Bidirectional variable-curvature variable-friction pendulum type tuned mass damper

A technology of tuning mass damping and variable curvature, which is applied in the direction of protective buildings/shelters, building types, buildings, etc., and can solve the problems that friction pendulum TMD cannot effectively absorb energy, reduce energy consumption efficiency of friction pendulum TMD, and structure Space utilization rate and benefit reduction and other issues, to achieve excellent two-way shock absorption and energy consumption effect, stable and continuous self-adaptive effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

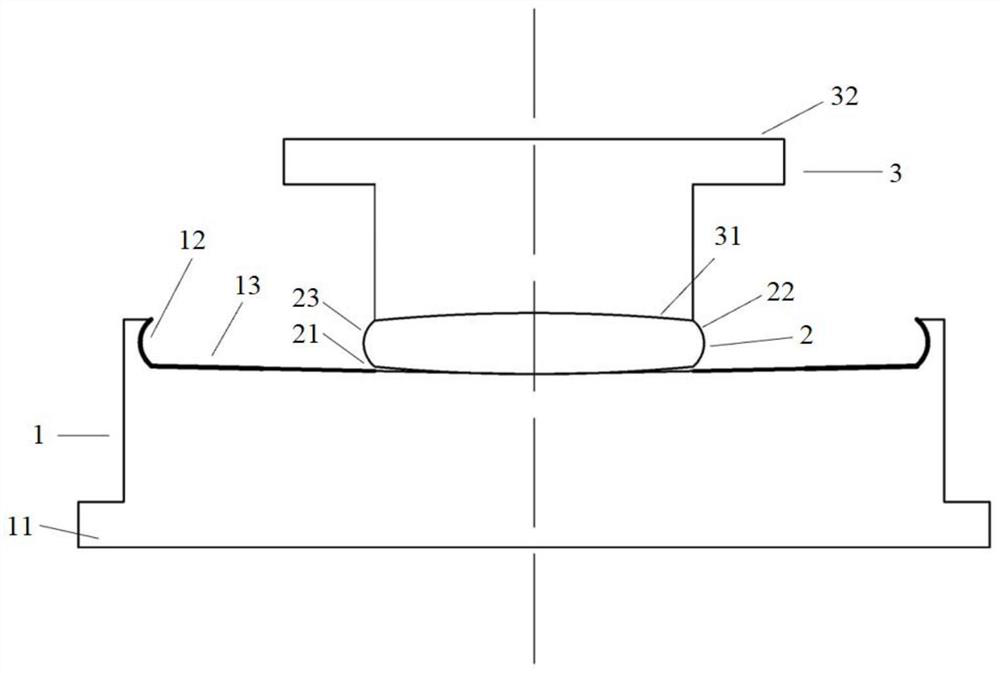

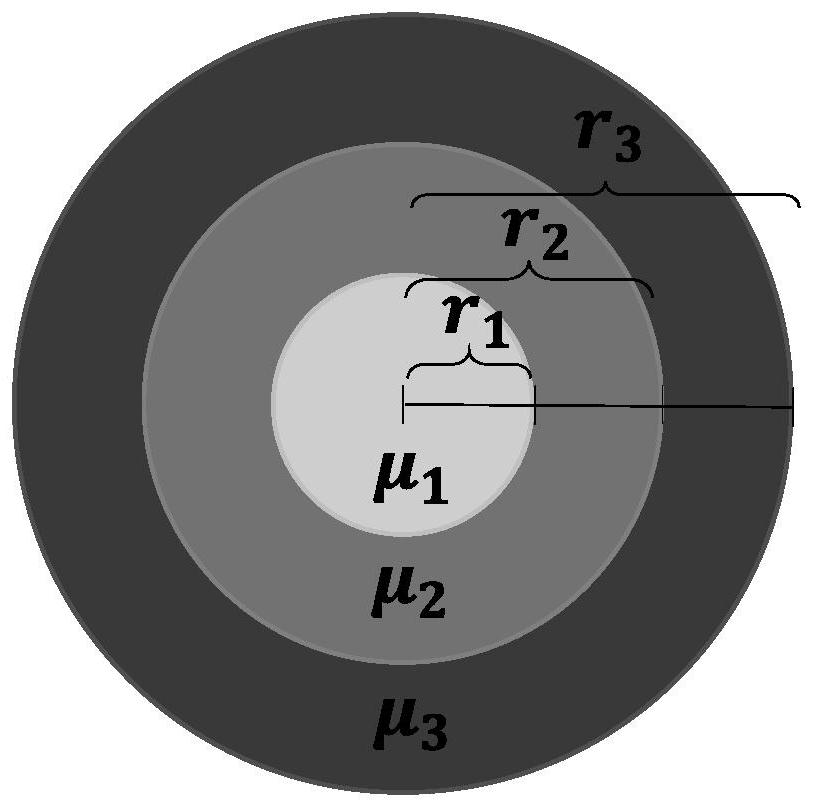

[0030] combine Figure 1 to Figure 3 As shown, this embodiment provides a support seat plate 1 for a two-way variable curvature variable friction pendulum tuned mass damper. Adaptive contact surface, the contact surface is a concave arc surface, on the contact surface from bottom to top, there are a plurality of smoothly connected spherical concave surfaces, a friction layer is provided on each spherical concave surface, and the radius of the multiple spherical concave surfaces is from The coefficients of friction decrease sequentially from bottom to top, and the friction coefficients of the friction layers of multiple spherical concave surfaces increase sequentially from bottom to top.

[0031] The upper surface 13 of the support seat plate 1 is used to contact the lower sliding surface 21 of the slider 2 (ie, the lower surface of the slider 2); figure 1 As shown, in this embodiment, the contact surface of the upper surface 11 of the support seat plate 1 is a concave arc surfac

Embodiment 2

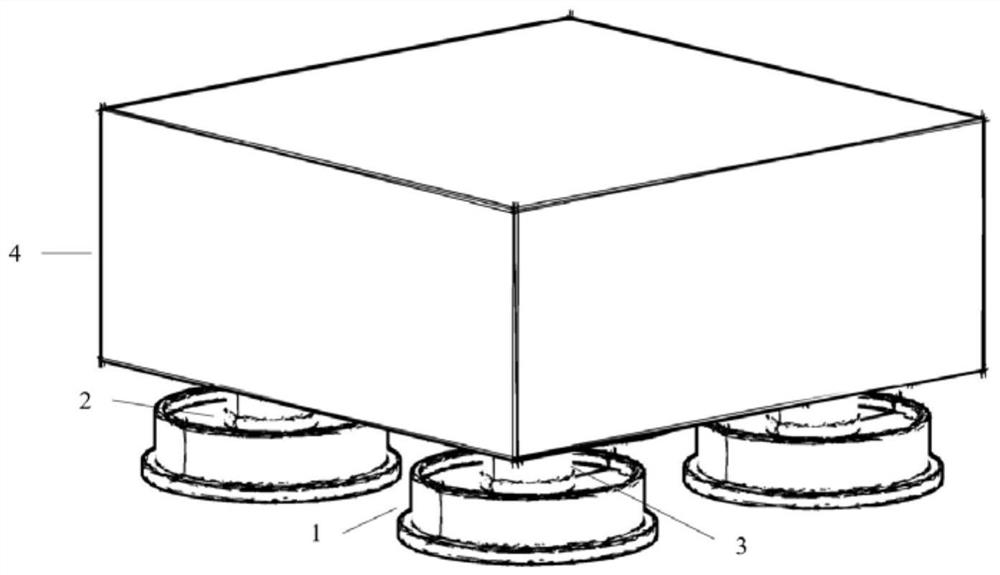

[0042] combine Figure 1 to Figure 3 As shown, this embodiment provides a two-way variable curvature and variable friction pendulum tuned mass damper, including an inertial mass 4 and at least one support set, each support set includes a support member 3, a slider 2 and the first embodiment. The base plate 1 is supported, the connecting support member 3 is arranged below the inertial mass block 4 , the upper part of the slider 2 is connected with the connecting support member 3 , and the lower surface of the slider 2 is contacted and connected with the contact surface of the supporting base plate 1 .

[0043] In this embodiment, there is no strict limit on the number of sets of supporting sets, and one inertial mass 4 can be equipped with multiple matching supporting sets of the same type according to the actual situation.

[0044] The connecting support member 3 is located under the inertial mass 4, and can be fixedly connected to the inertial mass 4 through detachable connector

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap