Belt Type Continuously Variable Transmisson

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

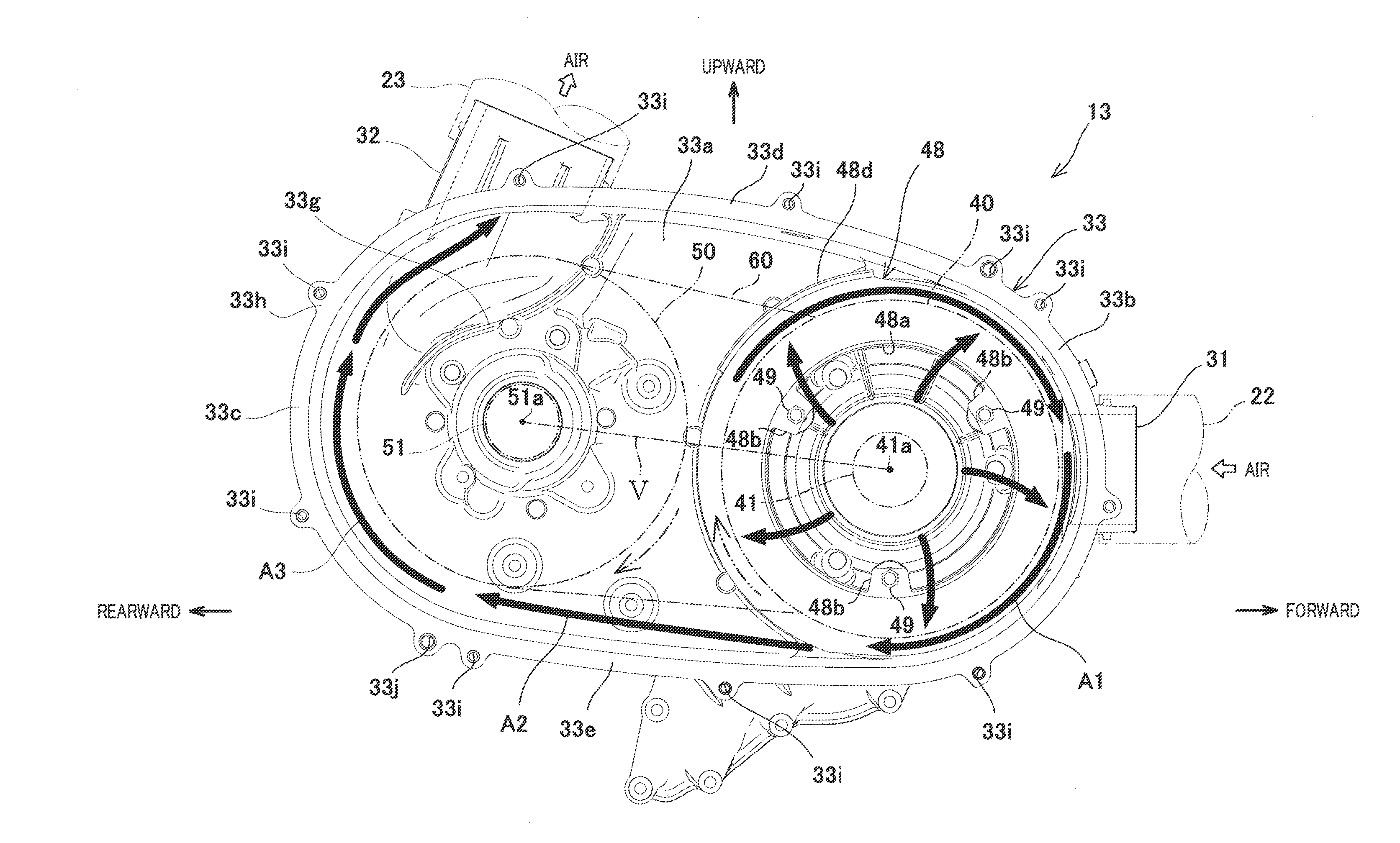

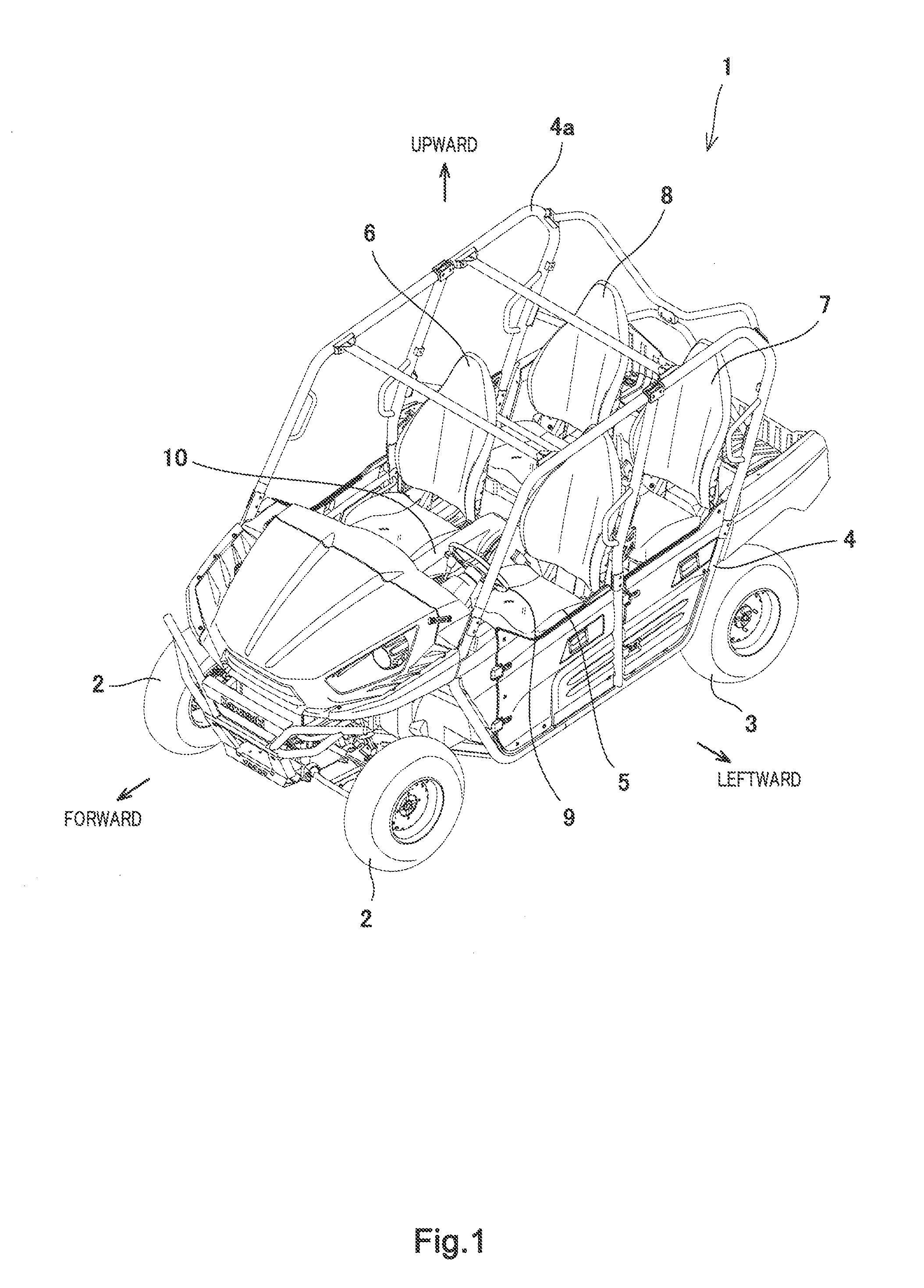

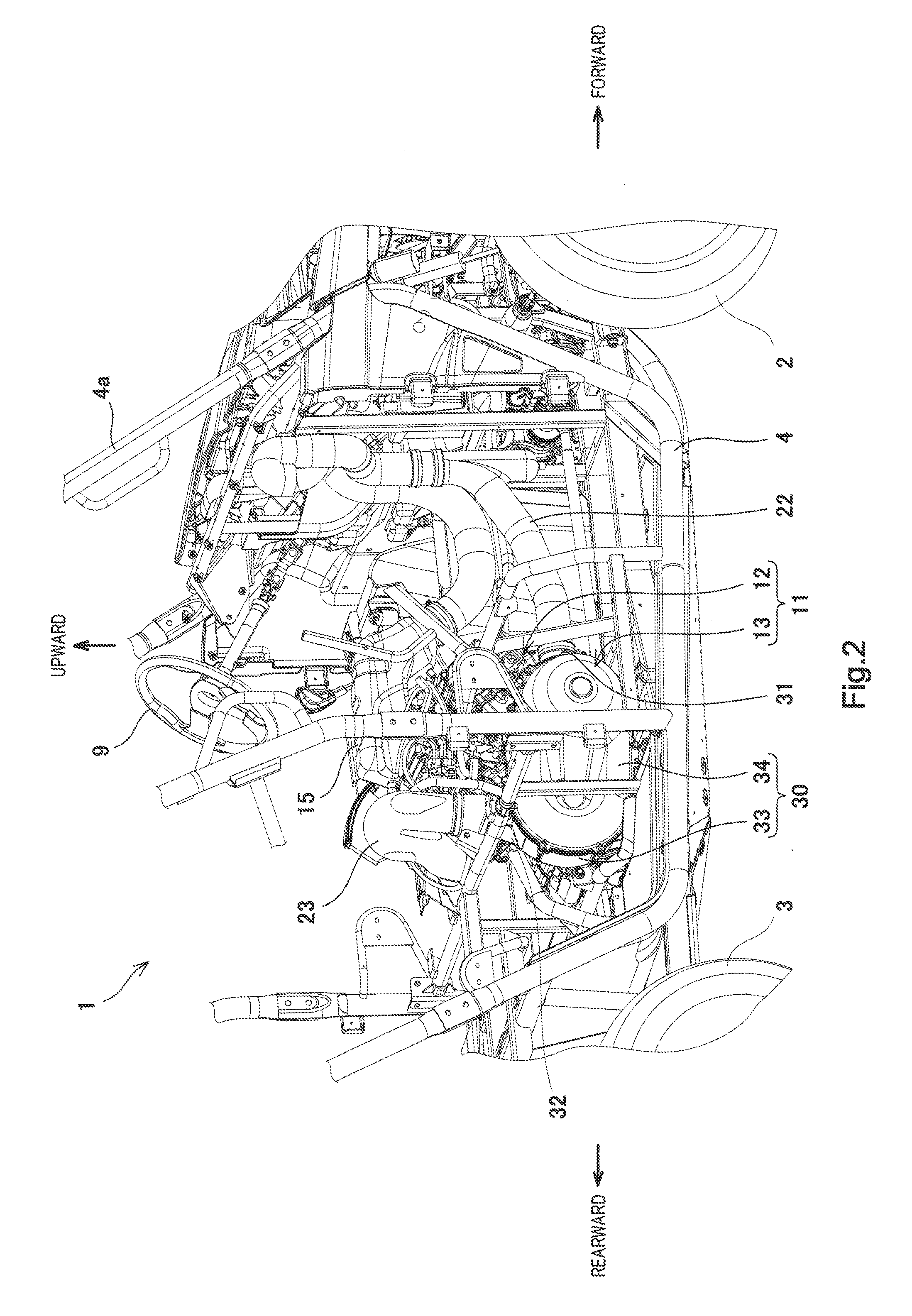

[0018]Hereinafter, an embodiment of the present invention will be described with reference to the drawings. Throughout the drawings, the same or corresponding components are identified by the same reference numerals and will not be described in repetition. The stated directions are referenced from the perspective of a driver riding in a utility vehicle.

[0019]FIG. 1 is a perspective view showing an external appearance of the utility vehicle 1 (vehicle) according to an embodiment of the present invention. For example, the utility vehicle 1 is intended for four persons and has four wheels. The utility vehicle 1 includes a pair of right and left front wheels 2, a pair of right and left rear wheels 3, a vehicle body frame 4, a driver seat 5, a passenger seat 6, a left rear seat 7, and a right rear seat 8. The front wheels 2 are suspended from the front portion of the vehicle body frame 4, while the rear wheels 3 are suspended from the rear portion of the vehicle body frame 4. The four seats

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap