Method for tracking feed quality of forage crops stored in horizontal structures as the crop is removed

a technology of horizontal structure and forage crop, which is applied in the field of tracking the feed quality of forage crop stored in horizontal structure as the crop, can solve the problems of limited effectiveness of this system and inability to identify the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The method that has been invented can be used to identify the feeding quality of any forage or grain crop stored in horizontal structure. Forage crops that are commonly chopped and stored in horizontal structures include whole-plant corn silage, alfalfa hay silage, grass silage, ground ear corn, forage sorghum and small grain silages. Alternatively grain crops can be ground or processed to also be stored in horizontal structures.

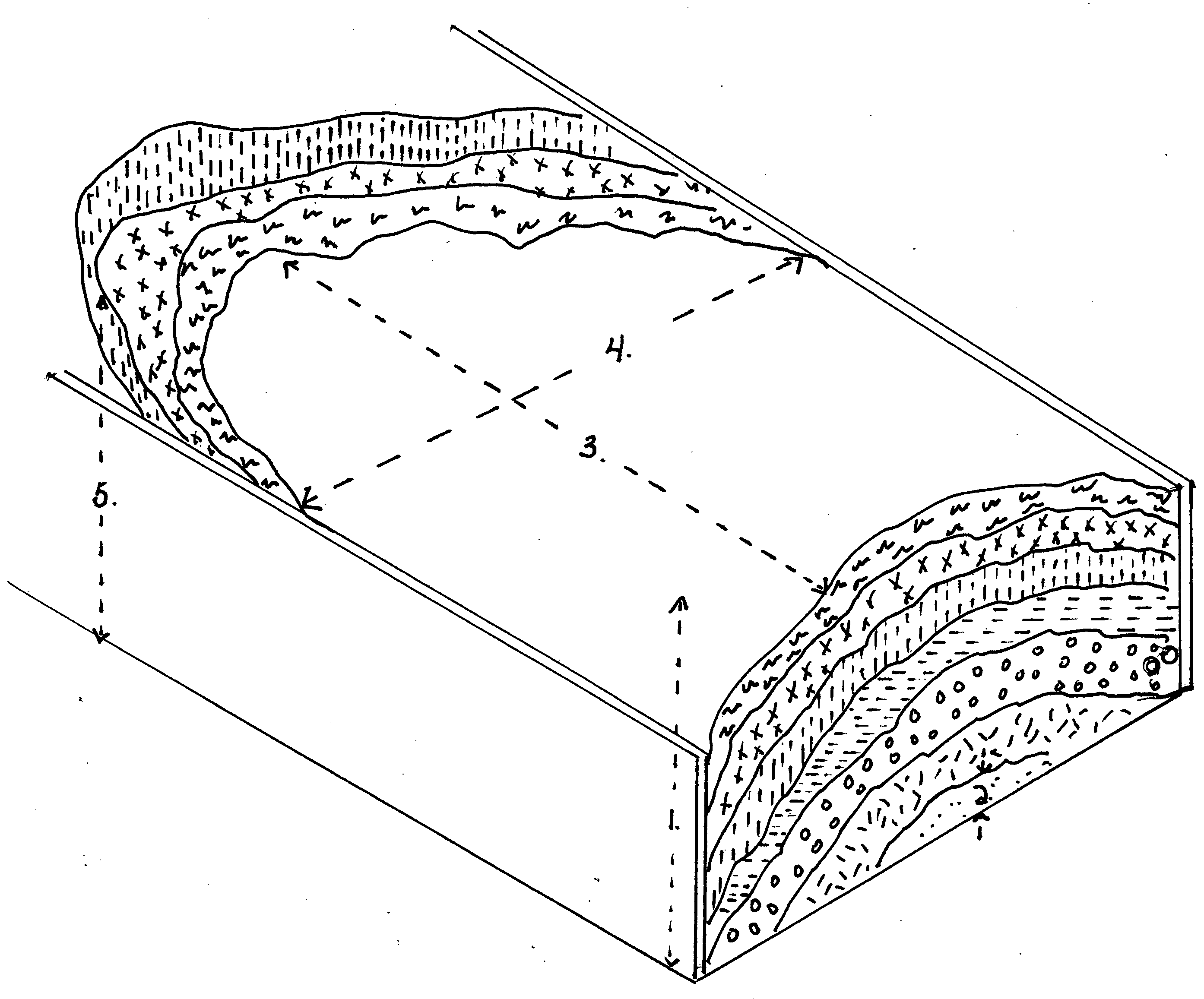

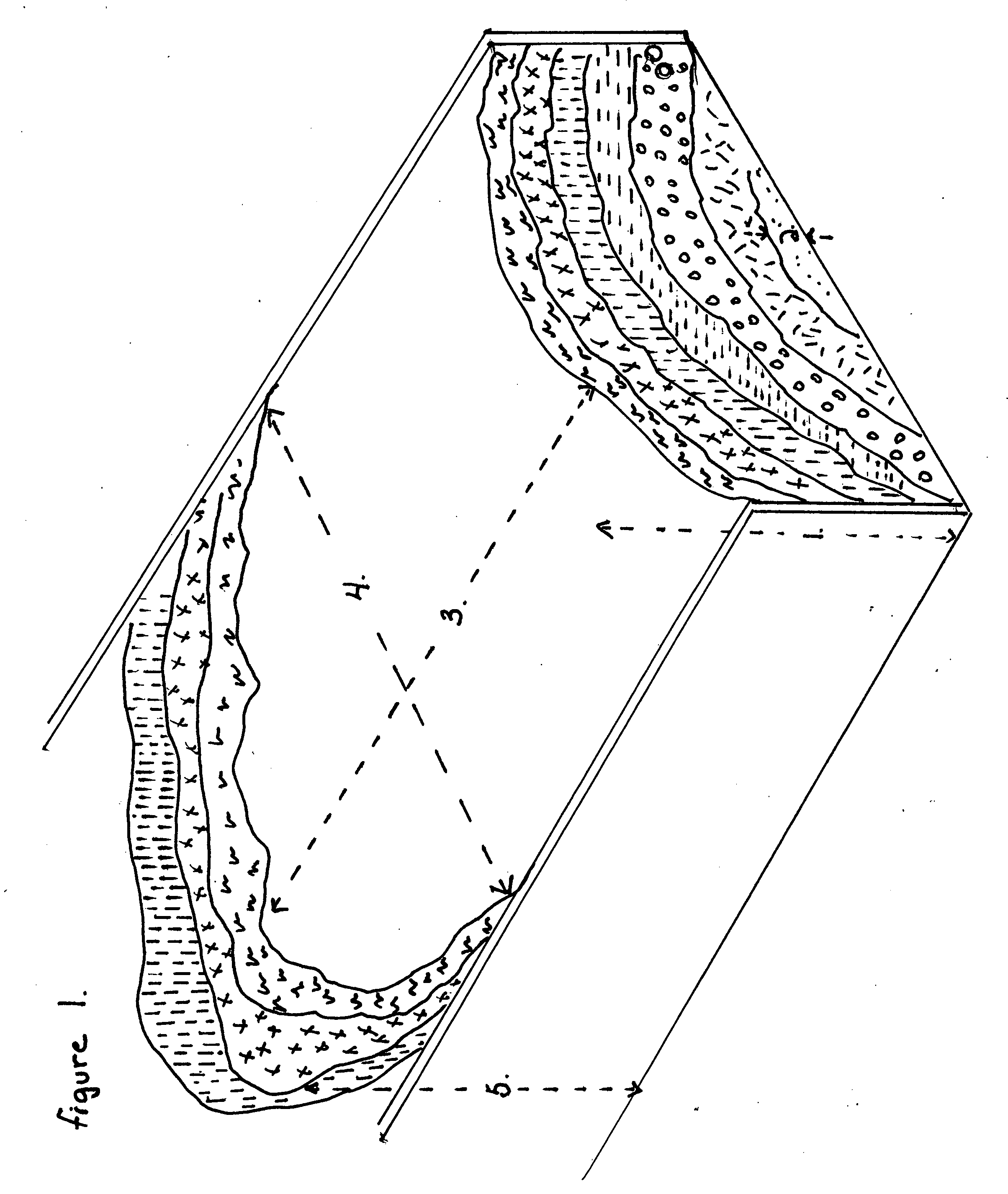

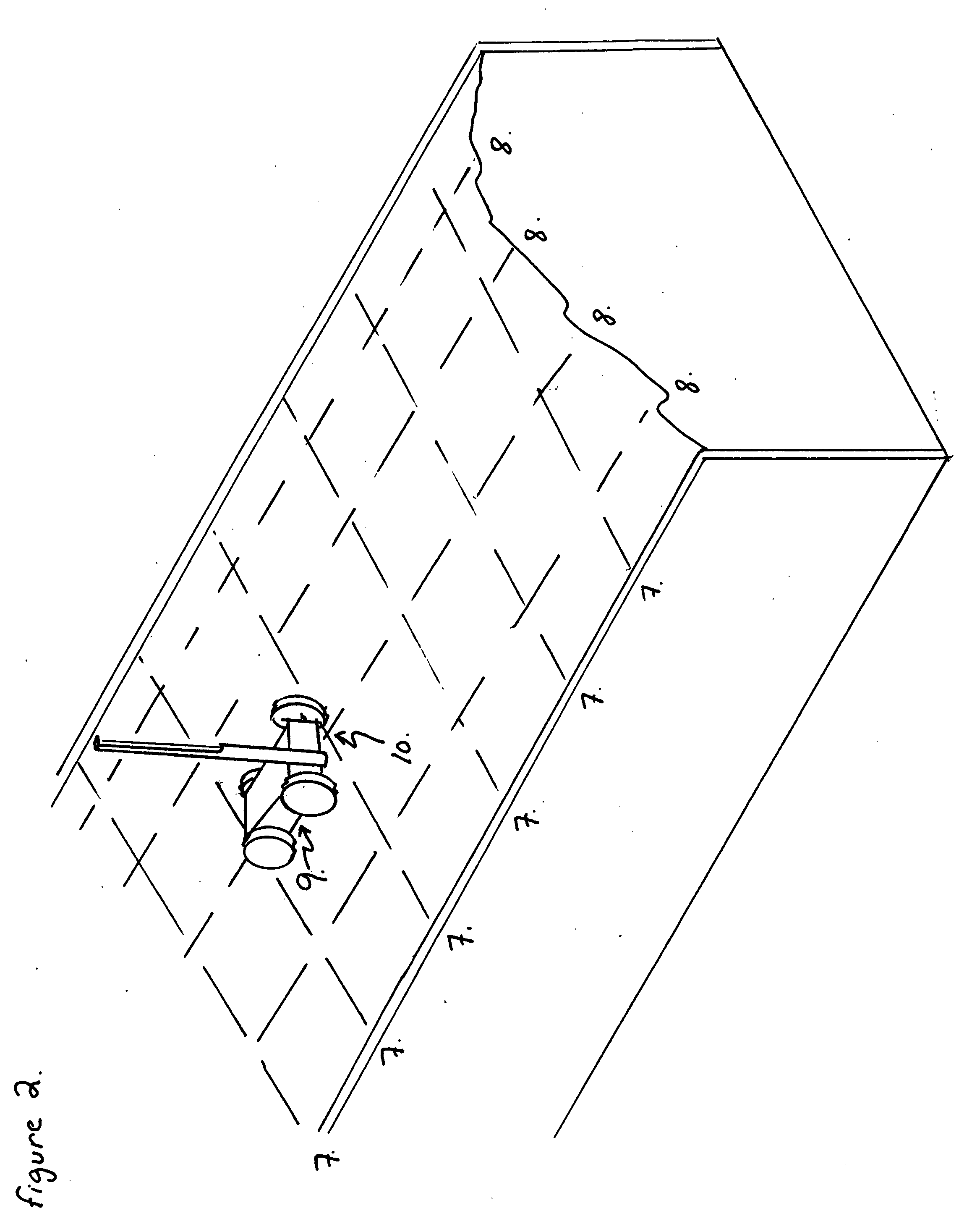

[0015]Horizontal structures include piles, above-ground bunkers and in-ground pits. These storage structures are typically filled to a depth between ten and thirty feet 1-1. The forage material is brought to the storage structure from various fields of origin during the filling period in loads of material ranging from three to twenty tons. The individual loads are spread into the storage structure by an implement such as a tractor with a front blade resulting in a layer for each load between two and twelve inches thick 1-2 and extending into the storage s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap