Movable trolley for bridge guardrail formwork assembly and disassembly and construction method thereof

A mobile guardrail technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of inconvenient continuous operation, heavy safety factor, etc., and achieve the effect of shortening installation and dismantling time, increasing working area, and accurate formwork installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

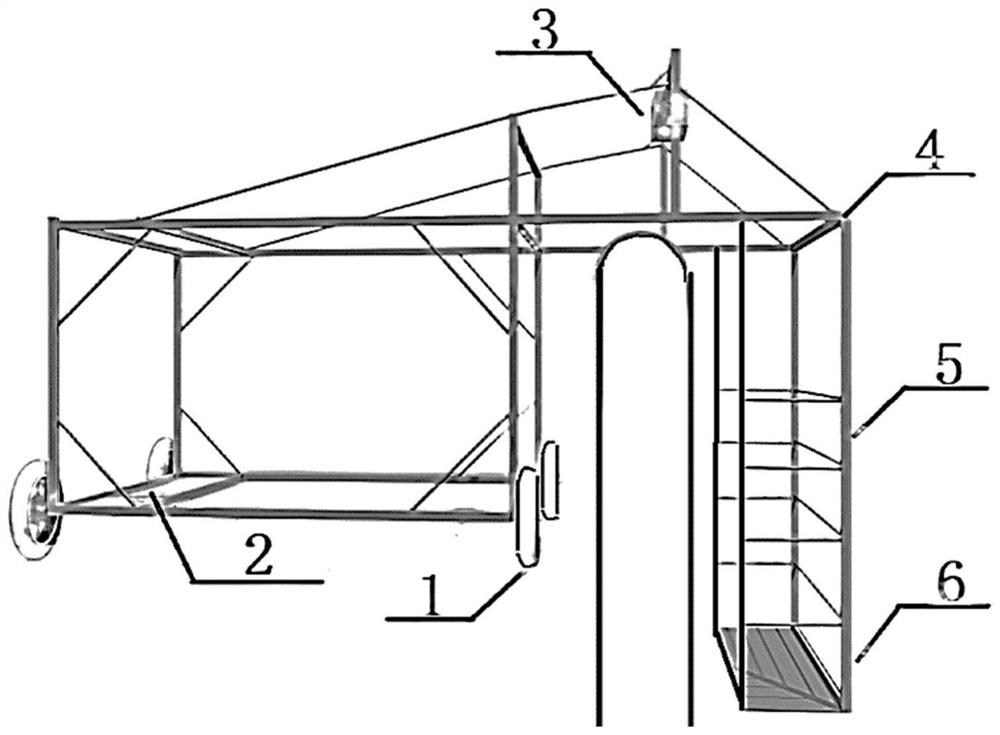

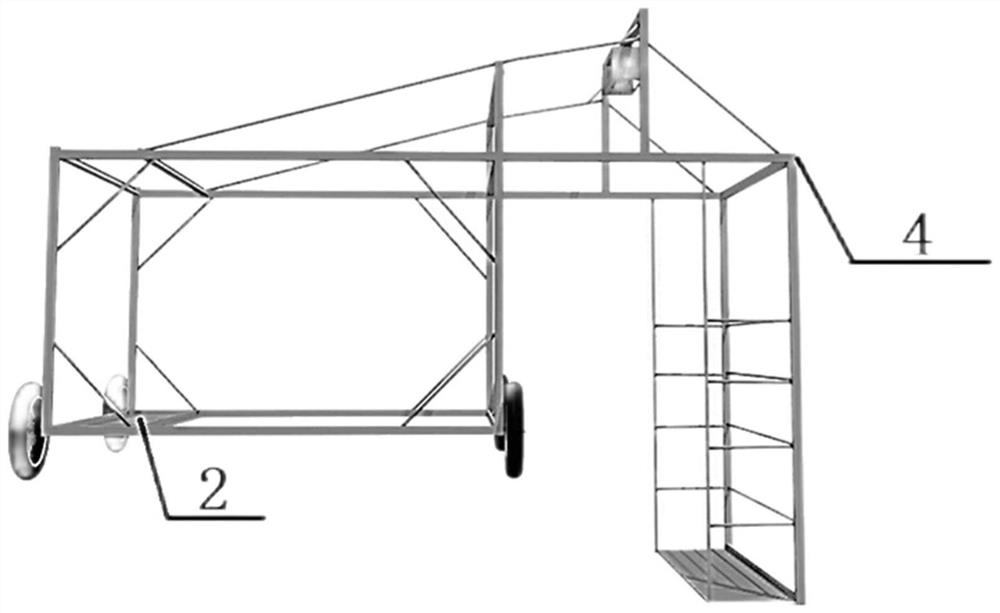

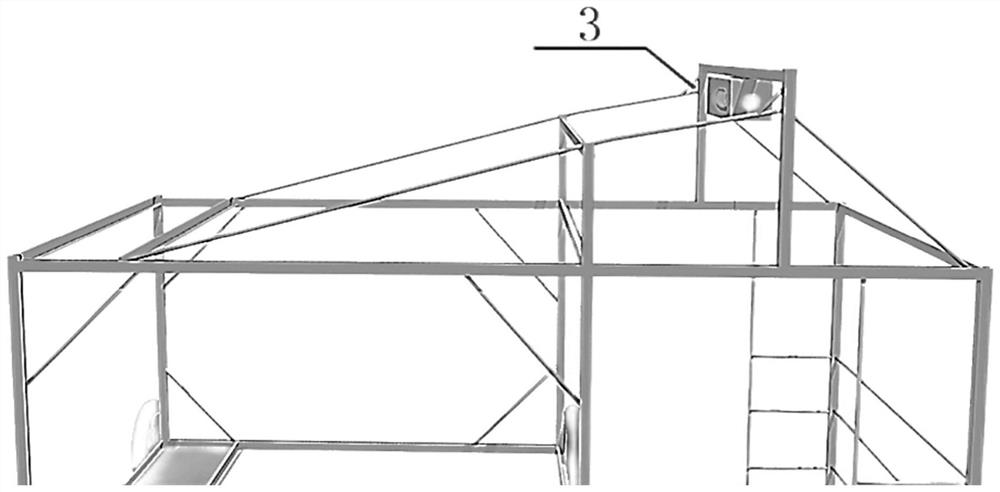

[0036] see figure 1 The bridge guardrail template installation and disassembly mobile trolley of the present invention includes tire-type walking chassis 1 and hanging basket 6 respectively arranged on both sides of the guardrail template to be installed and dismantled. The tire-type walking chassis 1 is provided with a cargo platform 2, and the cargo platform 2 is connected to the horizontally arranged cantilever beam 4 through the first bracket, and the hanging basket 6 is also connected to the cantilever beam 4 through the second bracket. The tire-type walking chassis 1 includes a rectangular bearing bracket and four running parts, and the rectangular bearing bracket is installed between the four running parts. The first bracket is a cube frame whose four corners of the bottom surface are connected to the rectangular bearing bracket, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap