Staple detecting mechanism of electric stapler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0036] In the following, one embodiment of the staple sheet-detecting mechanism of the electric stapler according to the present invention will be explained with reference to the drawings.

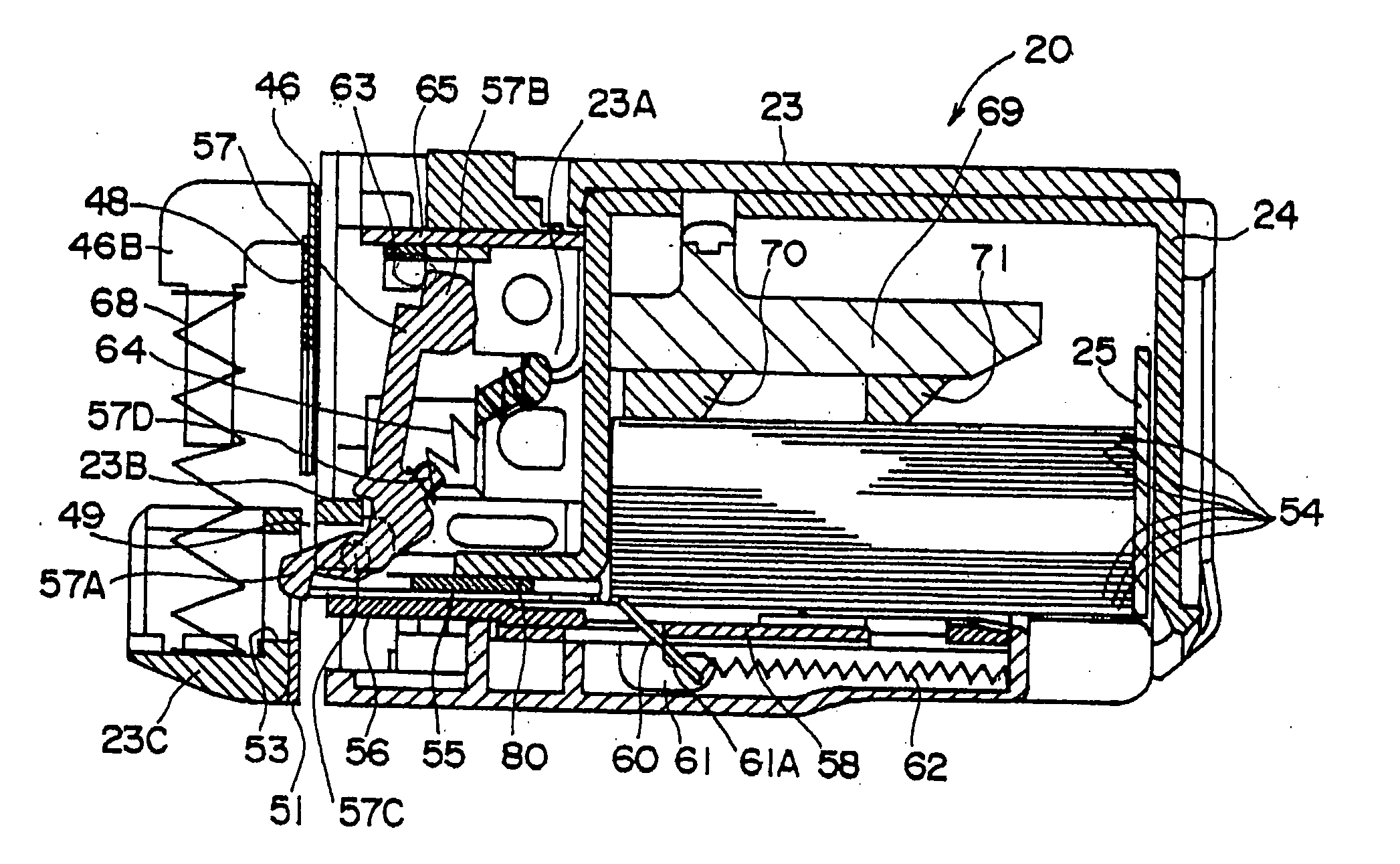

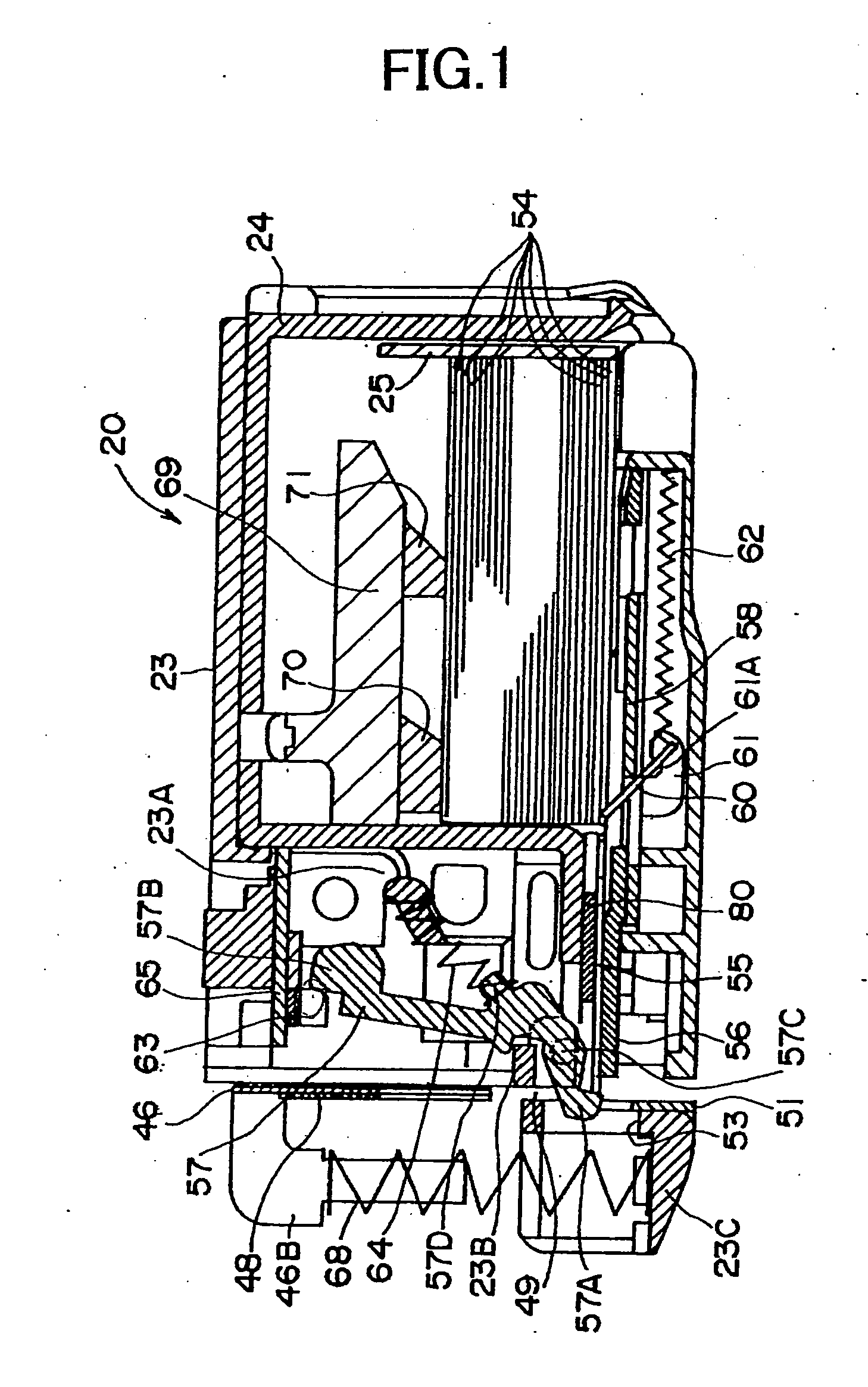

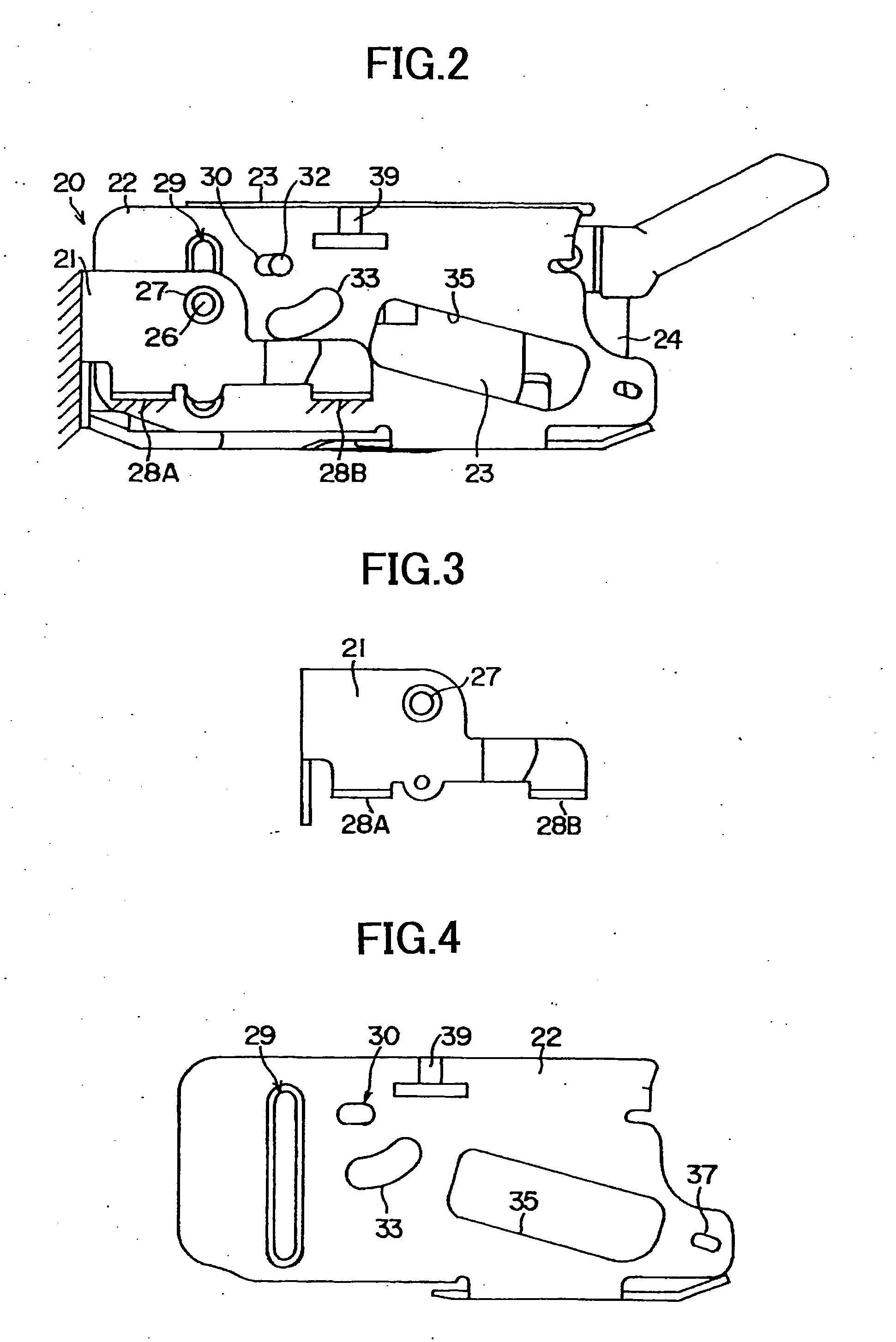

[0037] FIG. 2 shows an outlined construction of the electric stapler according to one embodiment. In FIG. 2, a reference numeral 20 shows an electric stapler. The electric stapler 20 comprises an outer casing 21 fixedly attached to a frame of a stacking mechanism of a copying machine, an inner casing 22 vertically movably supported by the outer casing 21, a magazine 23 swingably held in the inner casing 22, a cartridge casing 24 fitted into the magazine 23, and a cartridge 25 (See FIG. 1) received in the cartridge casing 24.

[0038] The outer casing 21 has a one side-opened rectangular planar shape to house the inner casing 22. As shown in FIGS. 3 and 9, a side plate of the outer casing 21 is provided with a fitting hole 27 for a guide pine 26. The outer casing 21 has projecting pieces 28A and 28B proje

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric charge | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap