Solid co-crystallized monoglyceride and fatty acid lactylate emulsifier and starch-complexing agent and method of producing same

a technology of co-crystallized monoglyceride and fatty acid lactylate, which is applied in the field of solid, powdered, highly functional starch complexing and emulsifier agents, can solve the problems of difficult to adapt hydrated distilled monoglyceride stearate emulsifiers to large-scale, automated bakeries or food processing plants, and the inability to function at the temperature conventionally employed, etc., to achieve convenient addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0026] A test was conducted of white pan bread produced by a conventional sponge and dough process known to those skilled in the art. The variables were as follows:

no emulsifier controlvolume 2950 cccrumb firmness 272 g0.375% SSL + 1% GMS 90volume 3138 cccrumb firmness 225.5 g0.625% of (70% SSL / 30%volume 3213 cccrumb firmness 190 gmonoglyceride co-melted)0.625% of (70% SSL / 30%volume 3000 cccrumb firmness 259.8 gmonoglyceride blended)

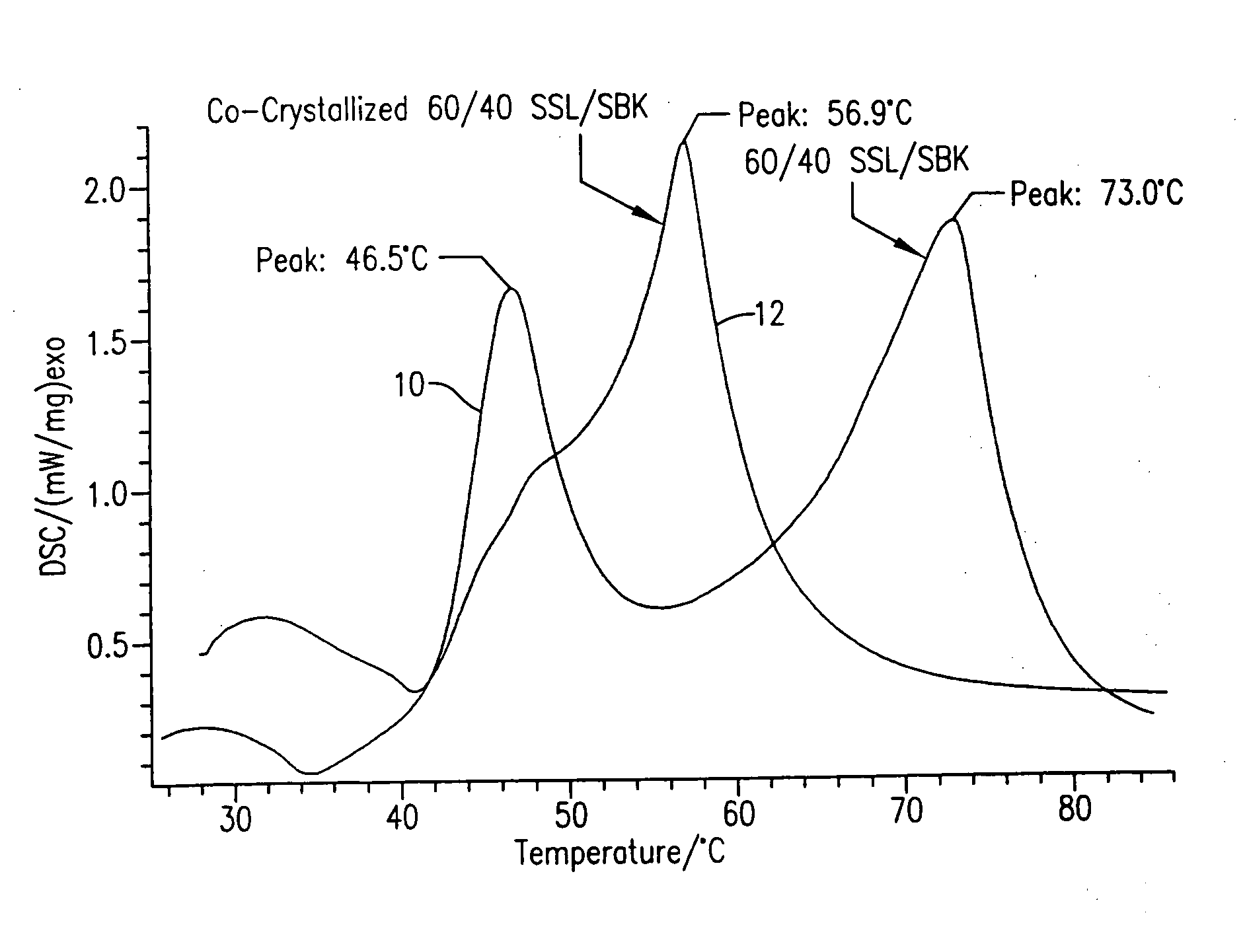

Crumb firmness was measured by the TA-XT2 Texture Analyzer (Texture Technologies Corp.) according to methods known to those skilled in the art. Volume was measured by the rapeseed displacement—known to those skilled in the art. The results demonstrated a significantly improved functionality when SSL and monoglyceride were co-crystallized as opposed to being blended without co-melting and co-crystallization.

[0027] Commercial grade monoglycerides do not exert their dual functions as a starch-complexing and dispersing agent until the temperature of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap