Three part tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

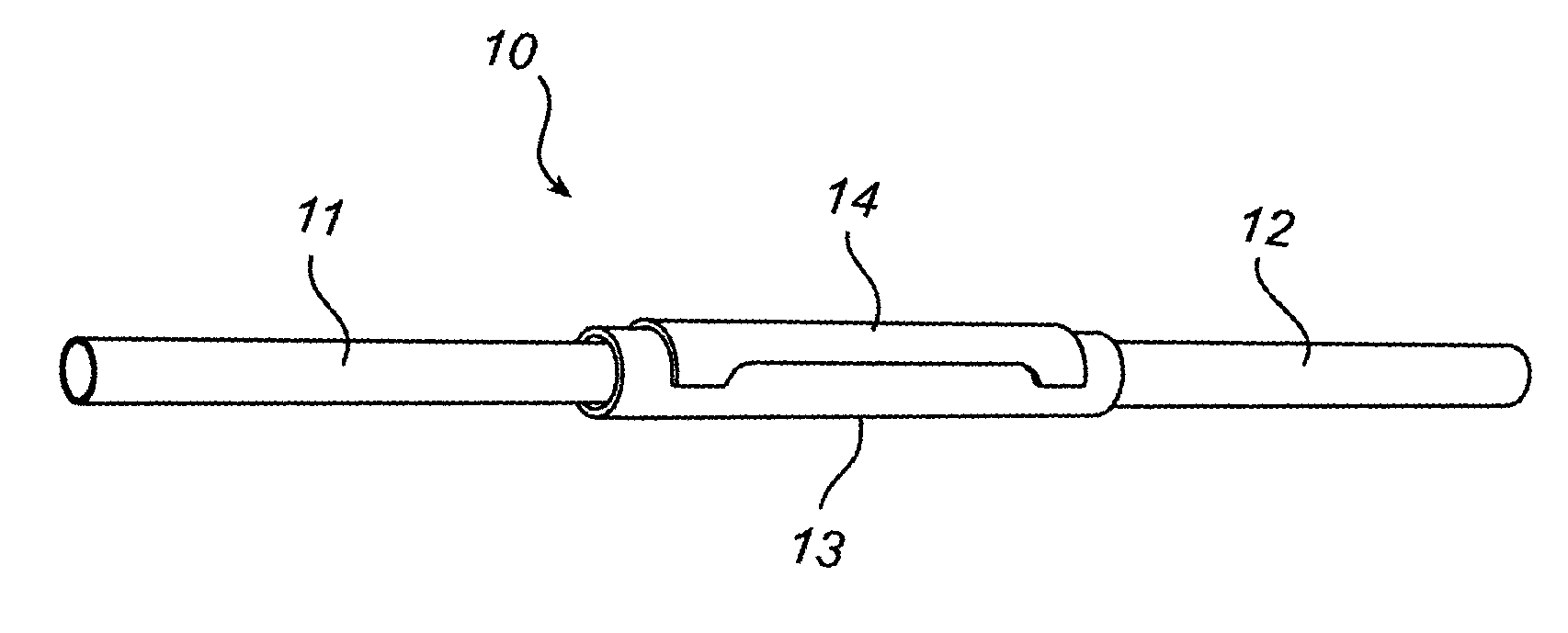

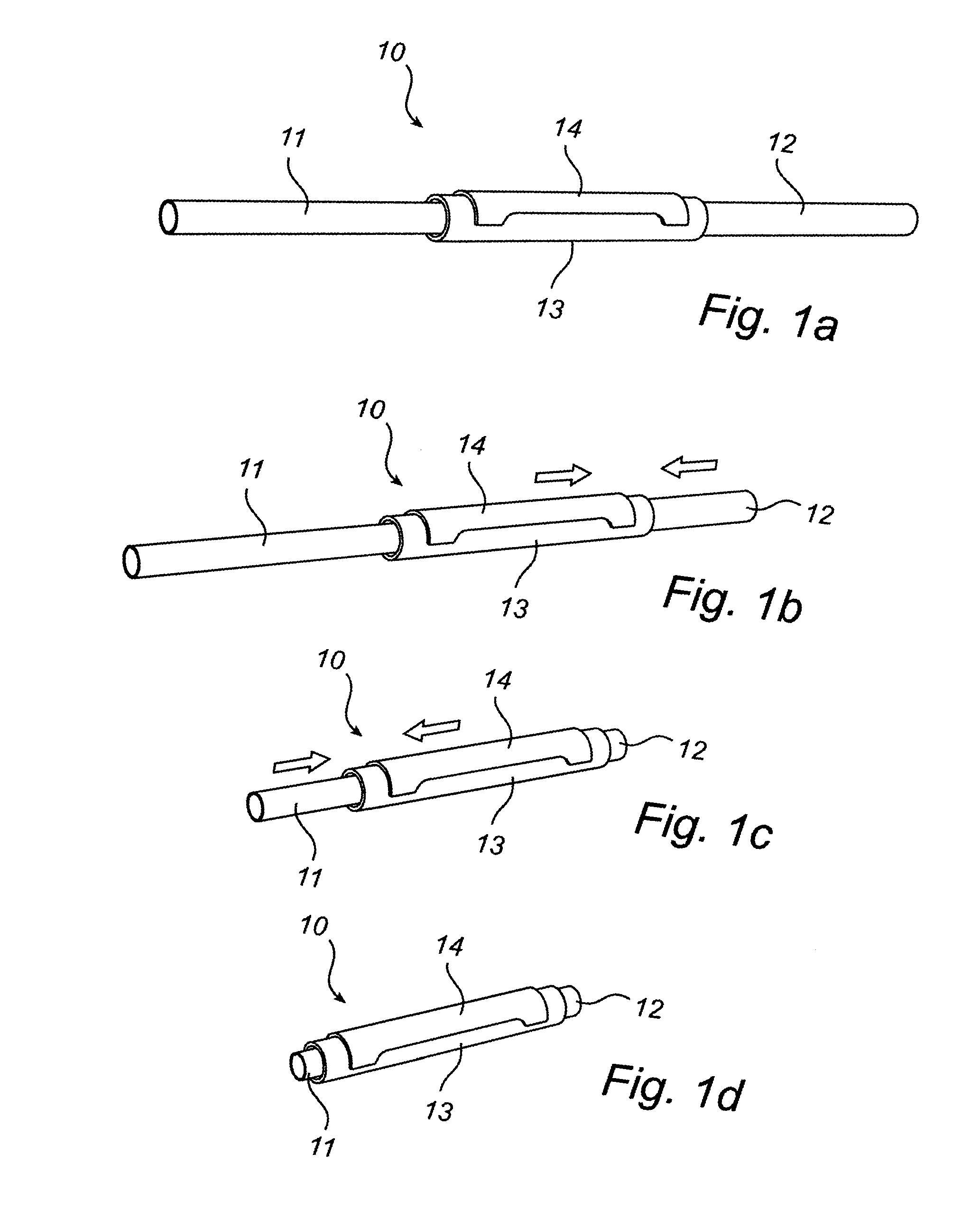

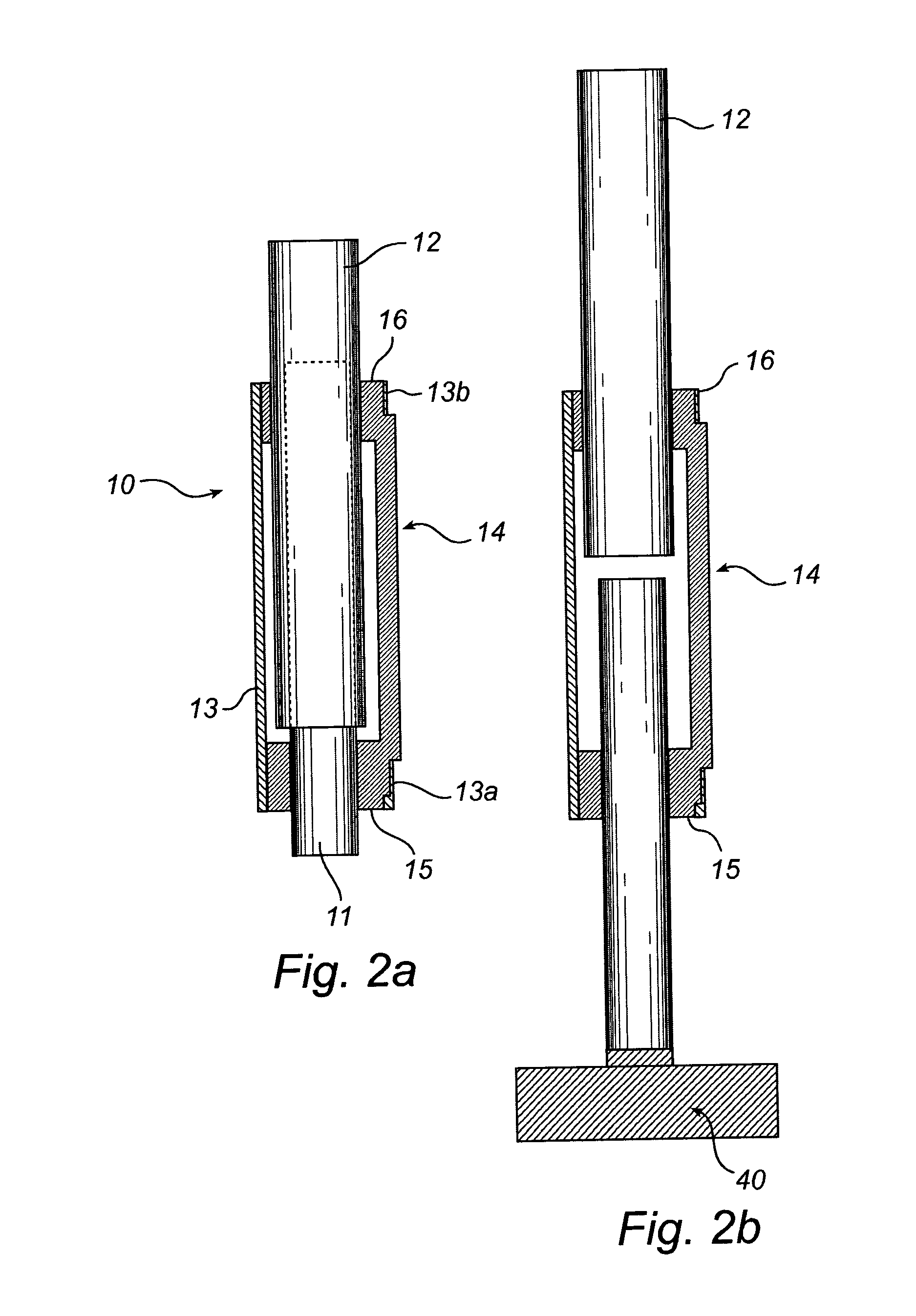

[0028]Referring to FIG. 1a), there is shown a schematic drawing of a telescopic tube for a vacuum cleaner 10 according an embodiment of the present invention. The telescopic tube 10 comprises a first inner tube 11, herein after referred to as the lower tube 11, a second inner tube 12, herein after referred to as the upper tube 12, and an outer tube 13. The upper tube 12 is arranged to be longitudinally movable inside the outer tube 13, while the lower tube 11 is arranged to be longitudinally movable inside the upper tube 12 and the outer tube 13. Hence, the outer tube 13 can encompass at least a portion of the upper tube 12 and at least a portion of the lower tube 11. In this embodiment the outer tube 13 is of about the same length as, but somewhat shorter than, the lower tube 11 and upper tube 12. Hence, the outer tube 13 contributes to a substantial part of the fully extended telescopic tube 10, while at the same time allowing the inner tubes, 11 and 12, to be almost fully retracted

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap