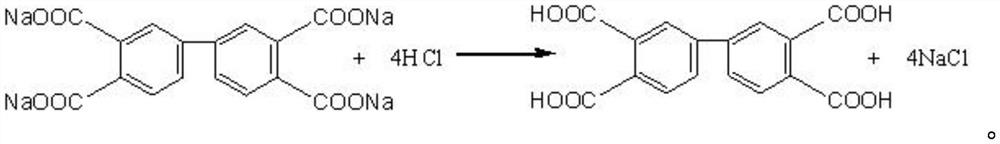

3, 3 ', 4, 4'-biphenyltetracarboxylic acid reaction crystallization method

A technology of biphenyltetracarboxylic acid and sodium biphenyltetracarboxylic acid is applied in the separation/purification of carboxylic acid compounds, the preparation of carboxylate, organic chemistry, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 300Kg of pure water and 40Kg of 30wt% industrial hydrochloric acid to the enamel reaction tank, heat up to 85°C, and dropwise add 70°C 3,3',4,4'-sodium biphenyltetracarboxylate reaction solution, 300L / h according to 568L / h h Add 40 ℃, 30wt% hydrochloric acid solution dropwise, and control the reaction temperature to 85 ℃, after 2 hours of dropwise addition, transfer the reaction solution to a cooling enamel reaction tank according to the starting 868L / h, cool down to 55 ℃, use a centrifuge for solidification The 3,3',4,4'-biphenyltetracarboxylic acid flake crystals obtained by liquid separation and centrifugation have a moisture content of 15 wt %, and the measured content after drying is 99.8 wt %.

Embodiment 2

[0052] Add 310Kg of pure water and 42Kg of 30wt% industrial hydrochloric acid to the enamel reaction tank, heat up to 80°C, and dropwise add 70°C 3,3',4,4'-sodium biphenyltetracarboxylate reaction solution, 290L / h according to 570L / h h Add 40 ℃, 30wt% hydrochloric acid solution dropwise, and control the reaction temperature to 80 ℃, after 2 hours of dropwise addition, transfer the reaction solution to a cooling enamel reaction tank according to the starting 860L / h, cool down to 50 ℃, use a centrifuge for solidification The 3,3',4,4'-biphenyltetracarboxylic acid flake crystals obtained by liquid separation and centrifugation have a moisture content of 17 wt %, and the measured content after drying is 99.7 wt %.

Embodiment 3

[0054] Add 290Kg of pure water and 35Kg of 30wt% industrial hydrochloric acid to the enamel reaction tank, heat up to 82°C, and dropwise add 70°C 3,3',4,4'-sodium biphenyltetracarboxylate reaction solution, 295L / h according to 565L / h h Add 40 ℃ 30wt% hydrochloric acid solution dropwise, and control the reaction temperature to 82 ℃, after 2 hours of dropwise addition, transfer the reaction solution to a cooling enamel reaction tank according to the starting 860L / h, cool down to 52 ℃, use a centrifuge to conduct solid-liquid separation and centrifugation to obtain 3,3',4,4'-biphenyltetracarboxylic acid flake crystals (crystal morphology such as figure 1 shown), the moisture content was 13 wt%, and the measured content after drying was 99.6 wt%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap