Method of load shedding in aircraft and controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The embodiment according to the present invention will be described below with reference to the drawings.

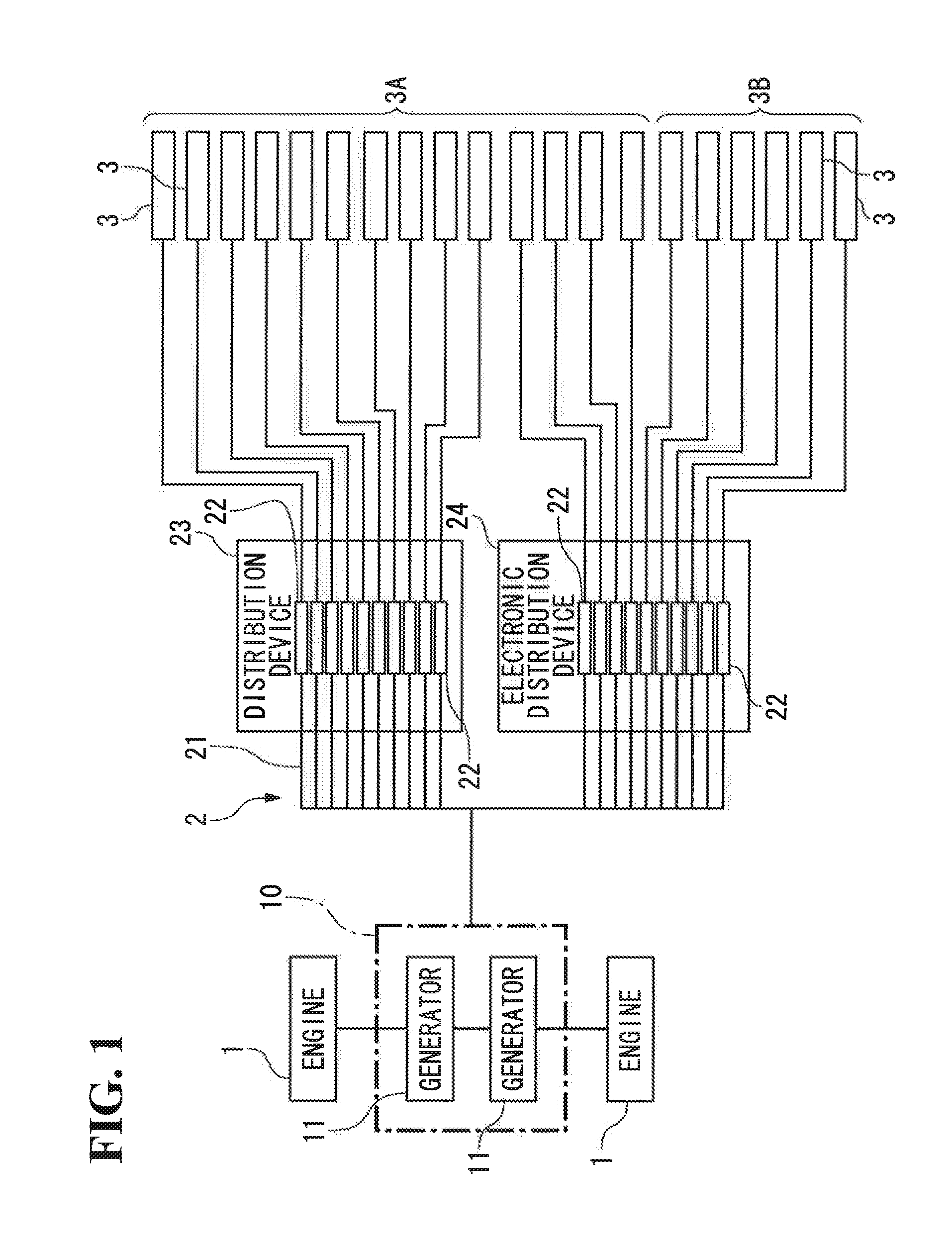

[0044]An aircraft according to the present embodiment includes, as shown in FIG. 1, two engines 1 and 1, and generators 11 and 11 provided in the engines 1 and 1, respectively.

[0045]Each of the generators 11 and 11 generates AC power from part of the rotation of the engine 1 as a power source. The two generators 11 and 11 operate in parallel, forming one power supply 10.

[0046]The power generated by these generators 11 and 11 is supplied to a large number of devices (electrical loads) 3 constituting a device group, through the power supplying system 2. Note that only some of the large number of devices 3 are shown.

[0047]Each of the generators 11 and 11 has a power-generation capacity of W (under normal operation conditions). The generators 11 and 11 form the power supply 10 having a power-generation capacity of 2 W.

[0048]These generators 11 and 11 generate the power up to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap