Method for repairing a sealing segment of a gas turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

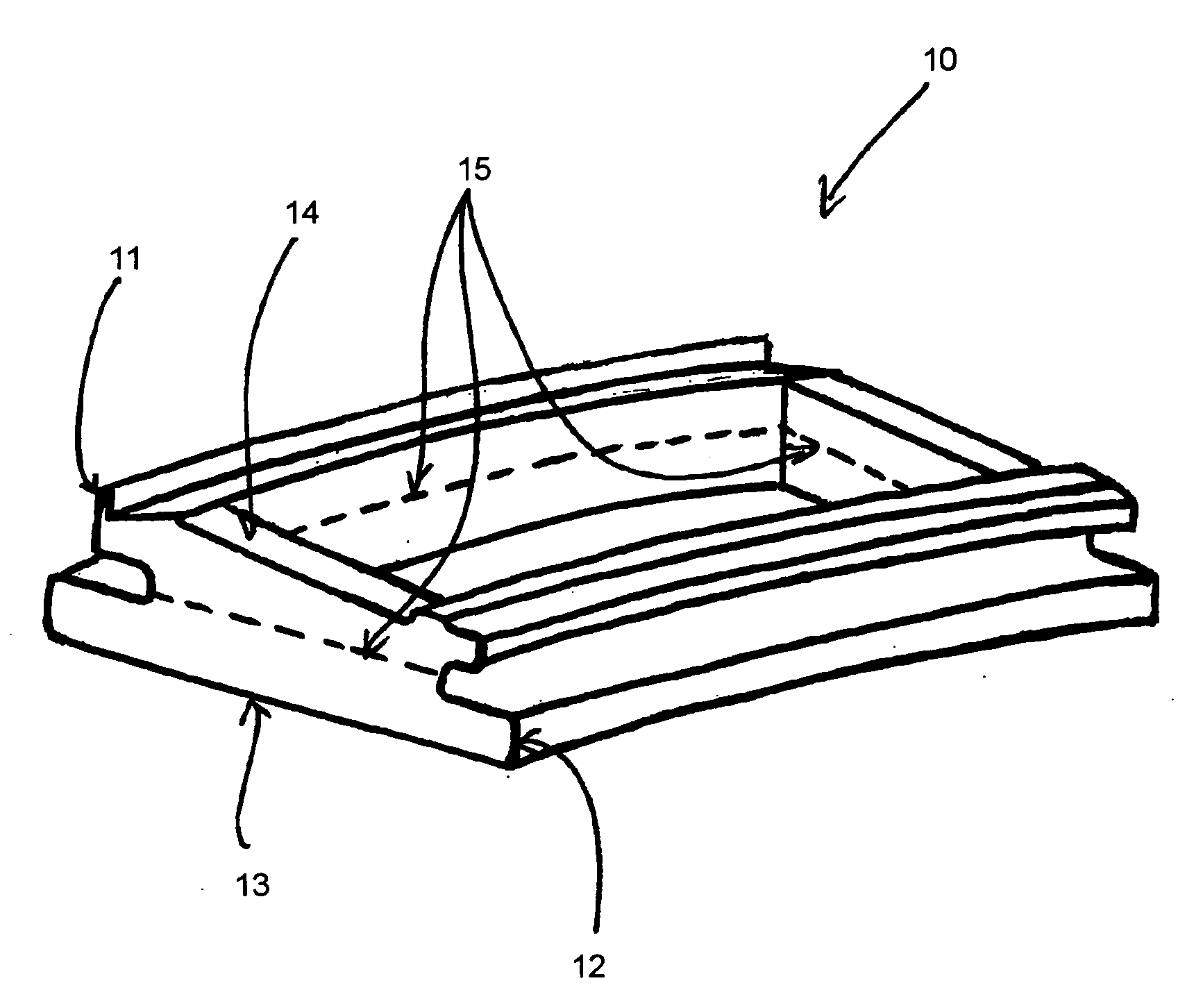

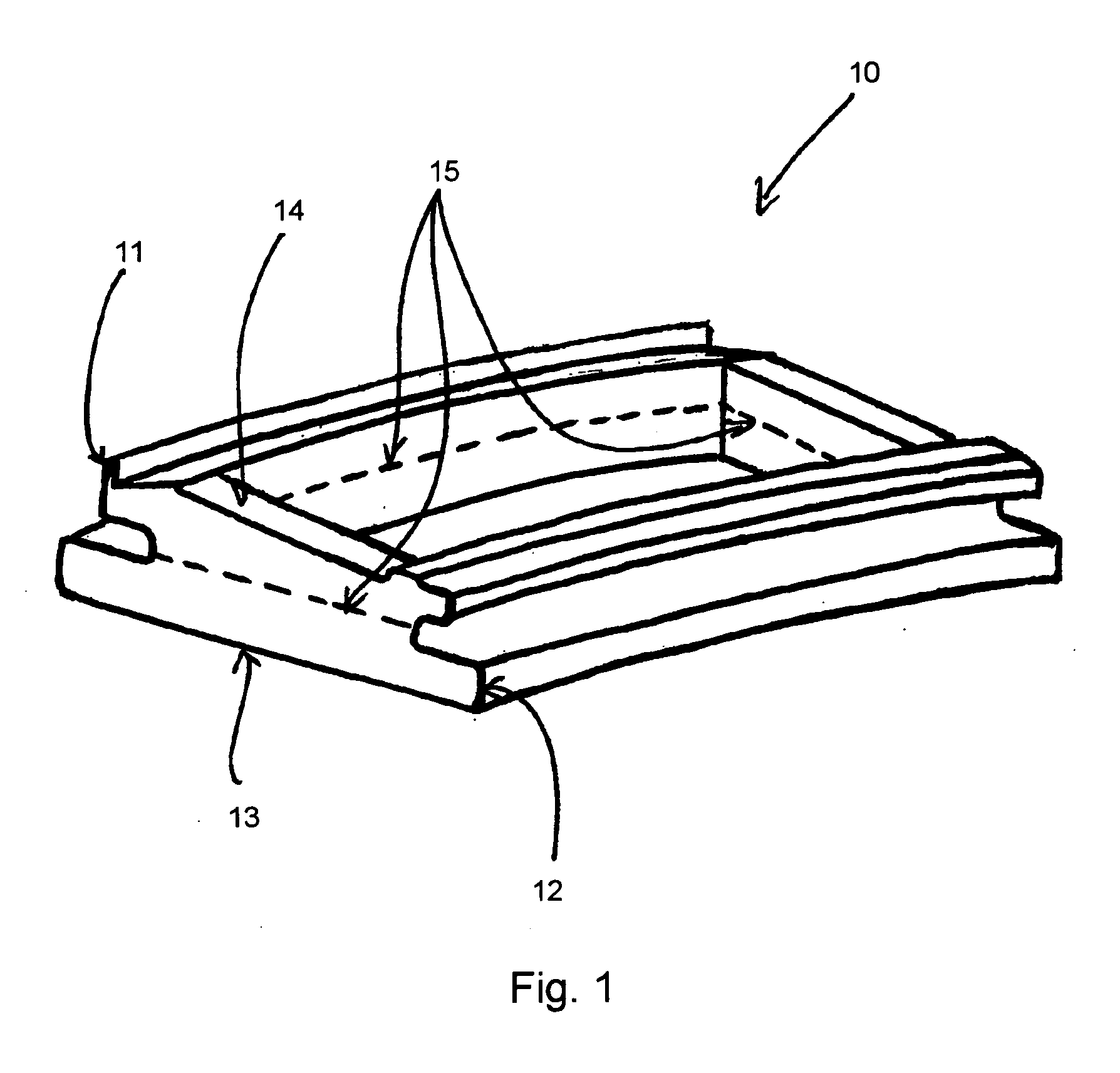

[0016]One embodiment of the present invention will now described in more detail with reference to FIG. 1.

[0017]This embodiment of the present invention is directed to a method for repairing or reconditioning sealing segments secured to the casing of a gas turbine.

[0018]FIG. 1 shows a sealing segment 10 of a gas turbine in a schematic perspective view. Sealing segment 10 includes a radially outer, frame-like holding portion 11 for a radially inner abradable portion 12. Via holding portion 11, a sealing segment 10 can be secured to a stator casing of the gas turbine.

[0019]Radially inner abradable portion 12 provides an abradable coating for contact with the tips of rotating rotor blades. Sealing segment 10 typically has a continuous closed surface 13 in the region of radially inner abradable portion 12, whereas in the region of radially outer frame-like holding portion 11, sealing segment 10 has a surface 14 which is not closed.

[0020]When such a sealing segment 10 is damaged and is to be

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap