Chemical Mechanical Polishing Pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

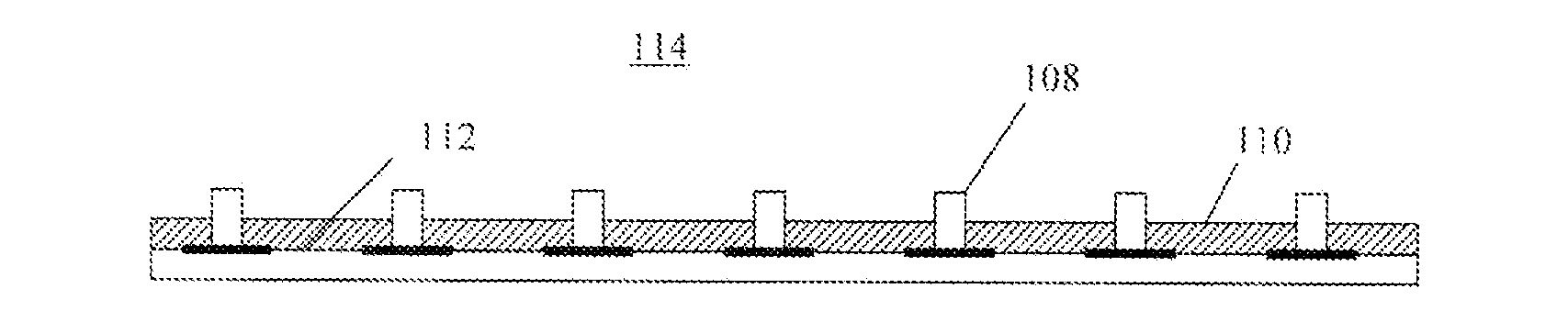

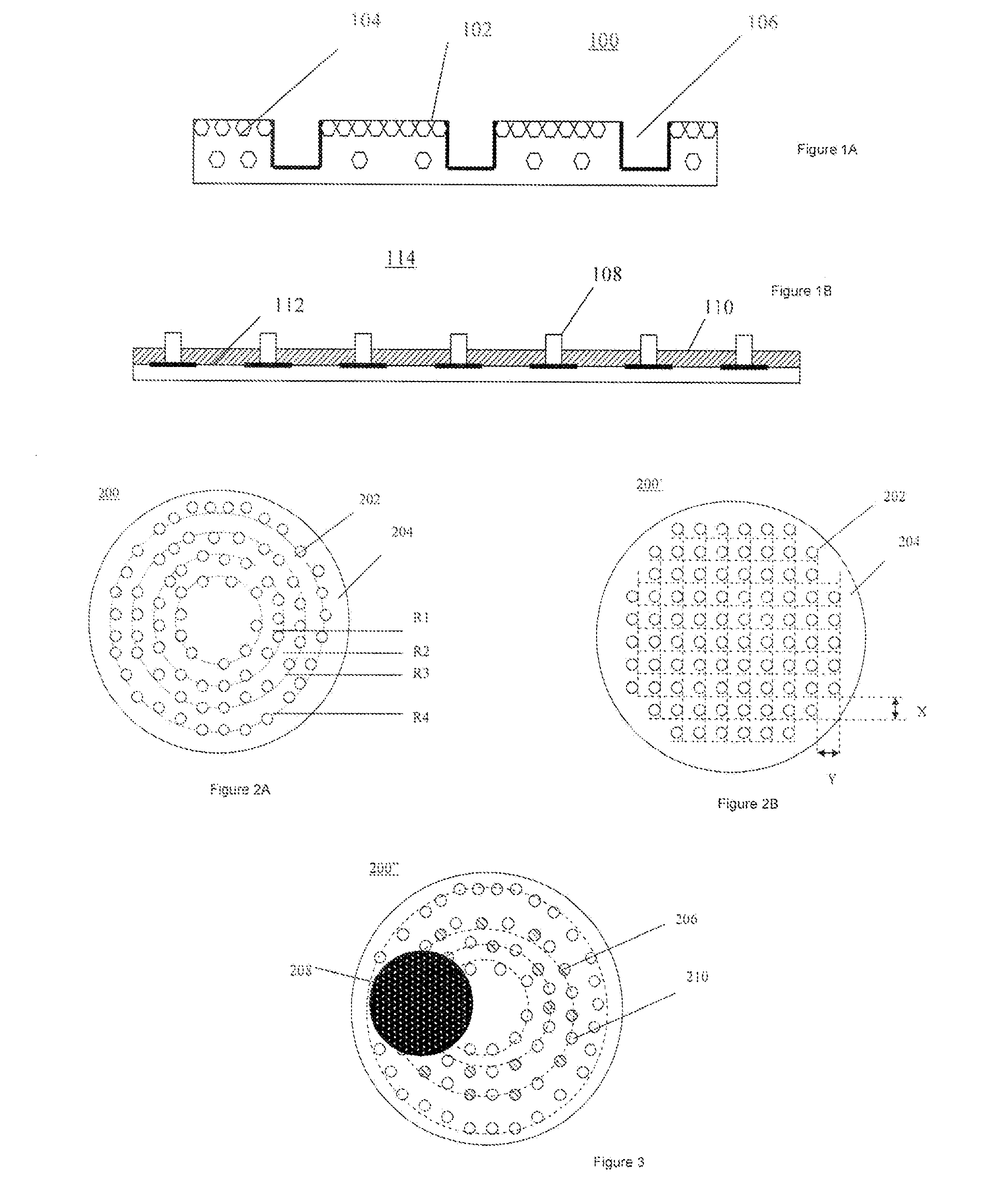

[0016]Described herein is a CMP polishing pad which allows for establishing a predefined, non-planar material removal profile. In one embodiment, the pad includes polishing elements, which are placed on an underlying compressible foam and protrude through holes in a guide plate overlaid on that foam. The nominal size of each polishing element is 0.25 inches and the height thereof is 0.160 inches. The compressible foam is nominally 0.060″ thick.

[0017]Note that although the present polishing pad is discussed with reference to certain illustrated embodiments, the scope of the present invention is not intended to be limited thereby. Instead, the present invention should only be measured in terms of the claims, which follow this description.

[0018]The present pad design enables the application very uniform pressure onto a wafer and eliminates (or at least substantially reduces) edge effect typically associated with full sheet polishing pads. This translates to a very uniform material removal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap