Misfire detector for multi-cylinder engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

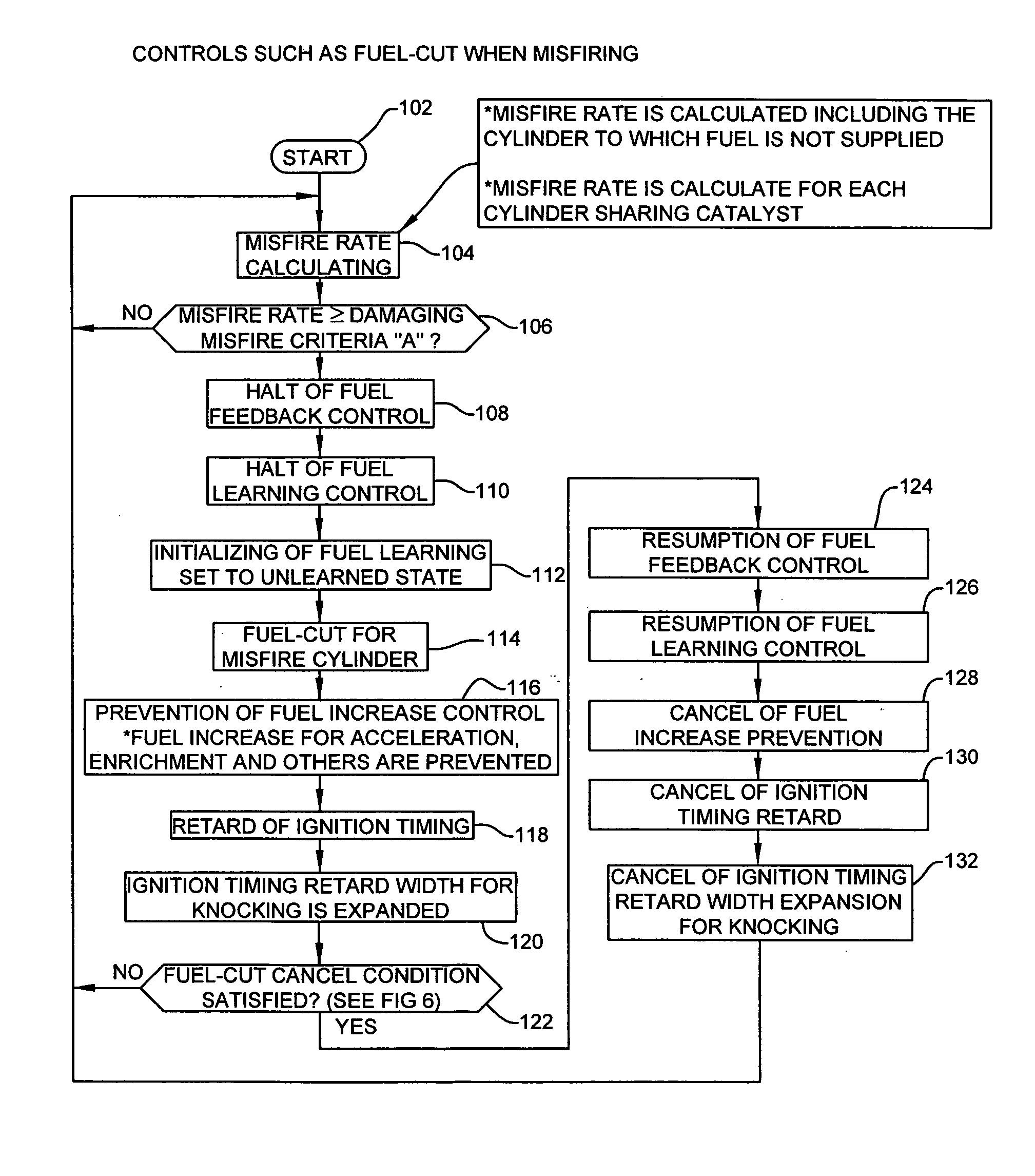

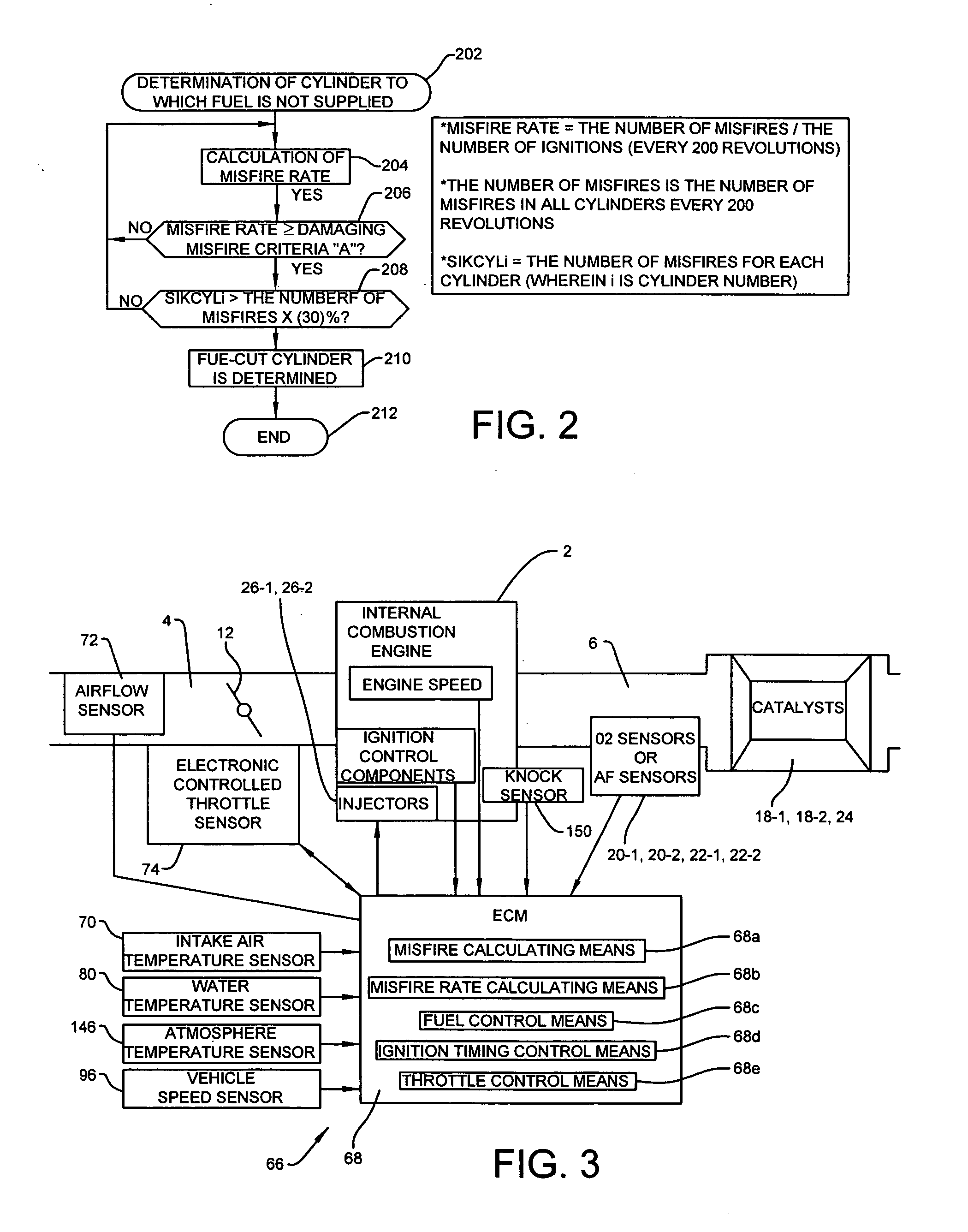

[0096] Operation of the second embodiment is explained with reference to a flowchart of FIG. 8 for throttle control of the misfire detector when misfiring. A program for the throttle control for misfire starts in step 302. The rate of misfire for each cylinder is calculated in step 304. Then a determination is made in step 306 as to whether this misfire rate is greater than or equal to the damaging misfire criteria A at which the catalyst may be damaged.

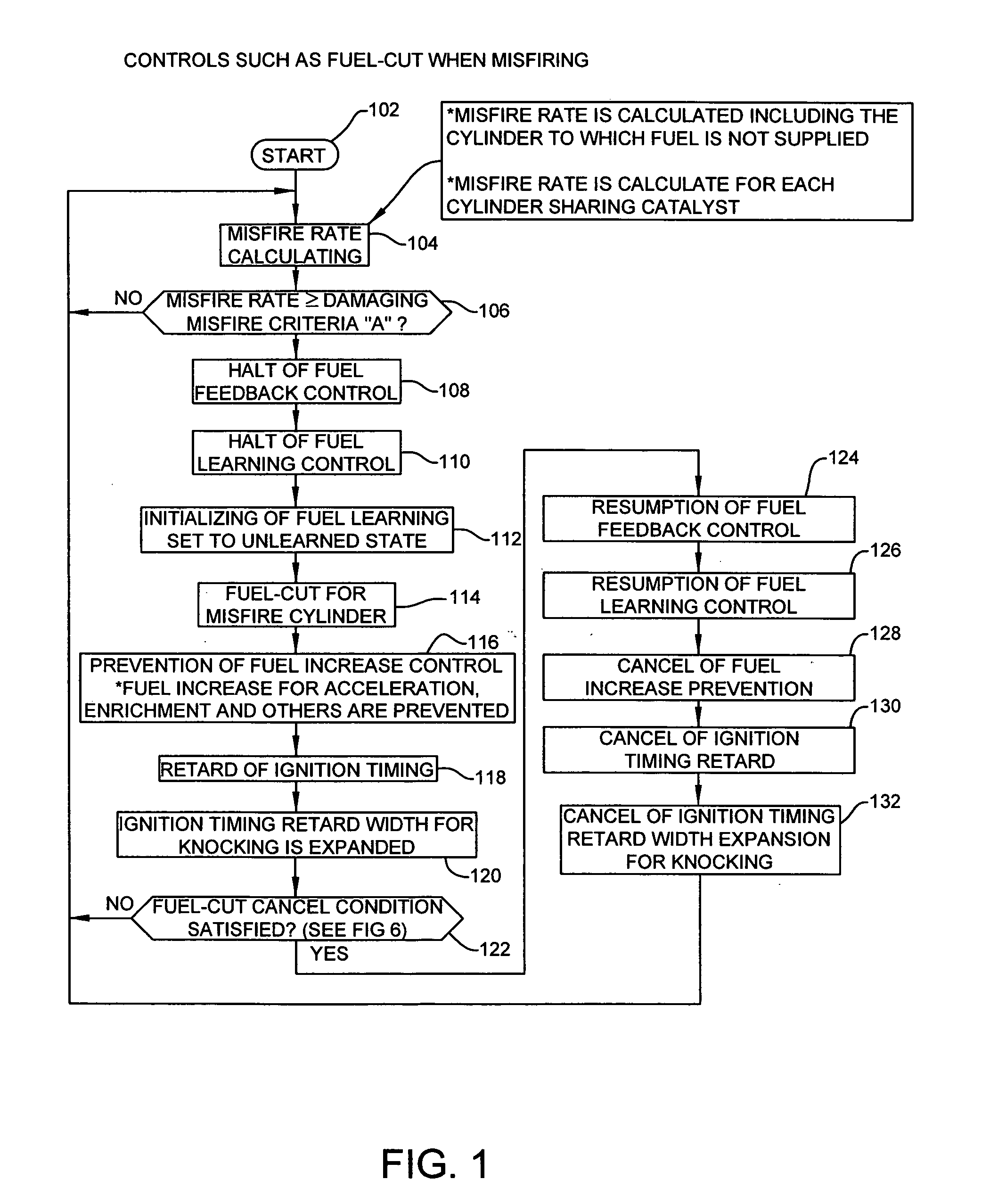

[0097] The rate of misfire is calculated for every 200 revolutions of the engine speed for each cylinder. This calculation includes the cylinder for which the fuel cut is performed. For the V-type engine, the misfire rate is calculated for each cylinder bank. Also, the misfire rate is calculated for each cylinder that shares the catalyst. The damaging misfire criteria A is calculated from a table based on the engine speed and the engine load (see FIG. 5).

[0098] In the determination in step 306 as to whether the misfire rate is greater

third embodiment

[0104]FIGS. 11 and 12 illustrate the present invention.

[0105] The third embodiment of the present invention is characterized in that in the misfire detector for the multi-cylinder engine, the misfire control includes (1) the fuel cut control for misfire cylinders by the fuel cut means to stop supplying the fuel to the misfire cylinders, (2) the control to prevent the fuel feed back control and the fuel leaning control and to initialize the correction values of both the fuel feed back control and the fuel leaning control, and (3) an engine speed control to limit the engine speed below a predetermined engine speed irrespective of the opening degree of the acceleration. Alternatively, the third embodiment of the present invention is characterized in that in the misfire detector for the multi-cylinder engine, the misfire control includes (1) the fuel cut control for misfire cylinders by the fuel cut means to stop supplying the fuel to the misfire cylinders, (2) the control to prevent the f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap