Cold, hot food insulation box

A technology for hot food and heat preservation boxes, which is applied in heat preservation containers, household refrigeration devices, lighting and heating equipment, etc. It can solve the problems of reduced box capacity, difficulty in tightly connecting the box body with the box cover, and lack of heat preservation temperature. , to achieve the effect of improving the overall bearing capacity, facilitating long-distance transportation, and facilitating short-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

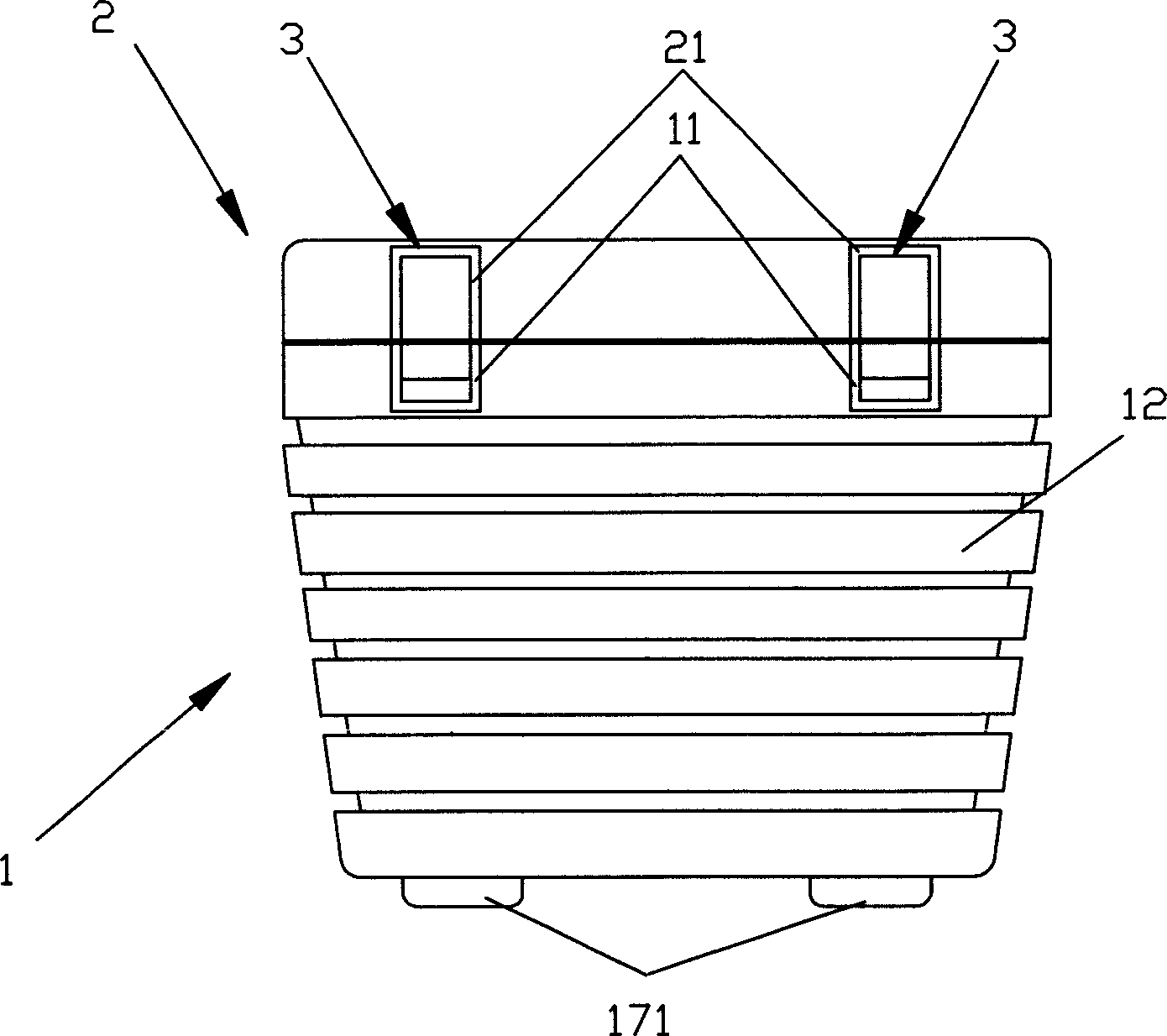

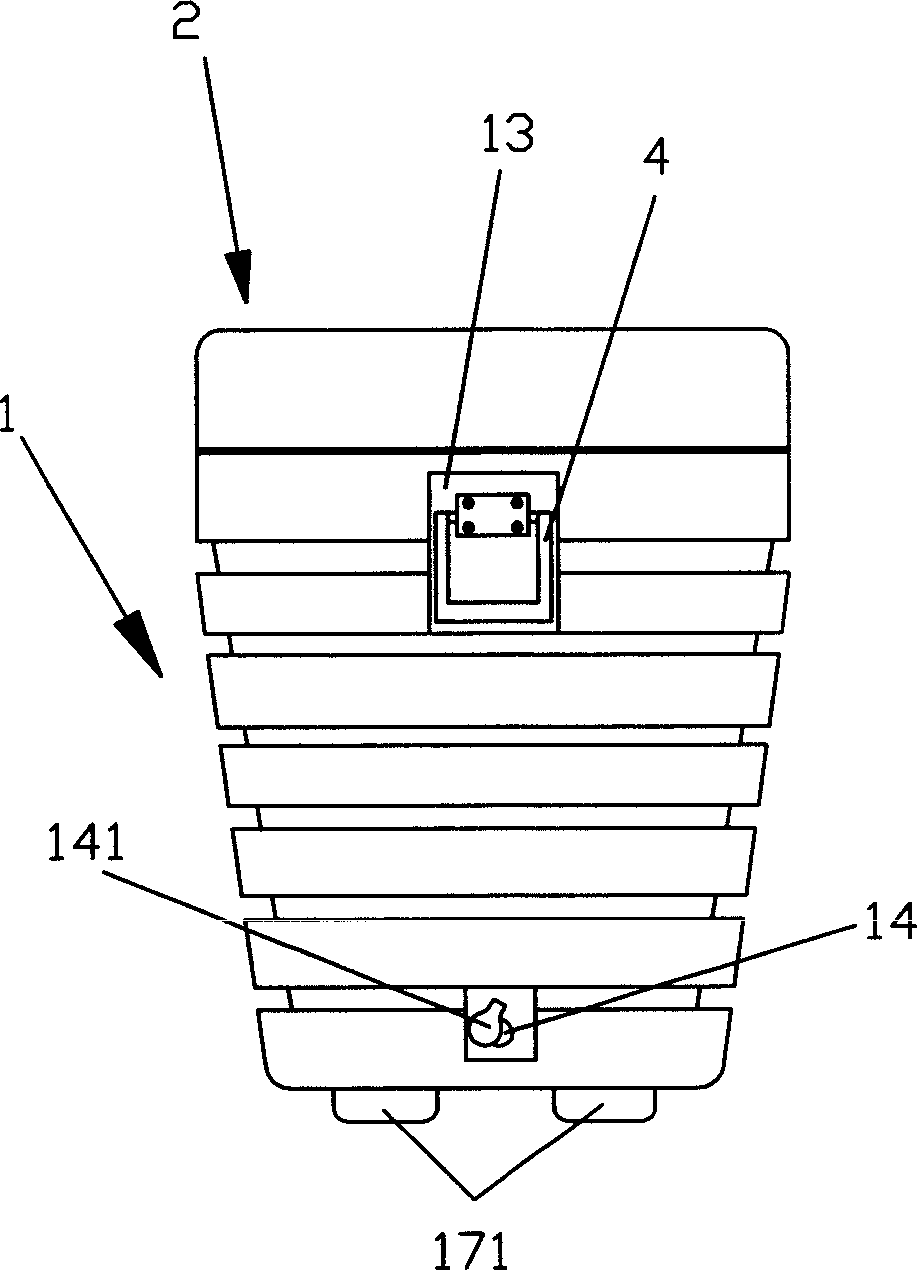

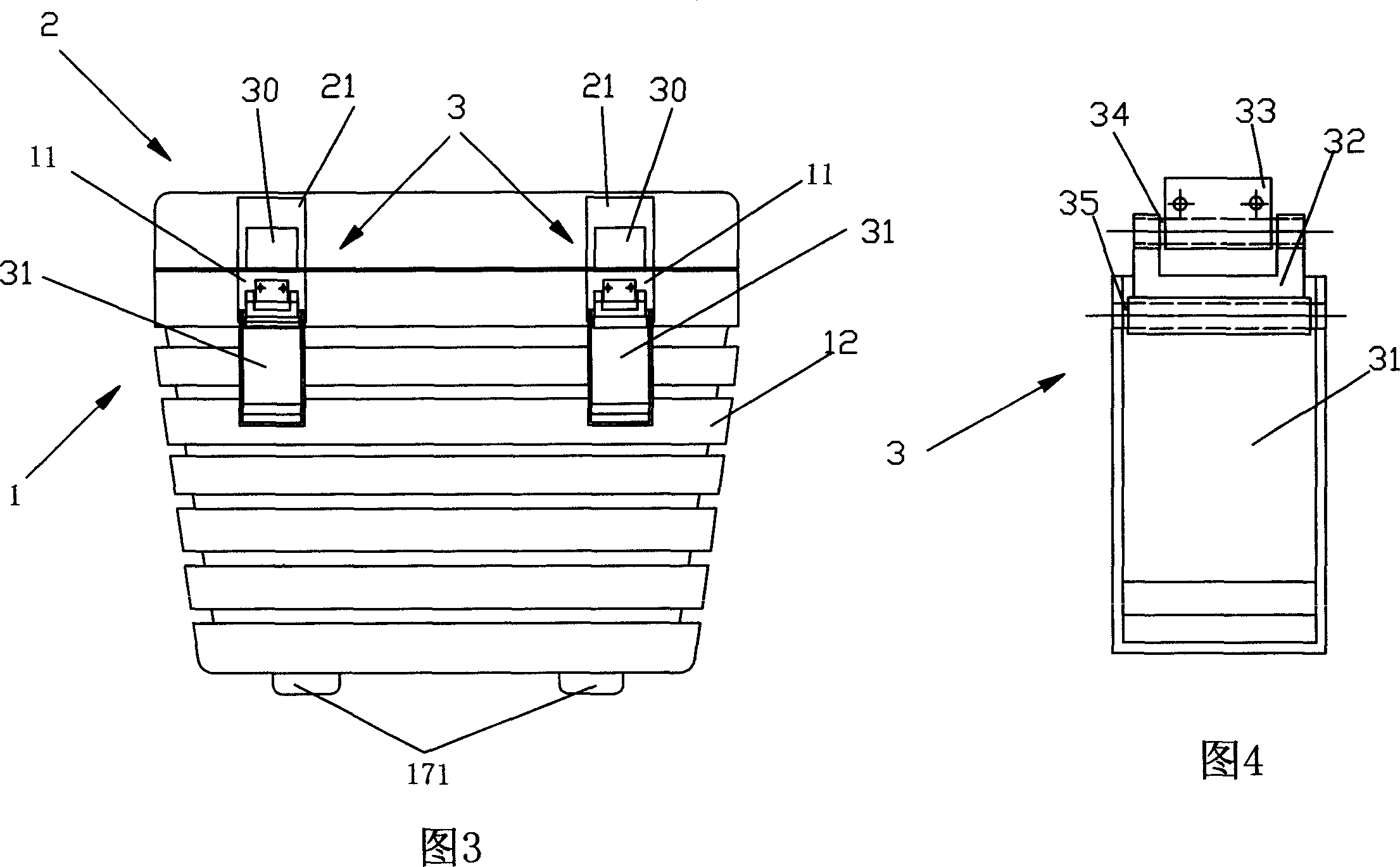

[0033] See figure 1 , with reference to Figure 5 , 6 , 7, 8, a cold and hot food insulation box shown in the figure is made of food-grade ABS plastic, including a box body 1 and a box cover 2 with a hollow structure, and the cavity of the hollow structure is filled with high Molecular foam insulation material, the inner surface 2b of the box cover 2 is provided with a sealing groove 24 corresponding to the surface around the top 15 of the box body 1, and a rubber sealing strip is embedded in the sealing groove 24, and the sealing groove 24 A sealing boss 25 higher than the inner surface 2b of the box cover is also provided around the inner side, and the peripheral size of the sealing boss 25 matches the size of the opening of the box inner cavity 16 .

[0034] Such as Figure 5 , 9 As shown, the upper surface 2 a of the box cover 2 is provided with a limiting groove 22 , and the bottom 17 of the box body 1 corresponding thereto is provided with a limiting boss 171 . The com

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap