Simple box-type glass packing frame

A packaging rack and box-type technology, which is applied in the packaging field of flat materials, can solve the problems of large financial resources, material resources and time, does not conform to national industrial policies, and increases product costs, so as to save product costs, simple structure, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

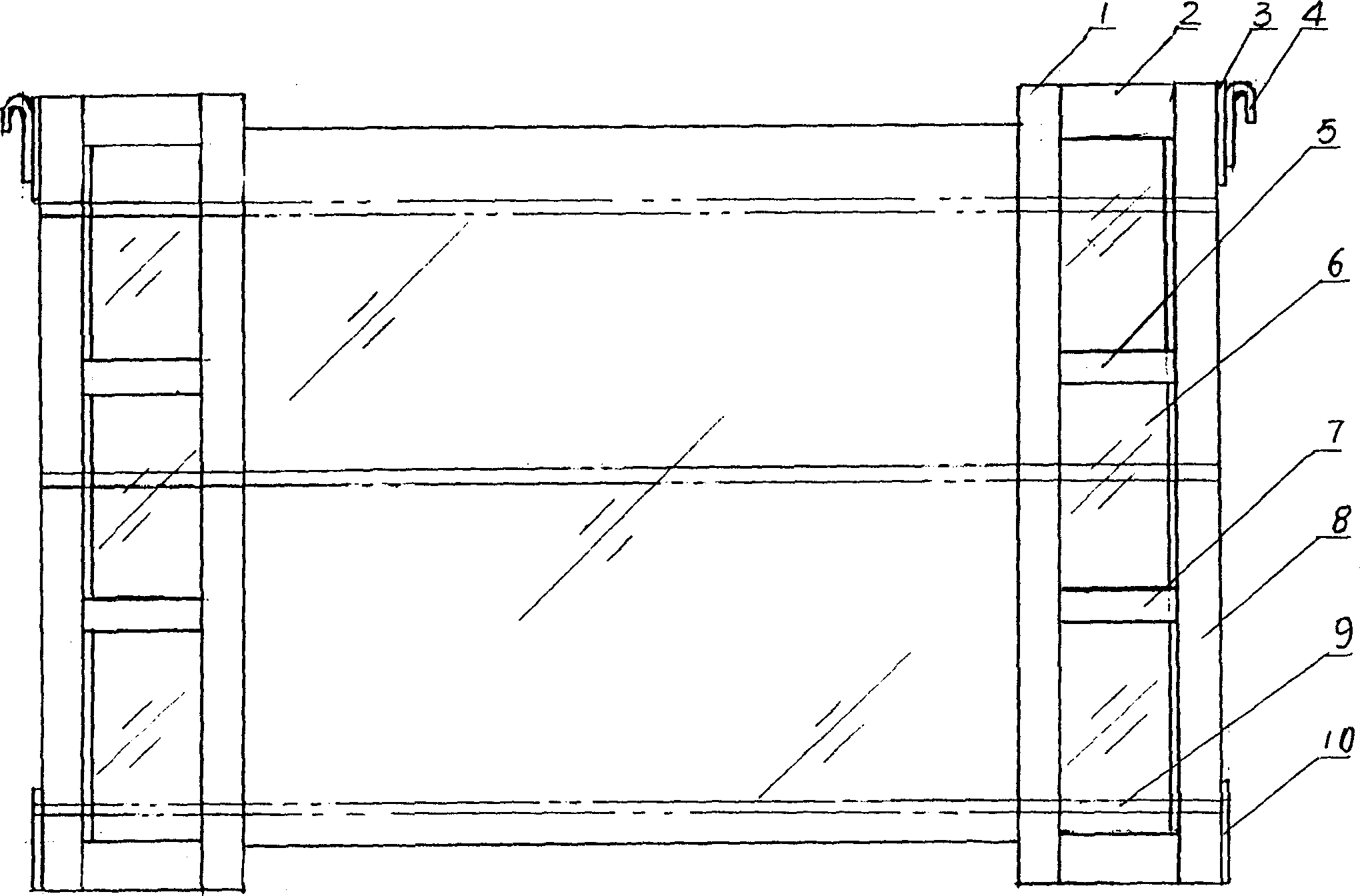

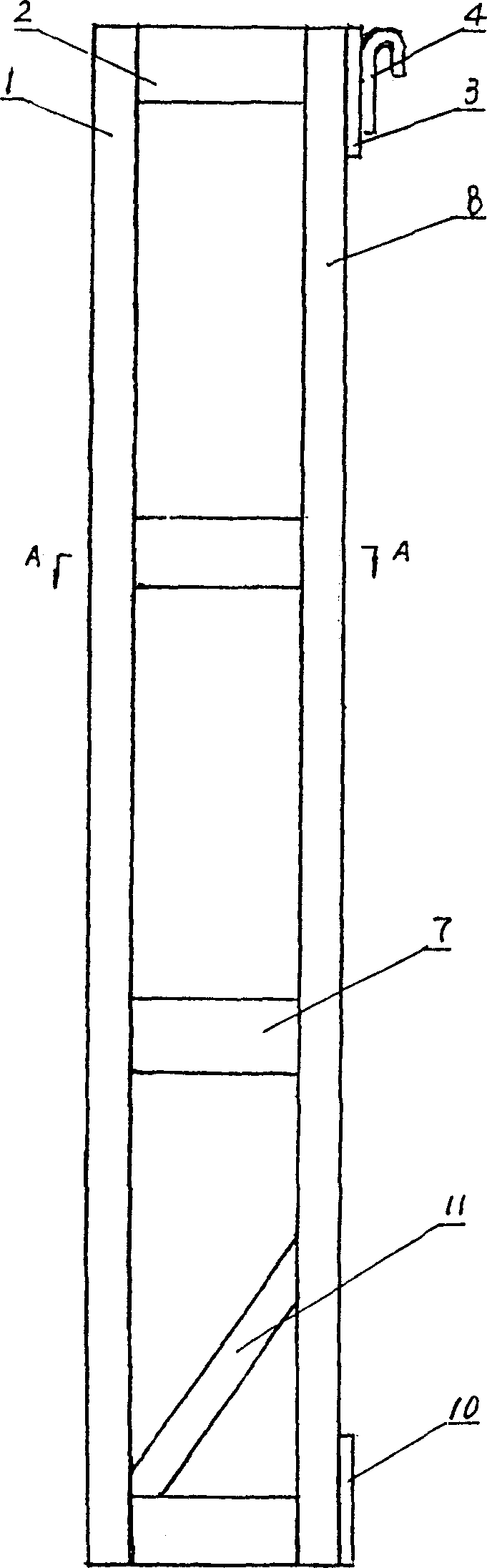

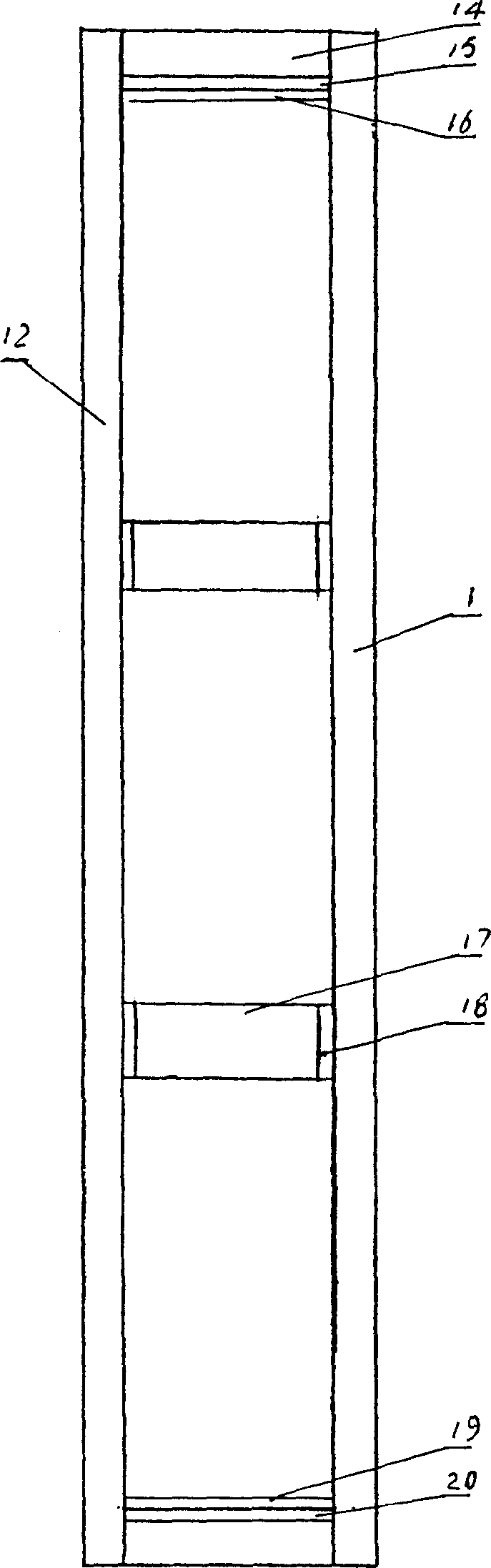

[0012] Refer to attached Figure 1~4 , the simple box-type glass packaging frame structure is composed of two profile packaging frames, each profile packaging frame includes four columns 1, 8, 12, 13, several cross bars 2, 5, 7, 11, 14, 17, reinforcement Plates 3,10, hooks 4, end plates 15,20. Several crosspieces are installed between the four columns, and upper end plates 15 and lower end plates 20 are respectively installed at the upper and lower ends of the columns, thereby forming a box-type structure with one side opening, which is convenient for clamping glass plates 6, and on the outer side of the upper part of the profile packaging rack. Reinforcing plates 3, 10 are welded up and down on columns 8, 13, and hanging hooks 4 are housed on the upper reinforcing plate 3. Soft cushioning material 18 is housed in crosspiece 2,5,7,11,14,17 inboard, in order to protect glass or other packed plates. The upper end plate 15 and the lower end plate 20 can be respectively provided wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap