Self-loosening capsule

a self-loosening, capsule technology, applied in the direction of steering column, steering parts, vehicle components, etc., can solve the problem of unsuitably high load required for breaking away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

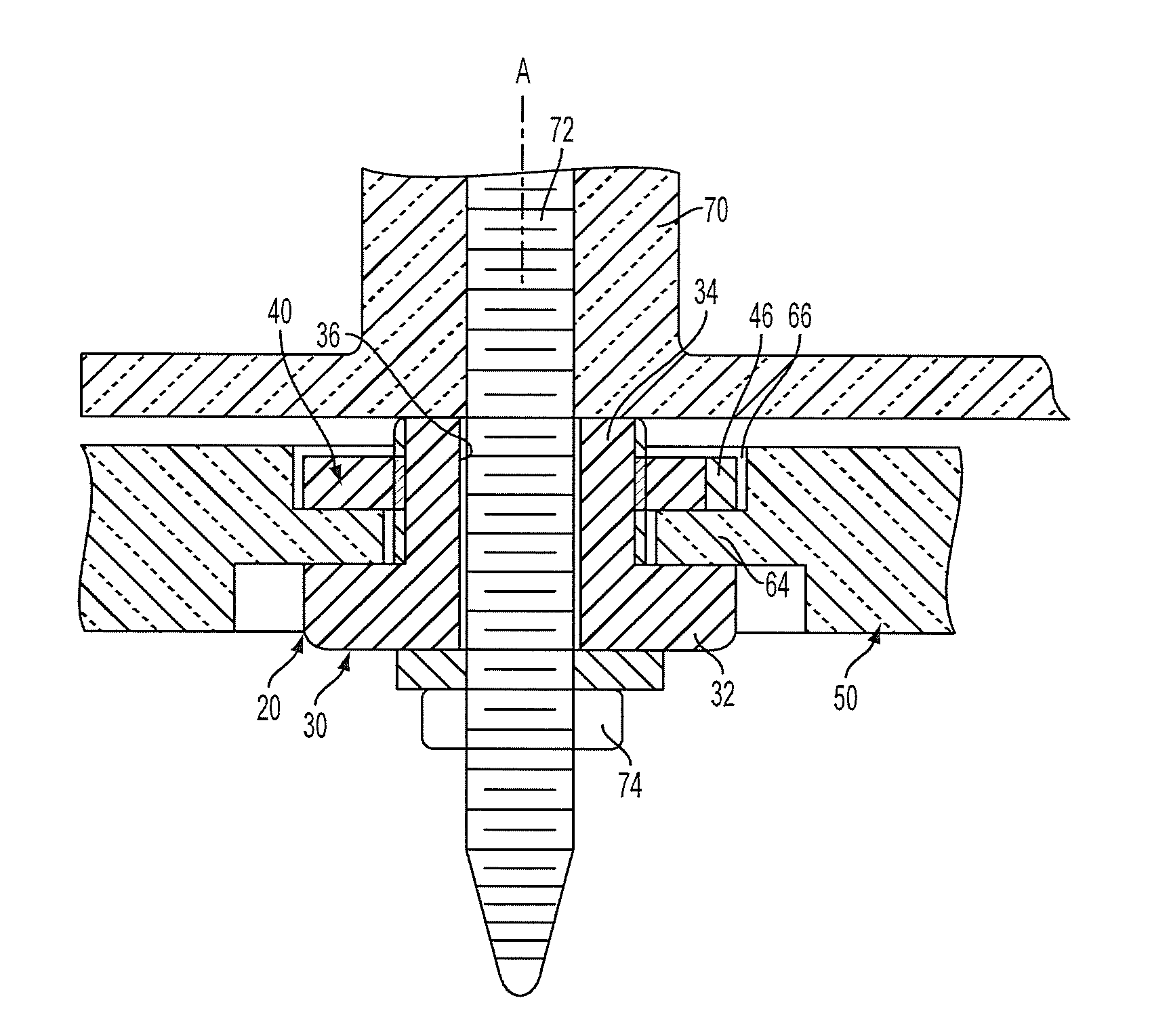

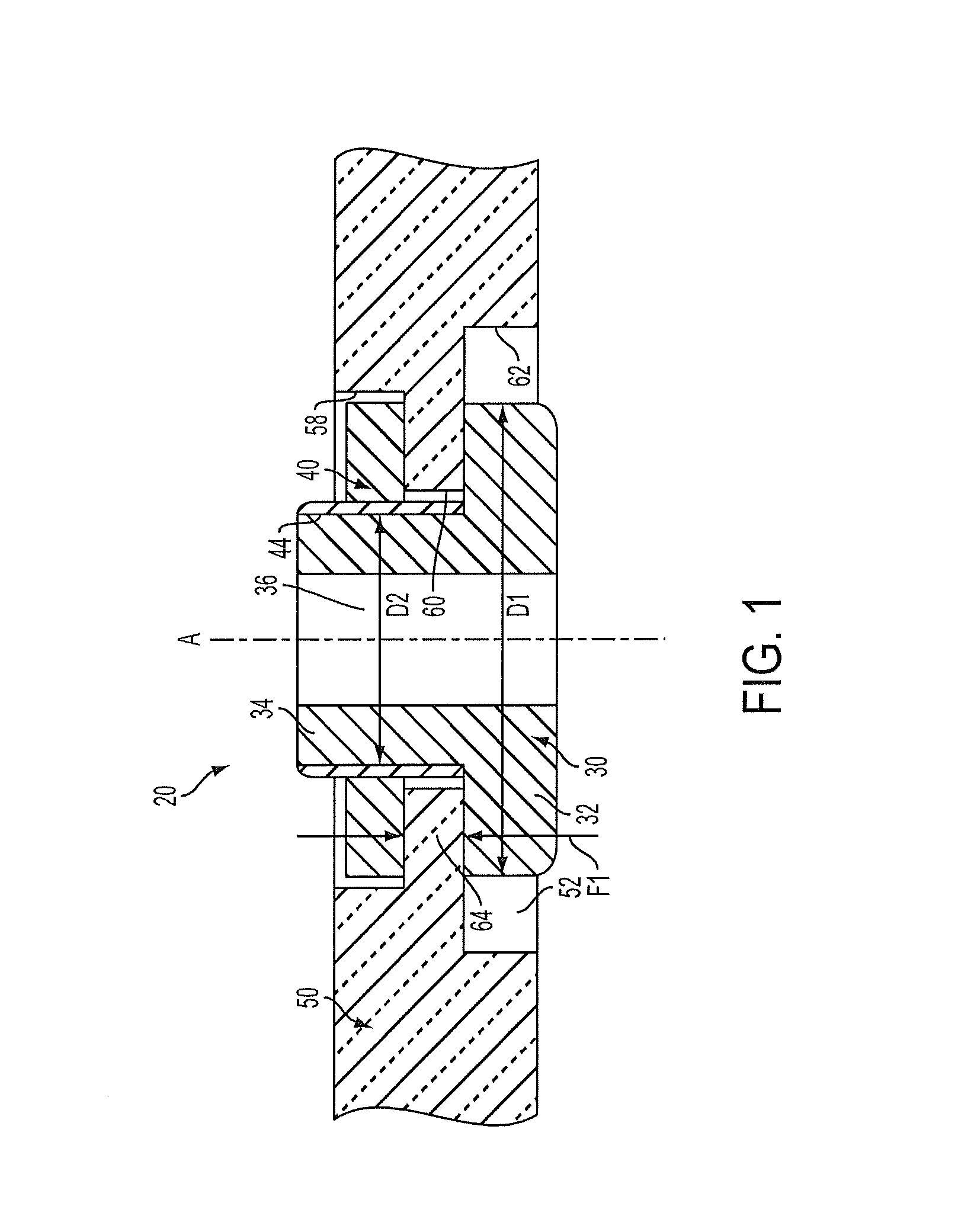

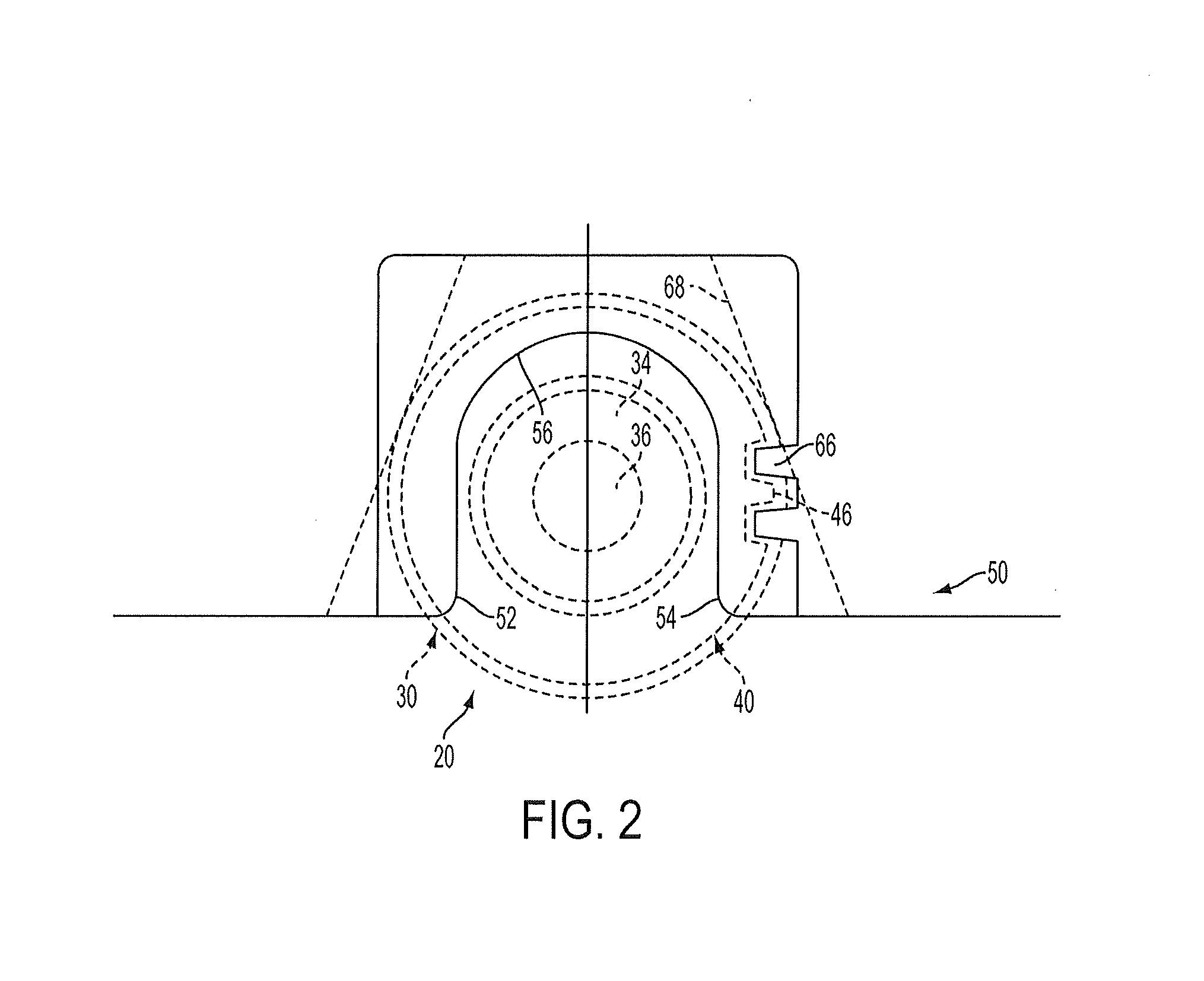

[0015]Referring now to the Figures, where the invention will be described with reference to specific embodiments, without limiting same, FIG. 1 is a cross section of a self-loosening capsule assembly 20 comprising a capsule 30 and capsule nut 40. The self-loosening capsule assembly 20 is installed in a mounting bracket 50 of a steering column (not shown). The mounting bracket 50 is configured to mount the steering column in a vehicle.

[0016]In an exemplary embodiment, the capsule 30 is round in shape and includes a head 32 and body 34. The head 32 has a first outer diameter D1 and the body has a second outer diameter D2. The first outer diameter is greater than the second outer diameter. The head 32 is generally disk shaped.

[0017]The body 34 extends from the head 32. In an exemplary embodiment, the body 34 extends along a first axis ‘A’. An outer surface of the body 34 includes an external thread. A central bore 36 extends through the head 32 and body 34 along the axis ‘A’. The central

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap