Power crimping device and method for crimping building panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

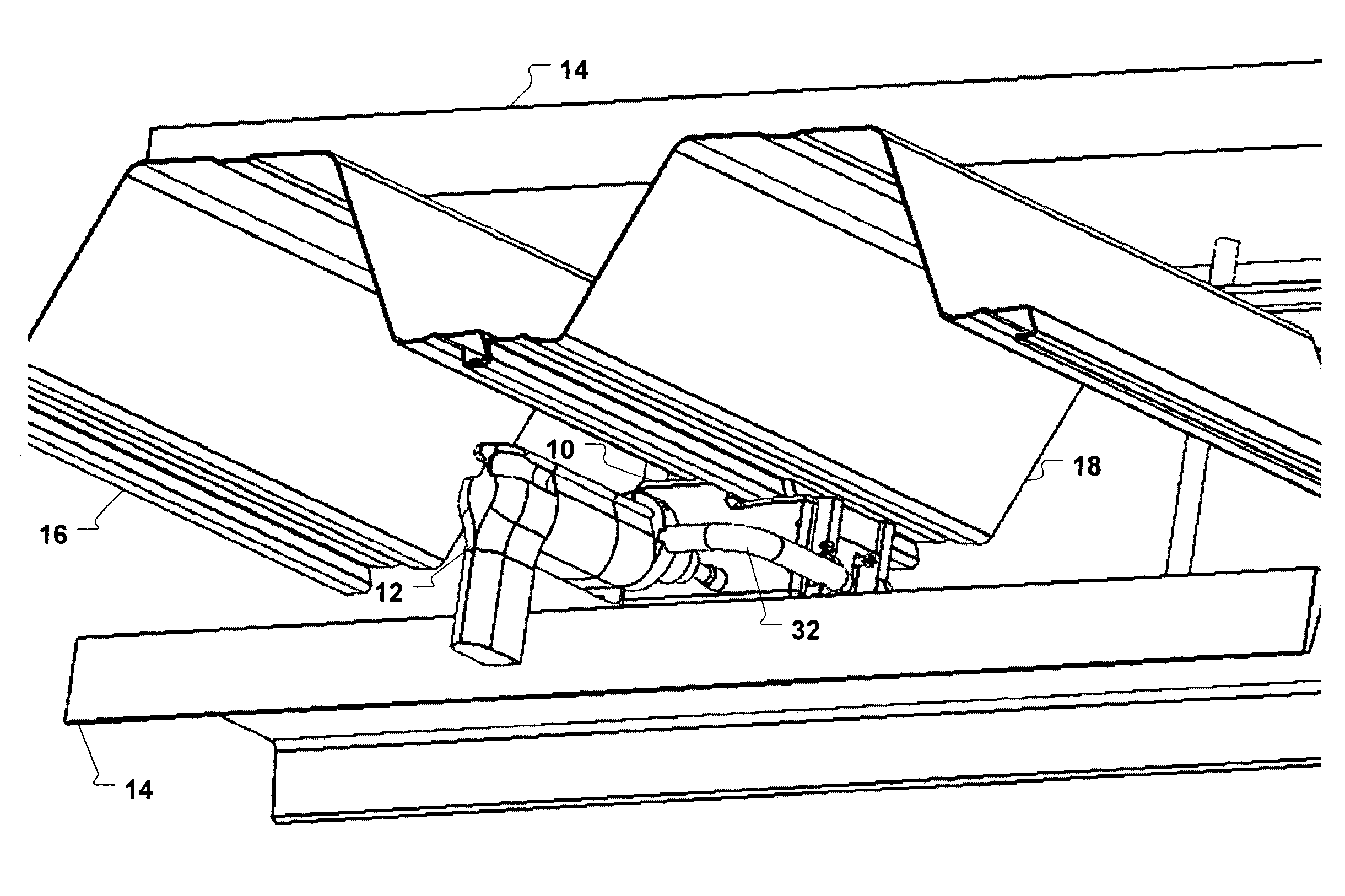

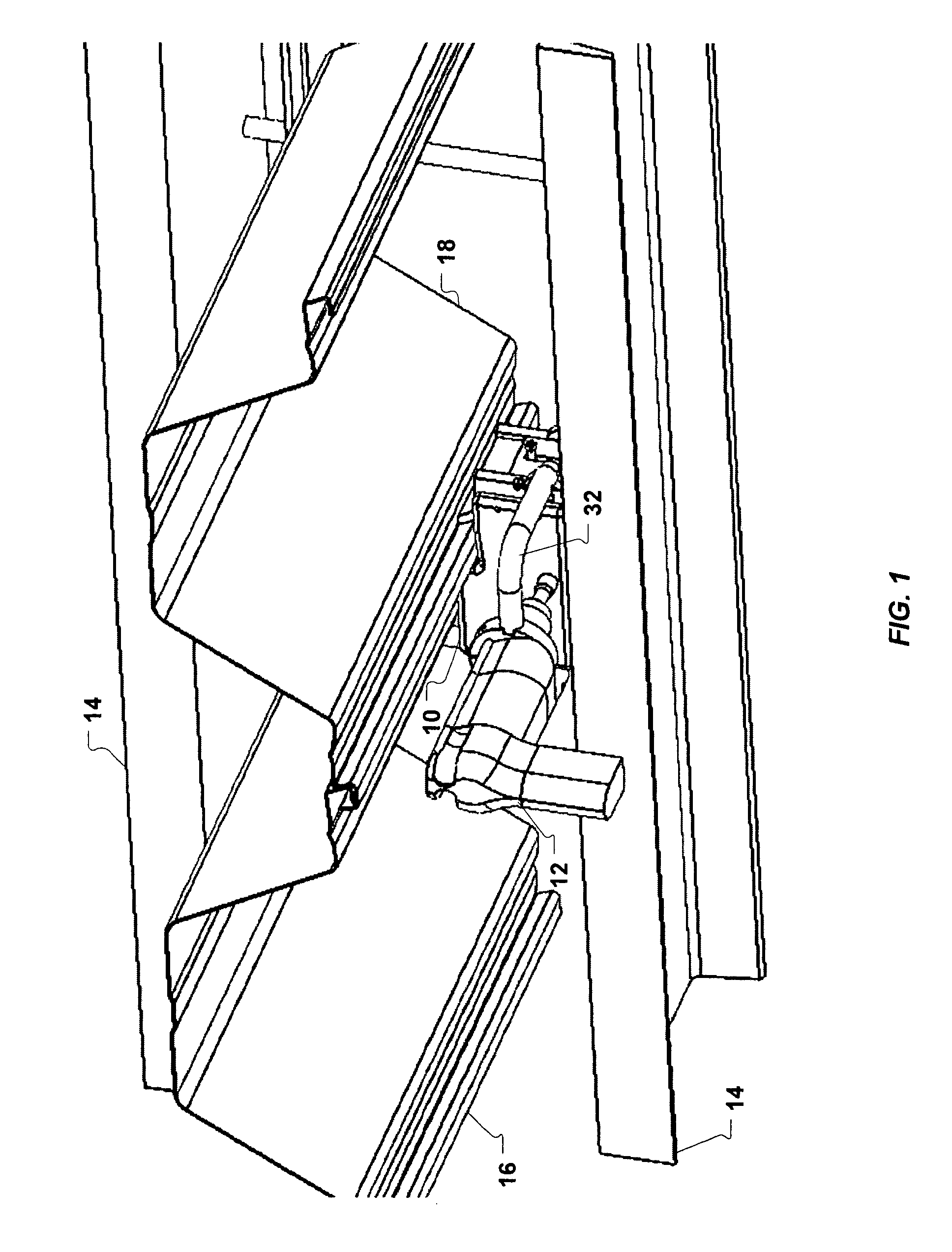

[0025]Certain features of the exemplary embodiments described herein are described with reference to directions, e.g., up, and down. With reference to FIG. 1, for the purposes of this disclosure, up, upwardly, and the like refers to a direction from the crimping device 10 generally toward the building panels 16, 18. Down, downwardly, and the like refers to the direction from the building panels 16, 18 generally toward the crimping device 10. Thus the top of the crimping device 10 would refer to a side of the crimping device facing the building panels 16, 18 and the bottom of the crimping device 10 would refer to an opposing side of the crimping device 10, for example. Obviously the directions are relative and are described for illustrative purposes only—they should not be construed to limit the scope of the disclosure or the claims.

[0026]FIGS. 1-7 illustrate an exemplary crimping device 10 for crimping together edge portions of adjacent building panels in accordance with certain embodi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap