Adaptor Tee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0043]Embodiments will be described in detail with reference to the accompanying drawings. The following description of the embodiments is given only for the purpose of illustration and is not to be taken in a limiting sense.

[0044]The drawings are to be regarded as being schematic representations only, and elements in the drawings are not necessarily to scale with each other. Rather, the representation of the various elements is chosen such that their function and general purpose become apparent to a person skilled in the art.

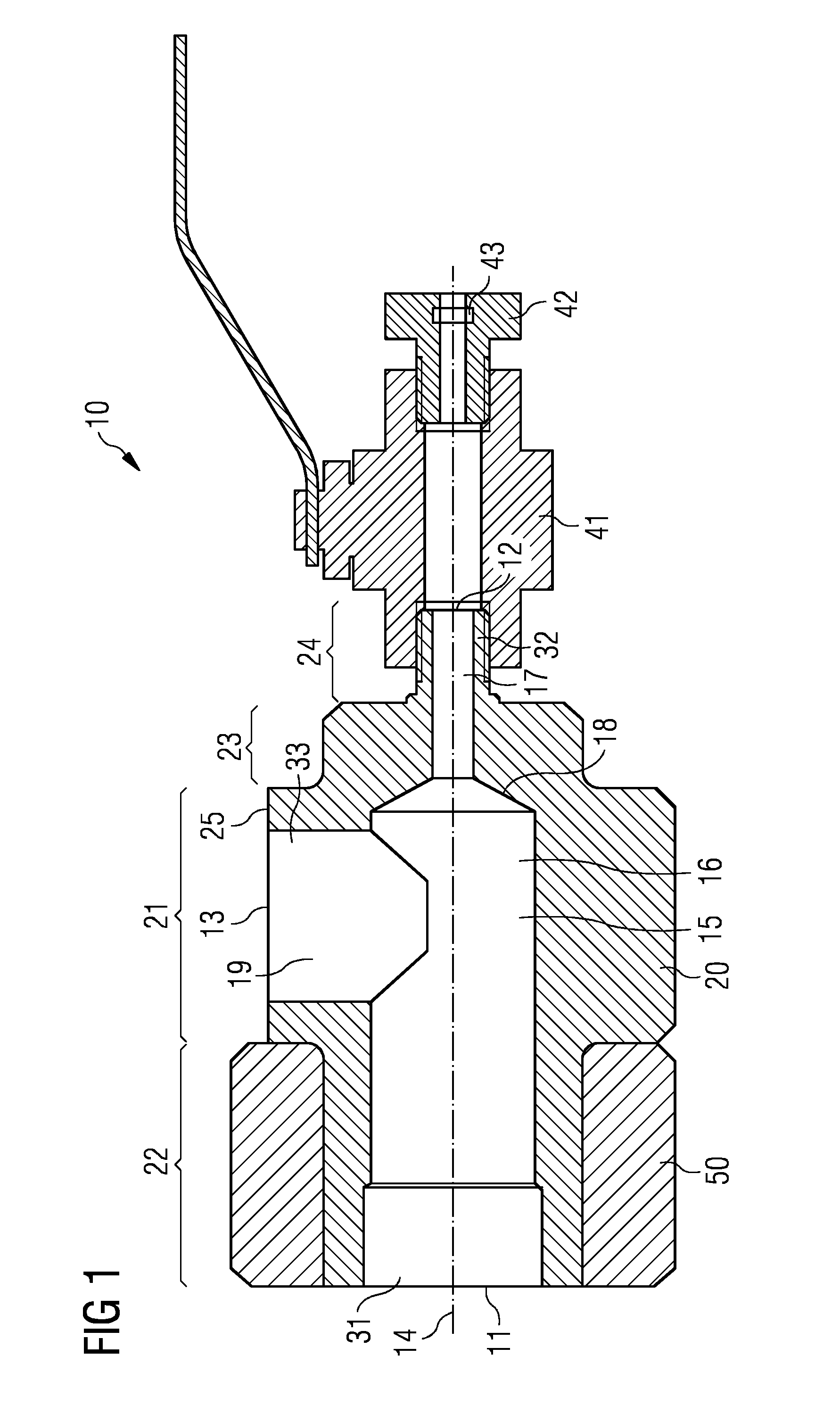

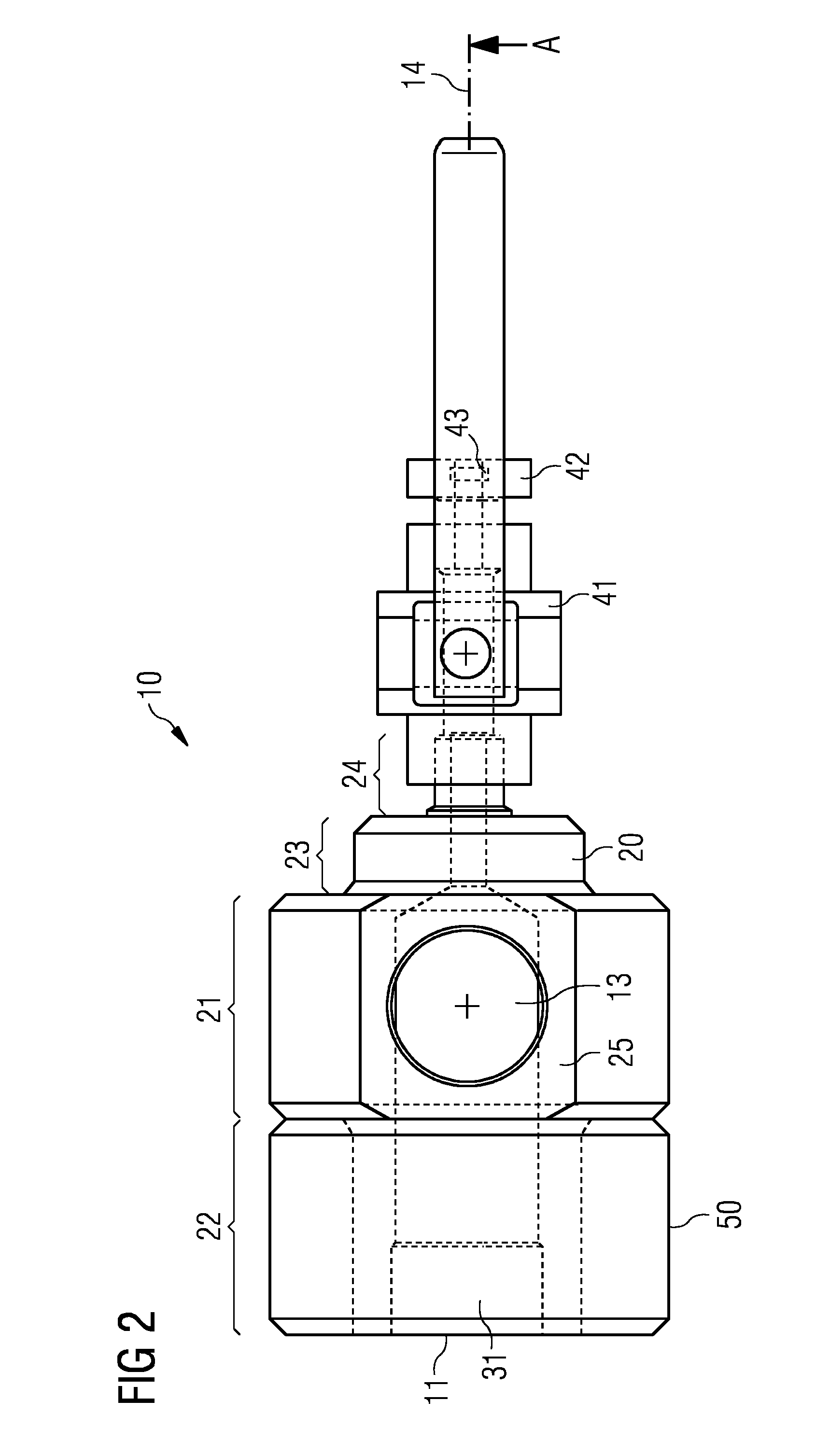

[0045]FIG. 1 is a schematic drawing showing a sectional side view of an adaptor tee 10 according to an embodiment. The adaptor tee 10 includes a main body 20 that is made of a single piece of plastic material. The main body 20 has a cylindrical shape that extends along the axial direction or longitudinal axis 14. At a first end, the main body 20 has a first inlet opening 11. At a second opposite end, the main body 20 has a first outlet opening 12. Between the inle

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap