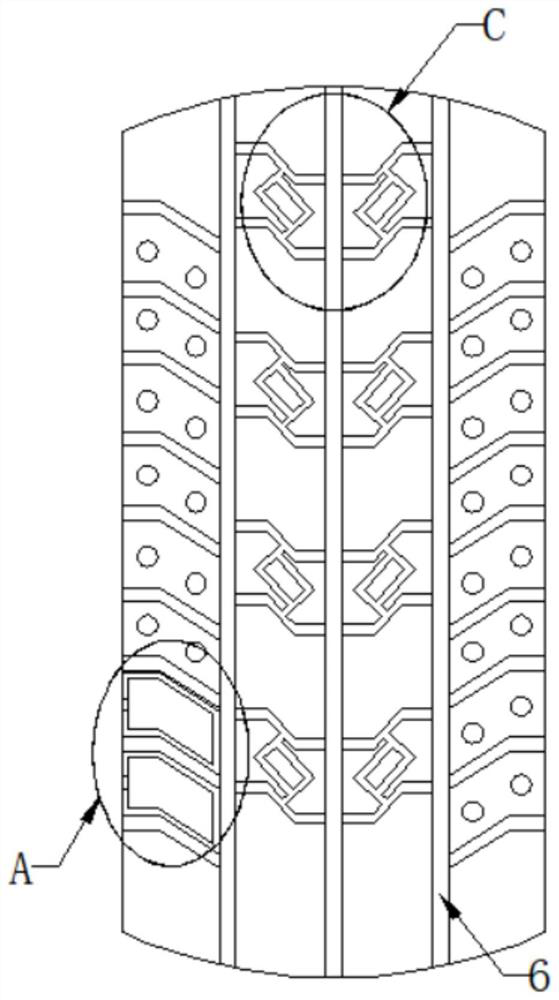

Mine giant solid tire

A solid tire, giant technology, applied in tire measurement, tire parts, non-pneumatic tires, etc., can solve the problems of shortening tire service life, easy to accelerate rubber aging, poor heat dissipation effect, etc., to prolong the use time and accelerate aging. , Enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The specific production and preparation process of the giant solid tire for mine is as follows:

[0037] (1) Production of the base rubber layer: first place a fixing ring and a reinforcing rod inside the mold for producing the base rubber layer, set a reinforcing steel wire inside the fixing ring, and then place rubber raw materials inside the mold. After placing, place the mold on Inside the heating device, adjust the temperature of the heating device to 100 degrees Celsius, and melt the added rubber for 50 minutes until the rubber inside the mold is completely melted;

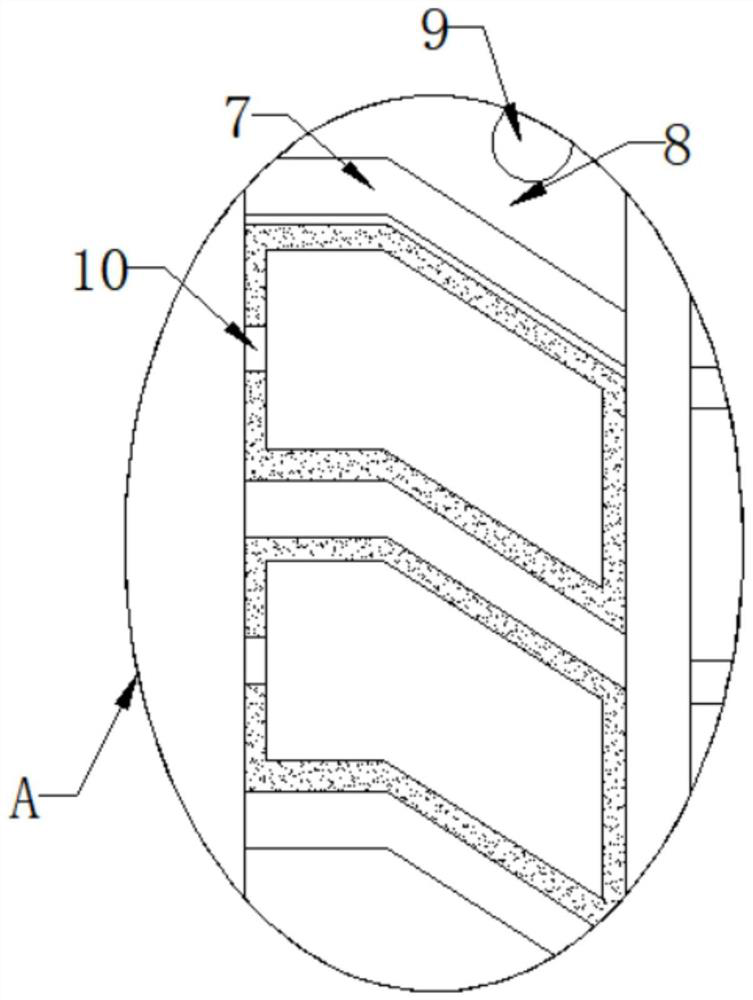

[0038](2) Production of buffer layer: Place rubber raw materials inside the mold for producing buffer layer. After placement, place the mold inside the heating device and adjust the temperature of the heating device to 100 degrees Celsius until the internal rubber material is formed. When the buffer layer is formed Afterwards, a U-shaped buffer ring is arranged inside the buffer layer, and the two parts

Embodiment 2

[0043] The specific production and preparation process of the giant solid tire for mine is as follows:

[0044] (1) Production of the base rubber layer: first place a fixing ring and a reinforcing rod inside the mold for producing the base rubber layer, set a reinforcing steel wire inside the fixing ring, and then place rubber raw materials inside the mold. After placing, place the mold on Inside the heating device, adjust the temperature of the heating device to 125 degrees Celsius, and melt the added rubber for 55 minutes until the rubber inside the mold is completely melted;

[0045] (2) Production of buffer layer: Place rubber raw materials inside the mold for producing buffer layer. After placement, place the mold inside the heating device and adjust the temperature of the heating device to 110 degrees Celsius until the internal rubber material is formed. When the buffer layer is formed Afterwards, a U-shaped buffer ring is arranged inside the buffer layer, and the two parts

Embodiment 3

[0050] The specific production and preparation process of the giant solid tire for mine is as follows:

[0051] (1) Production of the base rubber layer: first place a fixing ring and a reinforcing rod inside the mold for producing the base rubber layer, set a reinforcing steel wire inside the fixing ring, and then place rubber raw materials inside the mold. After placing, place the mold on Inside the heating device, adjust the temperature of the heating device to 150 degrees Celsius, and melt the added rubber for 60 minutes until the rubber inside the mold is completely melted;

[0052] (2) Production of buffer layer: Place rubber raw materials inside the mold for producing buffer layer. After placement, place the mold inside the heating device and adjust the temperature of the heating device to 120 degrees Celsius until the internal rubber material is formed. When the buffer layer is formed Afterwards, a U-shaped buffer ring is arranged inside the buffer layer, and the two parts

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap