Automotive vehicle dent guard panels

a technology for automobiles and dent guards, applied in vehicle components, bumpers, vehicular safety arrangments, etc., can solve the problems of limited protection coverage of devices, many previous disclosed inventions experience critical disadvantages, etc., to prevent dings and scratches unwarranted, maintain vehicle appearance, and maintain independence and livelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

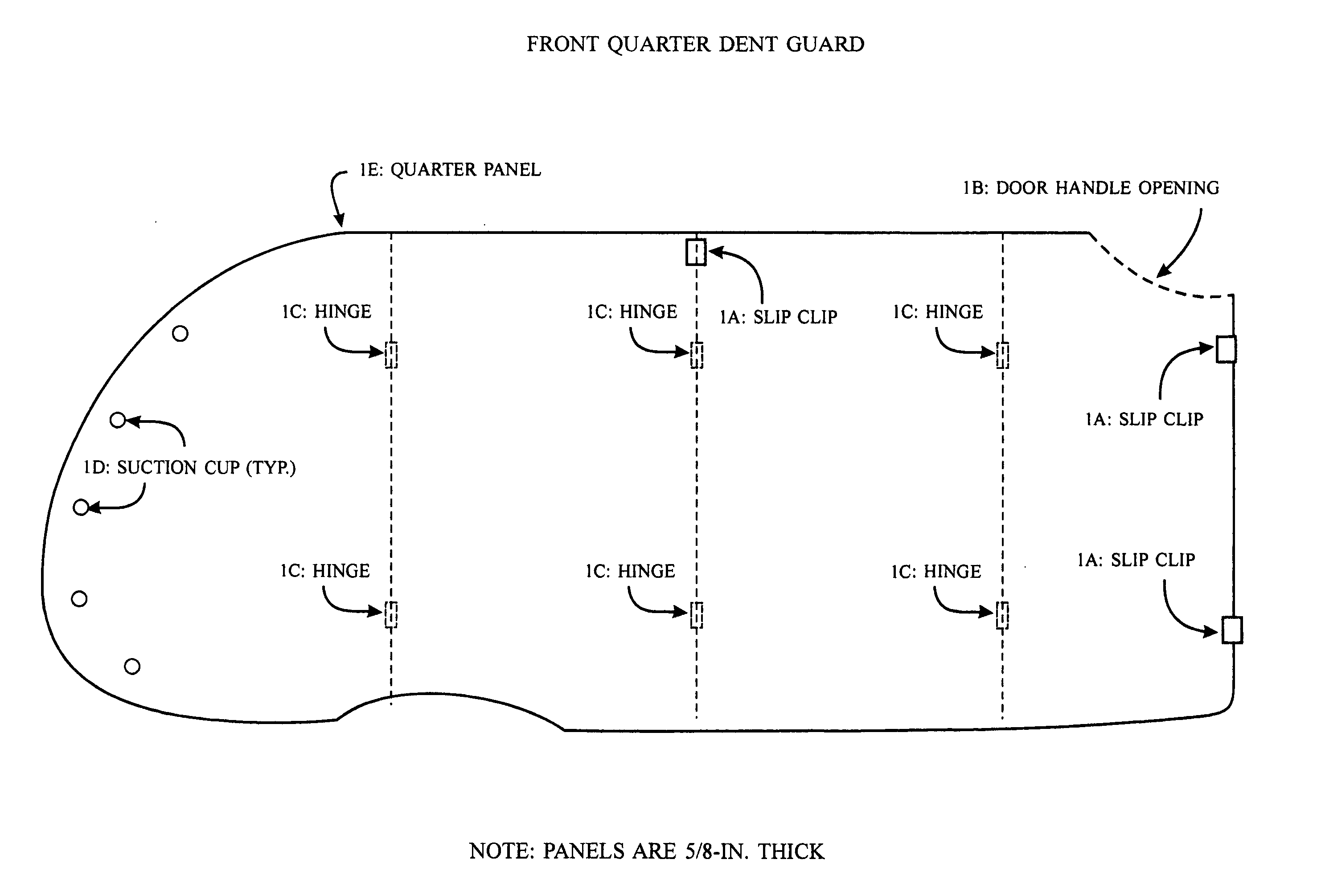

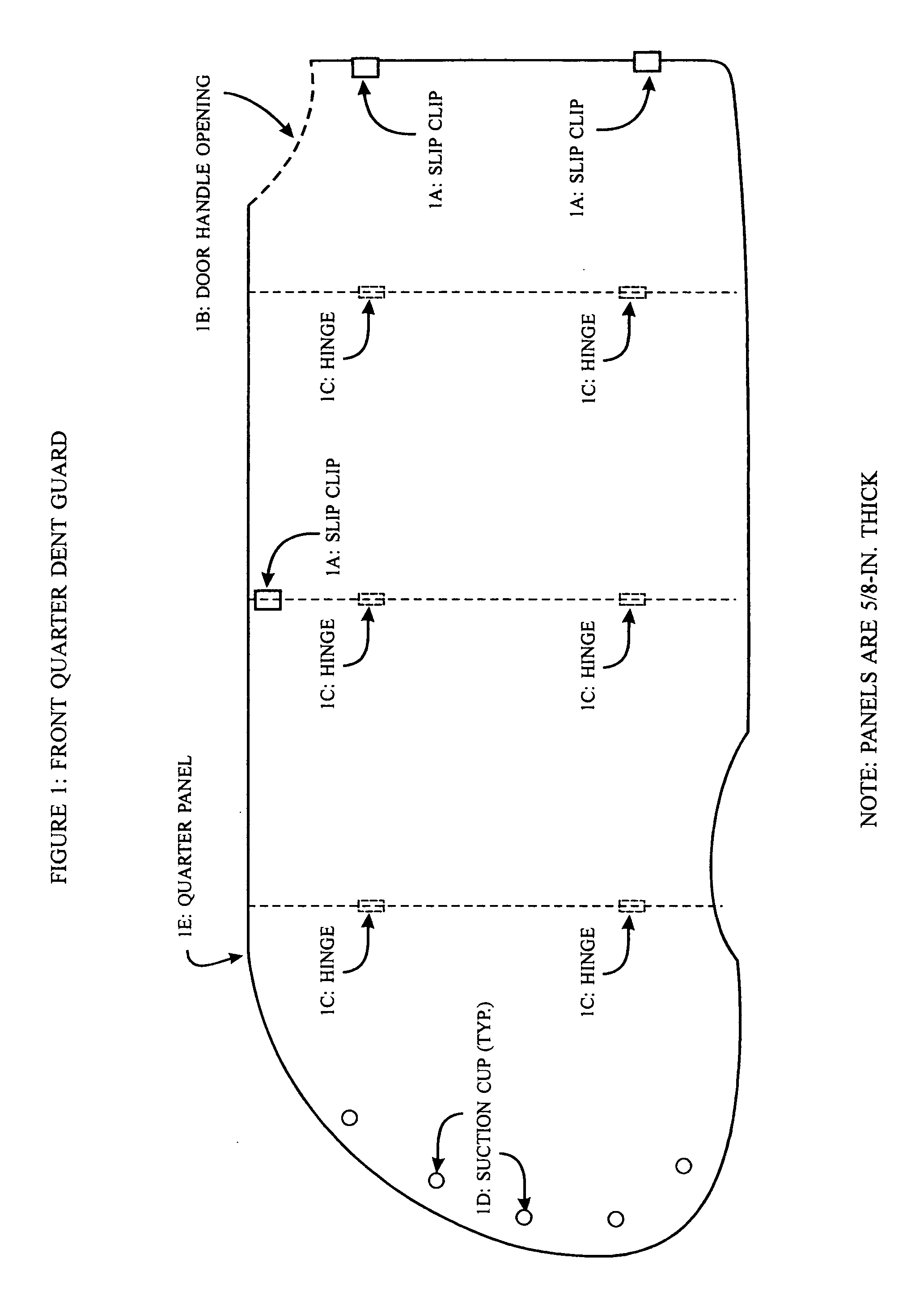

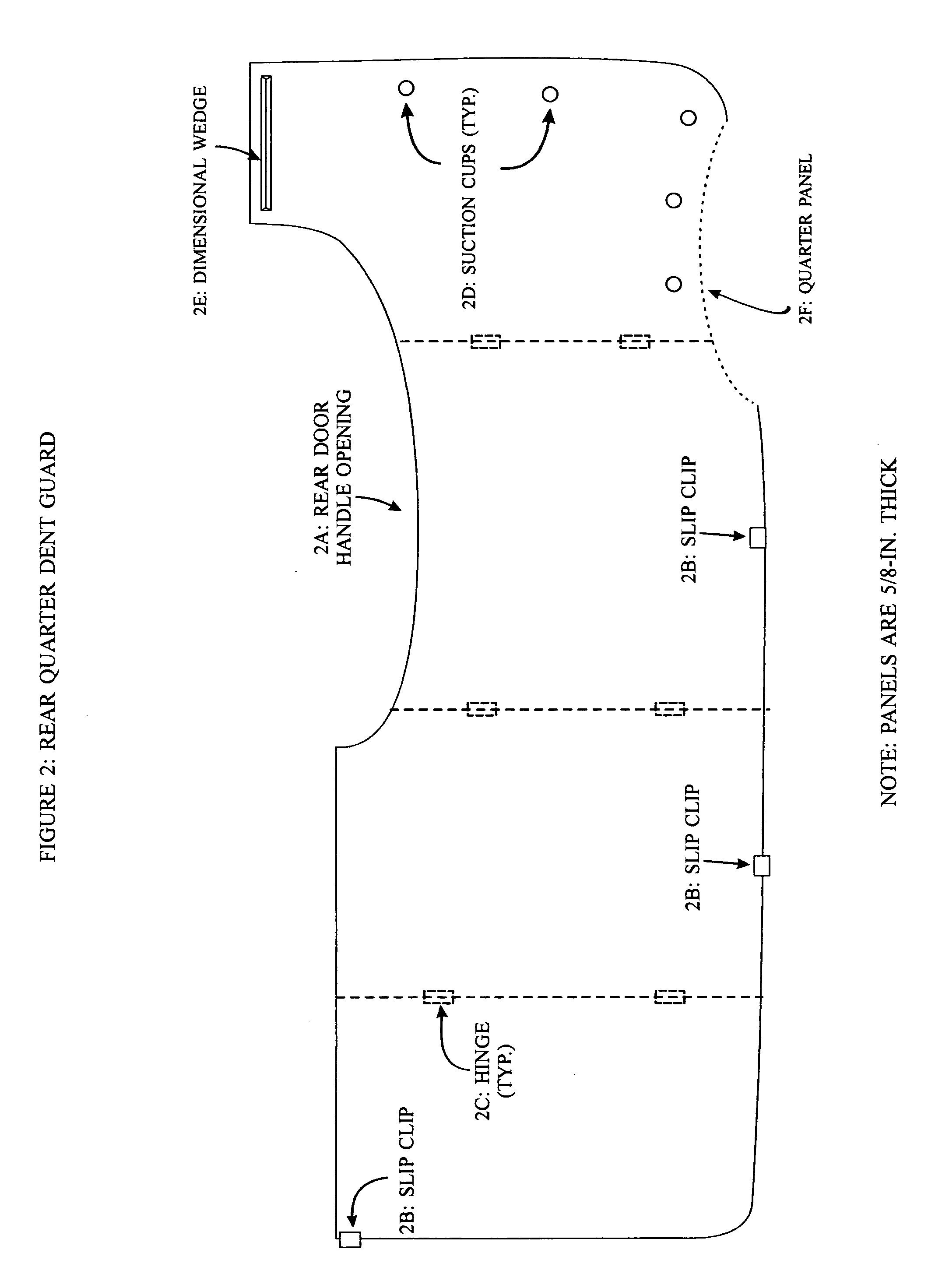

[0019] The present invention consists of vehicle dent guard protection panels. The preferred depiction, as shown in the provided FIGS. 1, 2, 3, and 4 are adaptable or can be customized for any vehicle door. The primary components are element 1 and second element 2, and third element 3, and fourth element 4.

[0020] The first step is to construct a standard vehicle front quarter and door panel molds. Translucent vinyl is inserted into the molds to form the dent guards that are generally flat on one side with wedge-shaped stem protrusions on the opposite side and suction cup supports. The front quarter and door dent guard panels are each cut in half and reconnected with vinyl hinges. The completed front quarter dent guard panel is illustrated in FIG. 1.

[0021] Primary element 1 is comprised of a ⅝ inch thick vinyl vehicle front quarter panel and door conjoined in FIG. 1. The quarter panels that has a generally flat surface on one side and has wedge-shaped translucent vinyl shock absorbing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap