Horizontal type orbiting vane compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Now, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

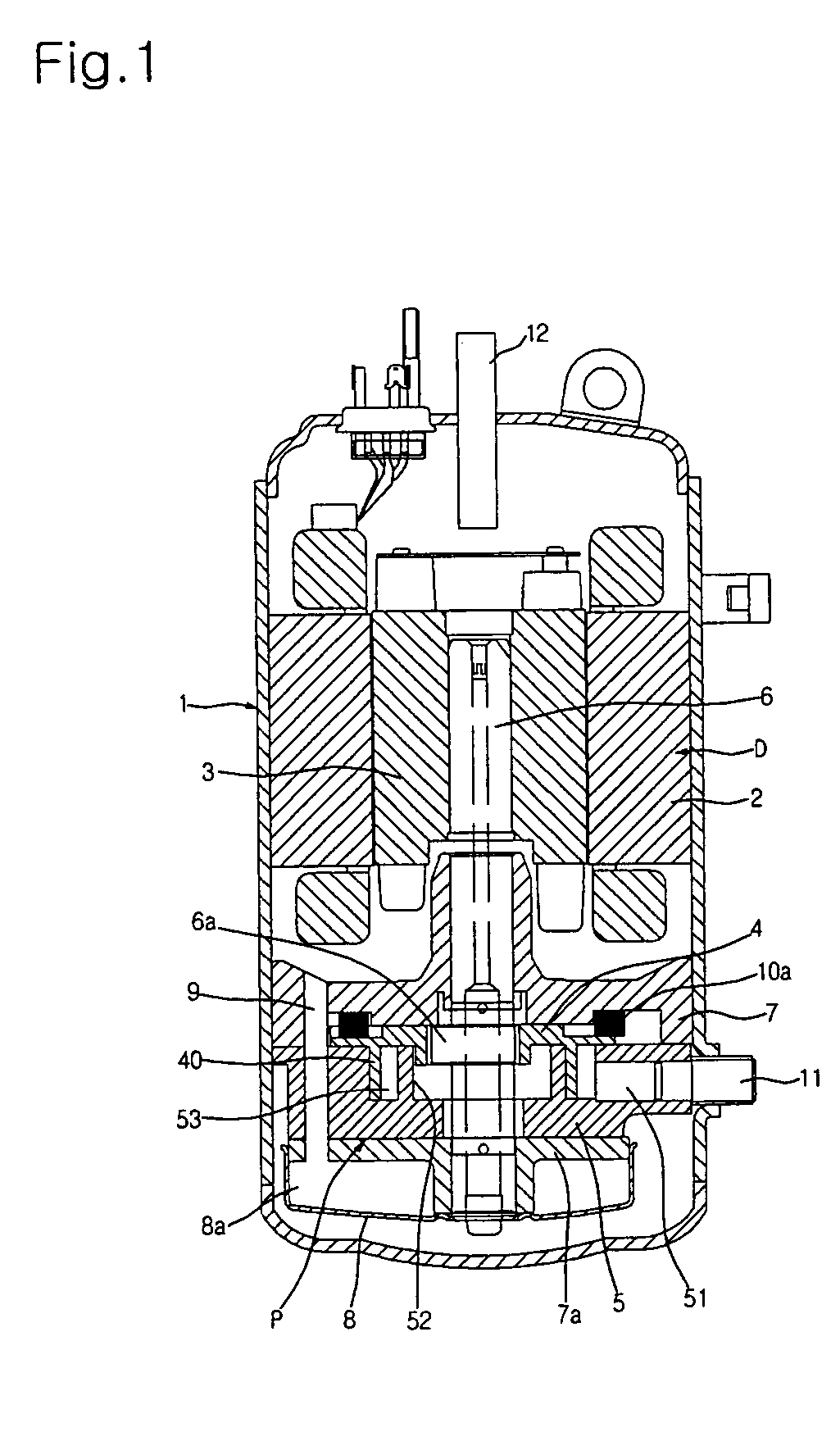

[0043]FIG. 3 is a longitudinal sectional view illustrating the overall structure of a horizontal type orbiting vane compressor according to the present invention. As shown in FIG. 3, the horizontal type orbiting vane compressor comprises: a hermetically sealed shell 100, which is horizontally disposed; a compression unit P disposed at one side in the shell 100; and a drive unit D disposed at the other side in the shell 100. The compression unit P and the drive unit D are connected to each other via a rotary shaft 150, which has an eccentric part 151.

[0044] The drive unit D comprises: a stator 110 fixedly disposed in the shell 100; and a rotor 120 disposed in the stator 110 for rotating the rotary shaft 150, which horizontally extends through the rotor 120, when electric current is supplied to the rotor 120.

[0045] The compression unit P comprises an orbi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap