Microstep spot-welding method and equipment

A welding method and welding equipment technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., to achieve the effect of avoiding fabric wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The micro-step spot welding method and equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

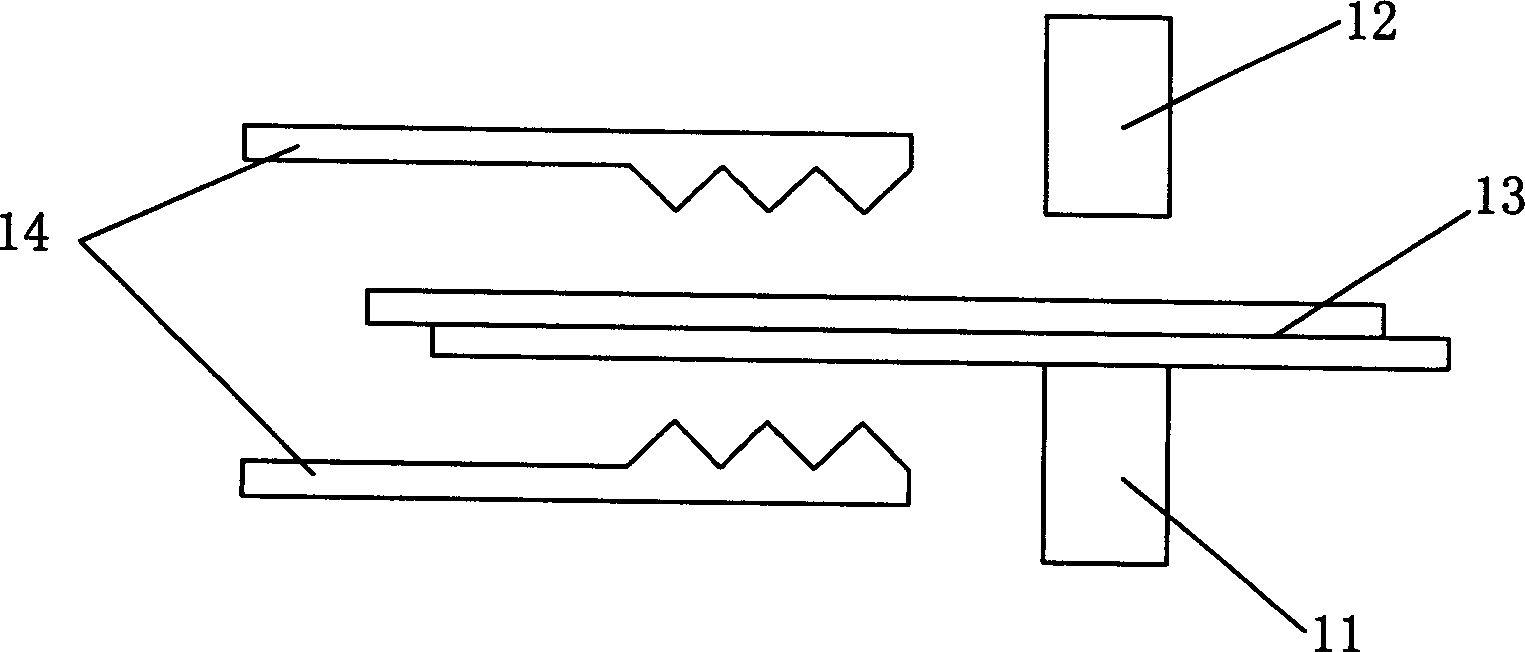

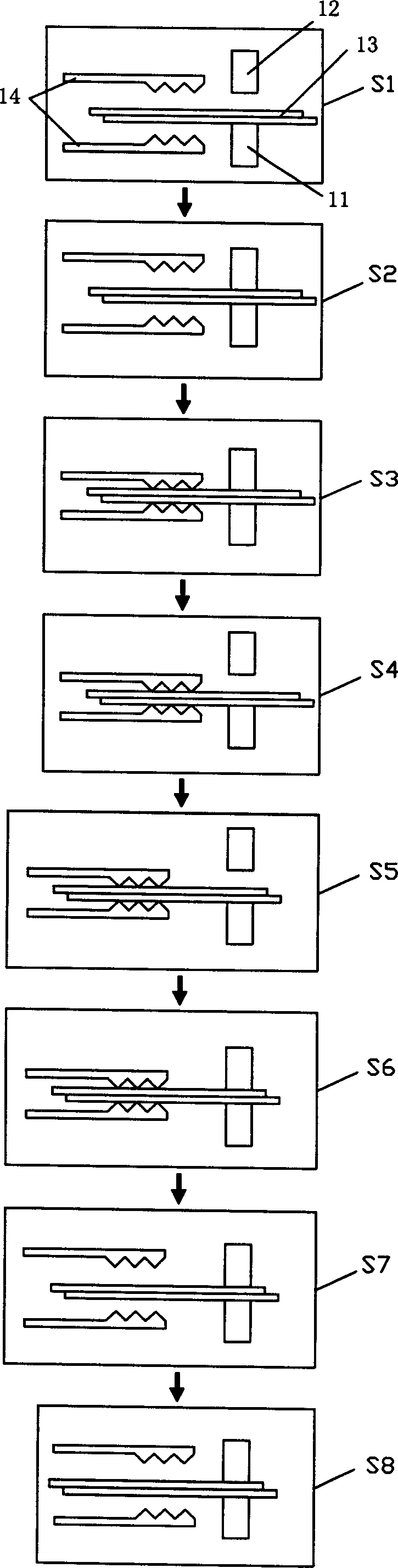

[0028] see figure 1 The micro-step spot welding equipment of the present invention includes an energy generator (not shown), a fixed shock head 11 connected to the energy generator to generate vibration, a movable pressure nozzle 12 arranged opposite to the fixed shock head 11, and a driven The pile of cloth to be welded 13 and the moving conveyor 14 . In this embodiment, the energy generator is an ultrasonic energy generator; it can be understood that the energy generator can also be a high-frequency energy generator or other forms of high-frequency heaters. Turn on the energy generator, so that the fixed shock head 11 connected to it generates ultrasonic vibrations to generate heat, thereby heating the cloth pile 13 . The shape of the fixed vibration head 11 and the pressure nozzle 12 match, and can be desi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap