Automated control of razor blade colorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

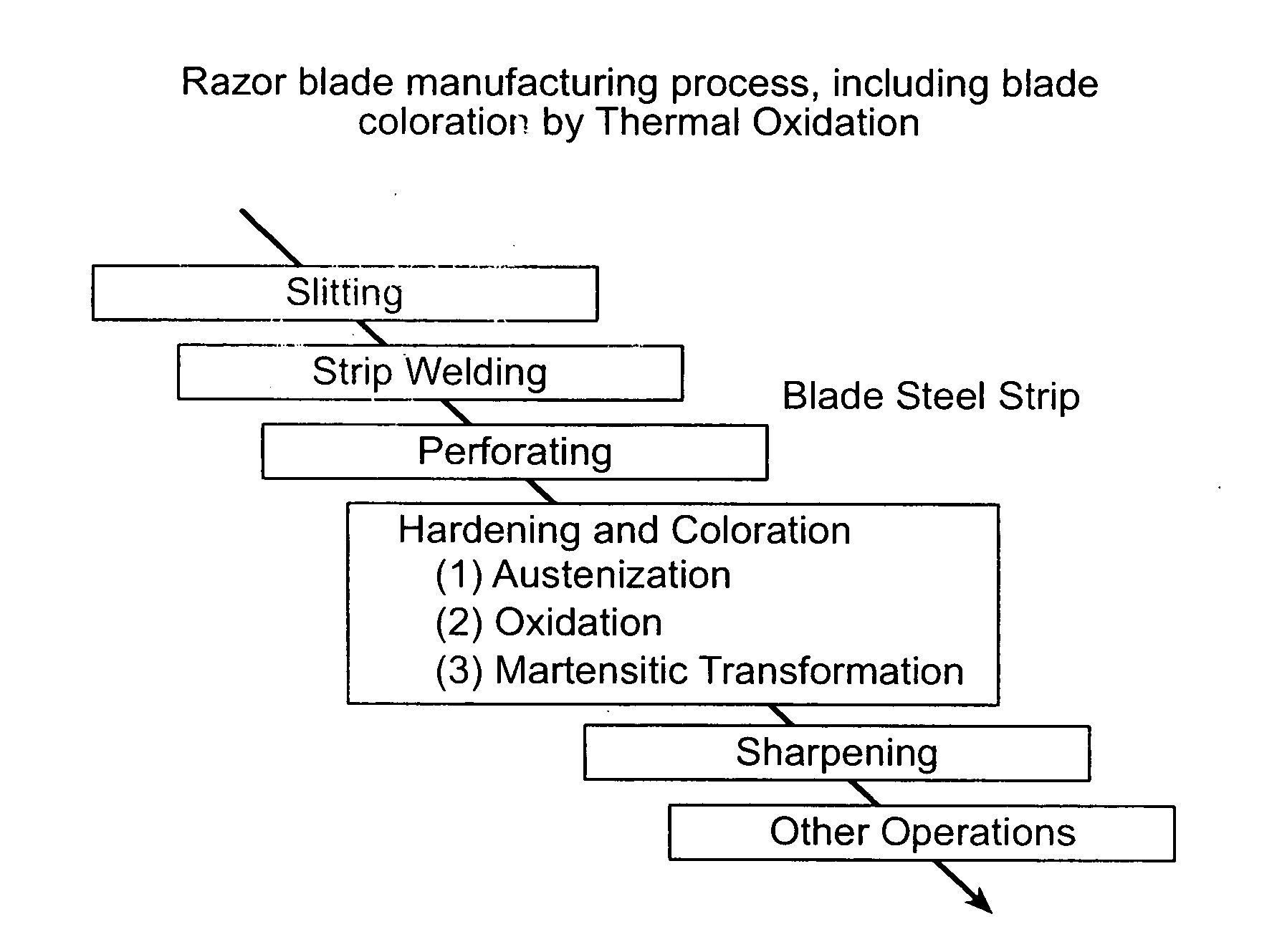

[0039] A suitable thermal oxide process for forming the colored oxide layer and manufacturing the razor blade is shown diagrammatically in FIG. 1. First, a sheet of blade steel is slit into strips. The strips are then welded together and then perforated for ease of handling during subsequent processing.

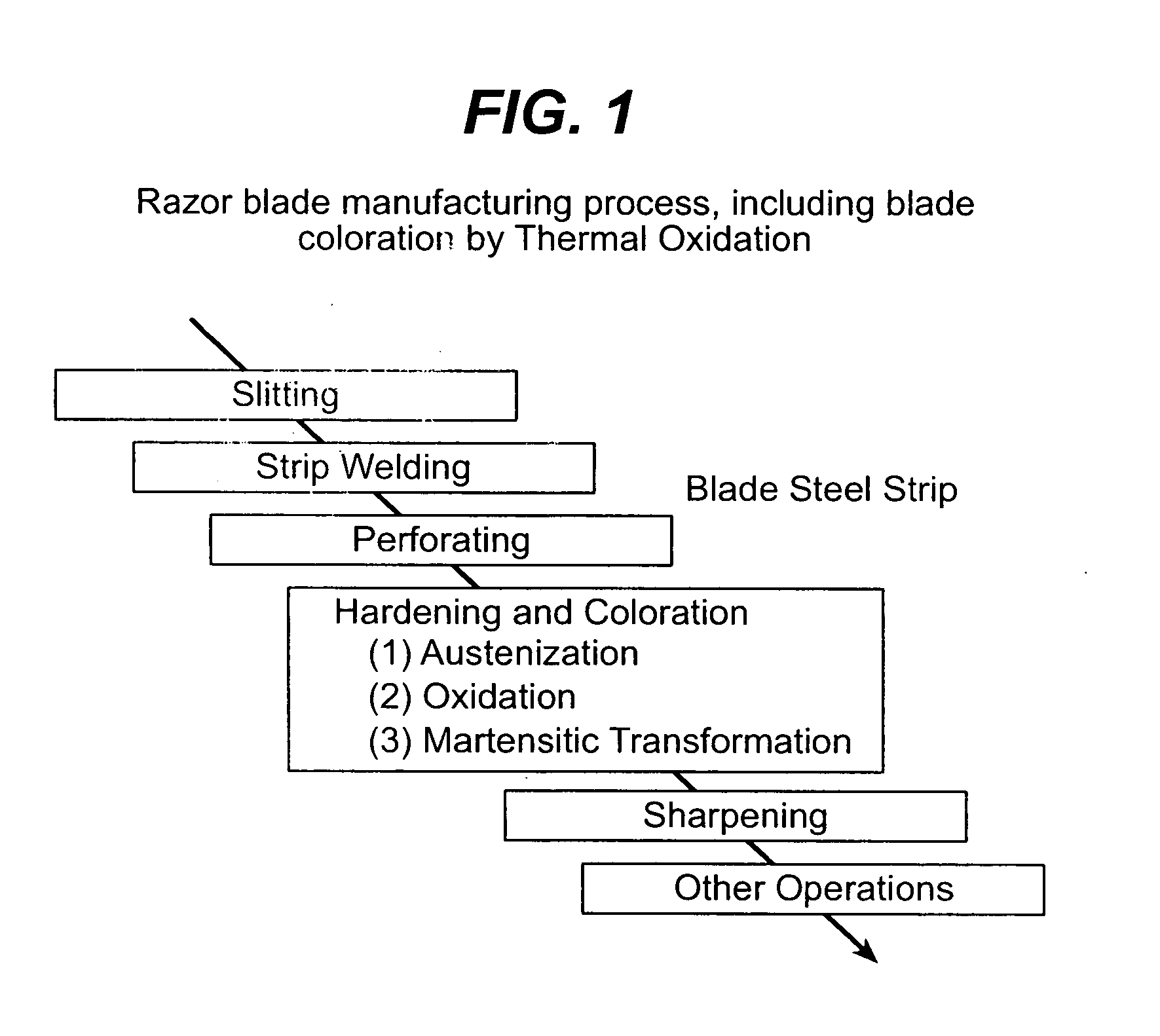

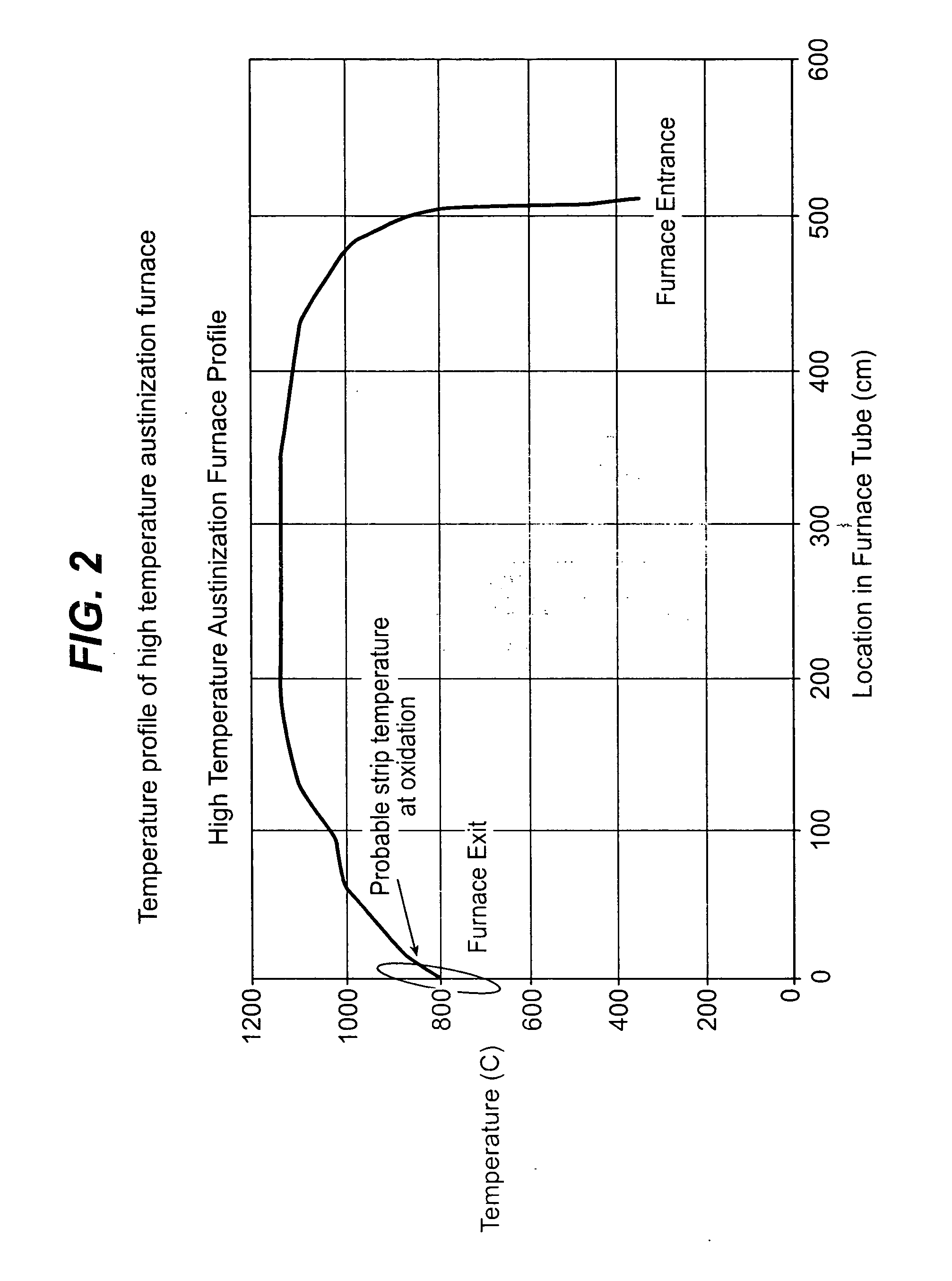

[0040] When the desired sequence of pre-hardening steps has been completed, the blade material is subjected to a hardening process, which includes austenization of the stainless steel. A typical temperature profile for the hardening process, which is conducted in a tunnel oven, is shown in FIG. 2. The material is quickly ramped up to a high temperature, e.g., approximately 1160° C., maintained at this temperature for a period of time, during which austenization of the stainless steel occurs, and then allowed to cool. A forming gas (e.g., including hydrogen and nitrogen) flows through the high temperature zone of the oven during austenization. The composition and flow rate of the forming

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap