Can Comprising a First, Dispense Opening and Second, Vent Opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

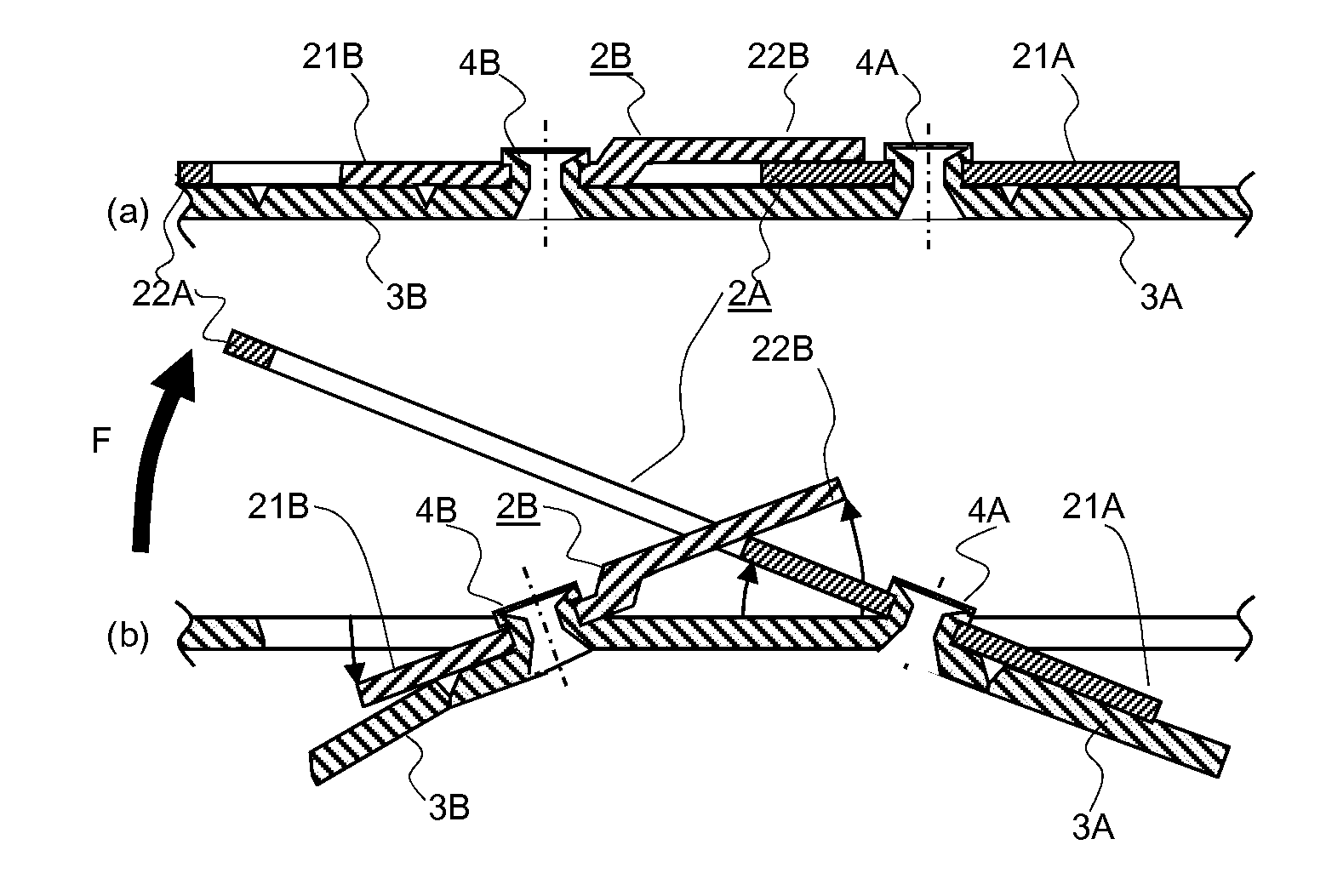

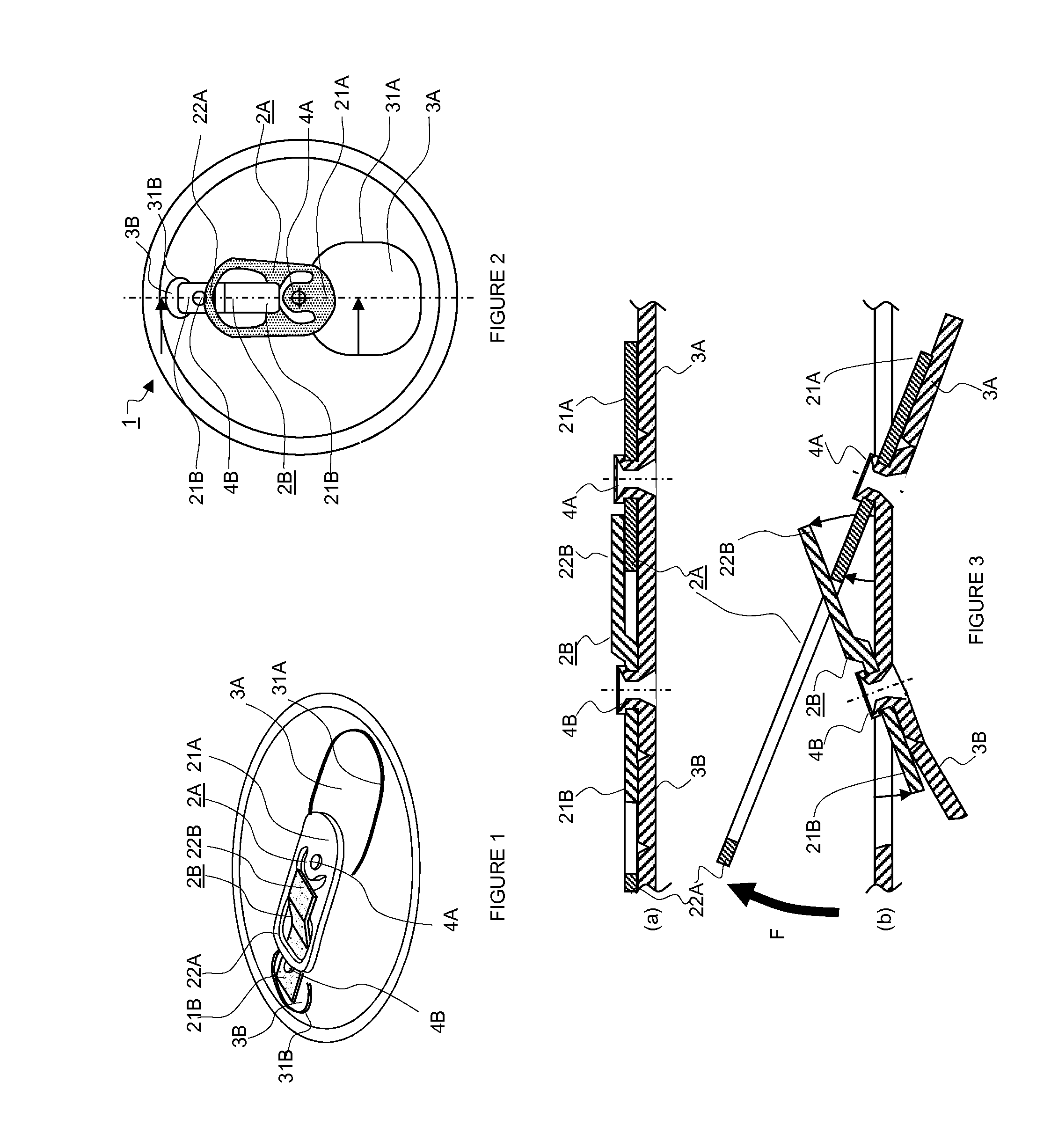

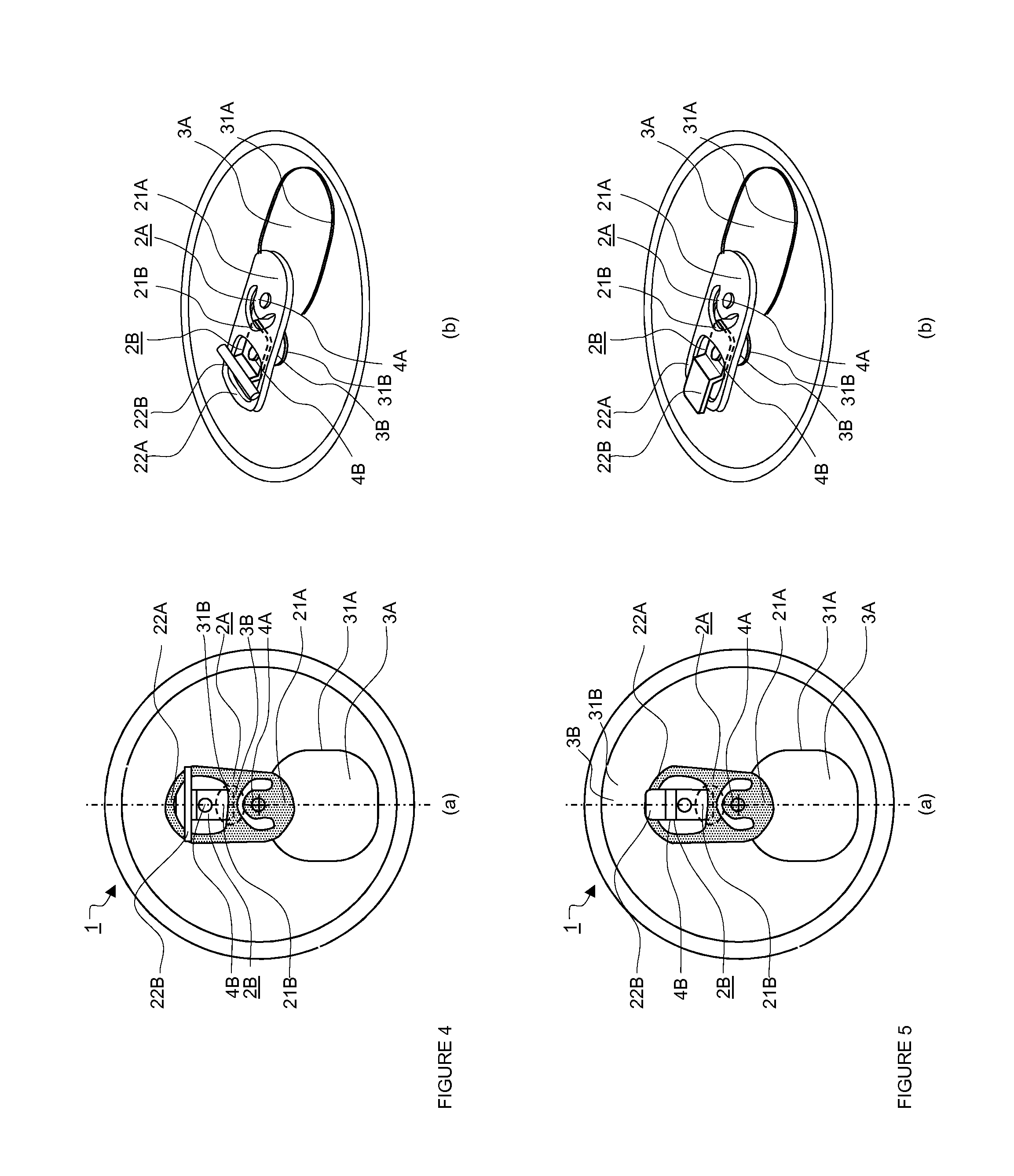

[0024]As can be seen in FIGS. 1, 2, 4, and 5, a can according to the present invention comprises a top end like traditional cans available in shops to date, with a dispense area (3A) defined on said top end by a first score line (31A), and a pull tab (2A) coupled to the top end by a first rivet (4A). The pull tab (2A) comprises a puncturing end (21A) overlapping the dispense area and an opposite actuating end (22A) which, upon lifting away from the plane of the can top end presses the puncturing end (21A) against the dispense area, breaking the score line and pushing the dispense area into the can, thus opening the dispense aperture. It is of course much preferable that upon opening the dispense aperture (13A), neither the pull tab (2A) nor the dispense area (3A) are separated from the can top end. This can be achieved either by not closing the path formed by the first score line (31A) or by providing a portion of said first line with a shallower score (i.e., less deep) than the rest o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap