Light Assembly and Alignment Device

a technology of alignment device and assembly, which is applied in the direction of lighting device details, lighting support devices, lighting and heating apparatus, etc., can solve the problems of difficult to find blind holes and problematic installation of fixtures, and achieve quick and accurate assembly installation, selective raising and lowering, and increased heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]While the invention will be described in connection with one or more preferred embodiments, it will be understood that it is not intended to limit the invention to those embodiments. On the contrary, it is intended to cover all alternatives, modifications and equivalents as may be included within the spirit and scope of the invention as defined by the appended claims.

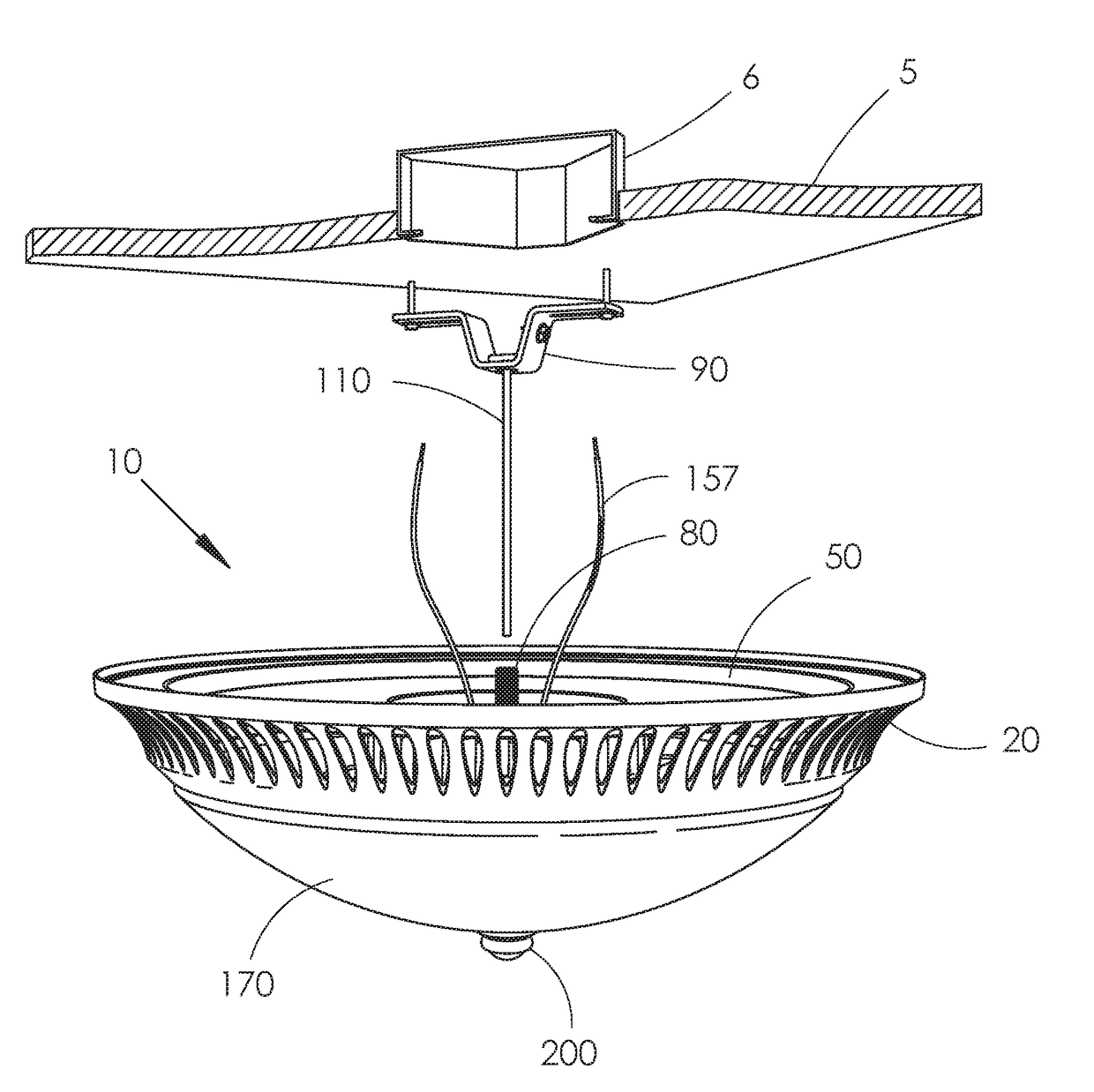

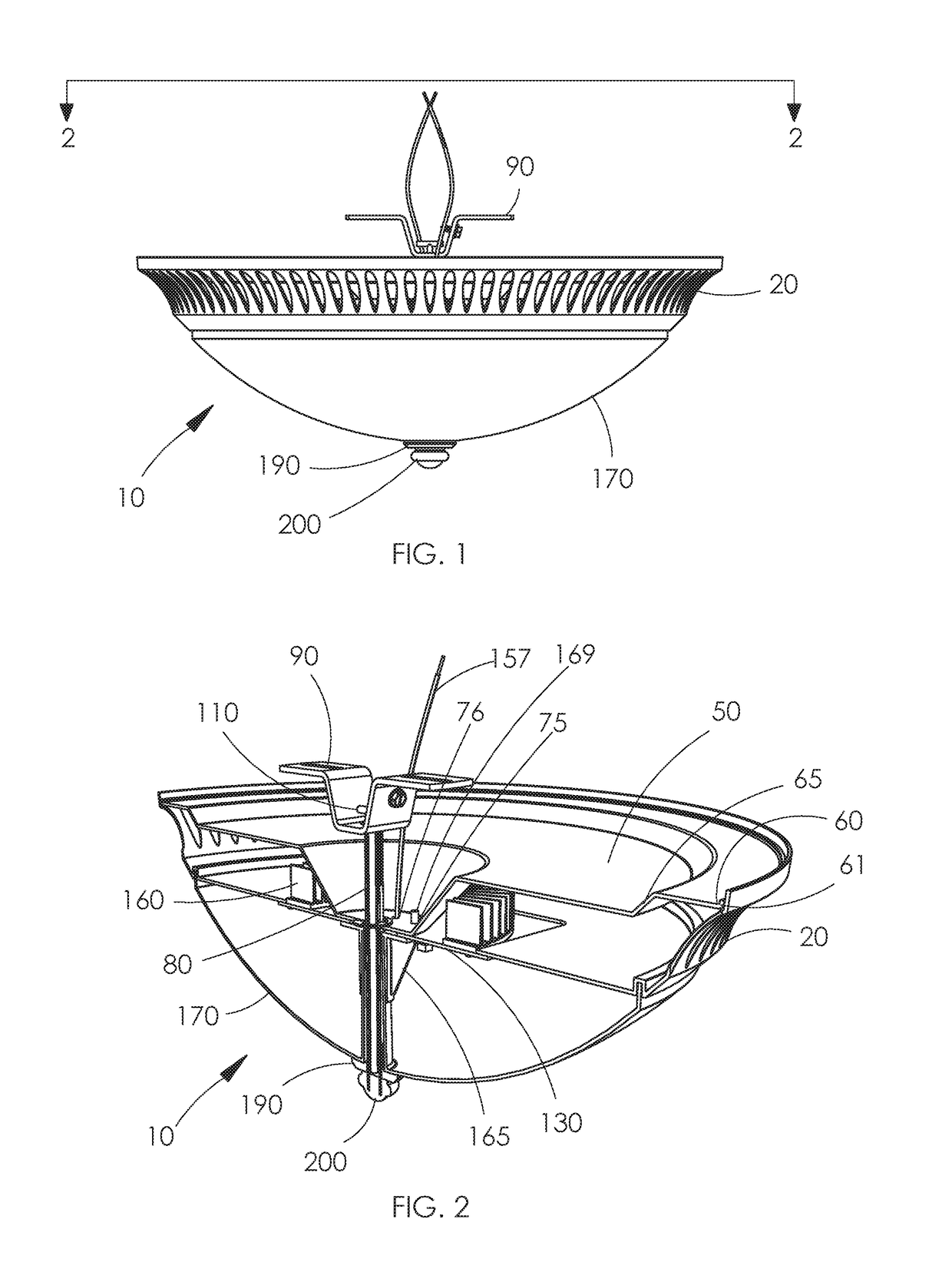

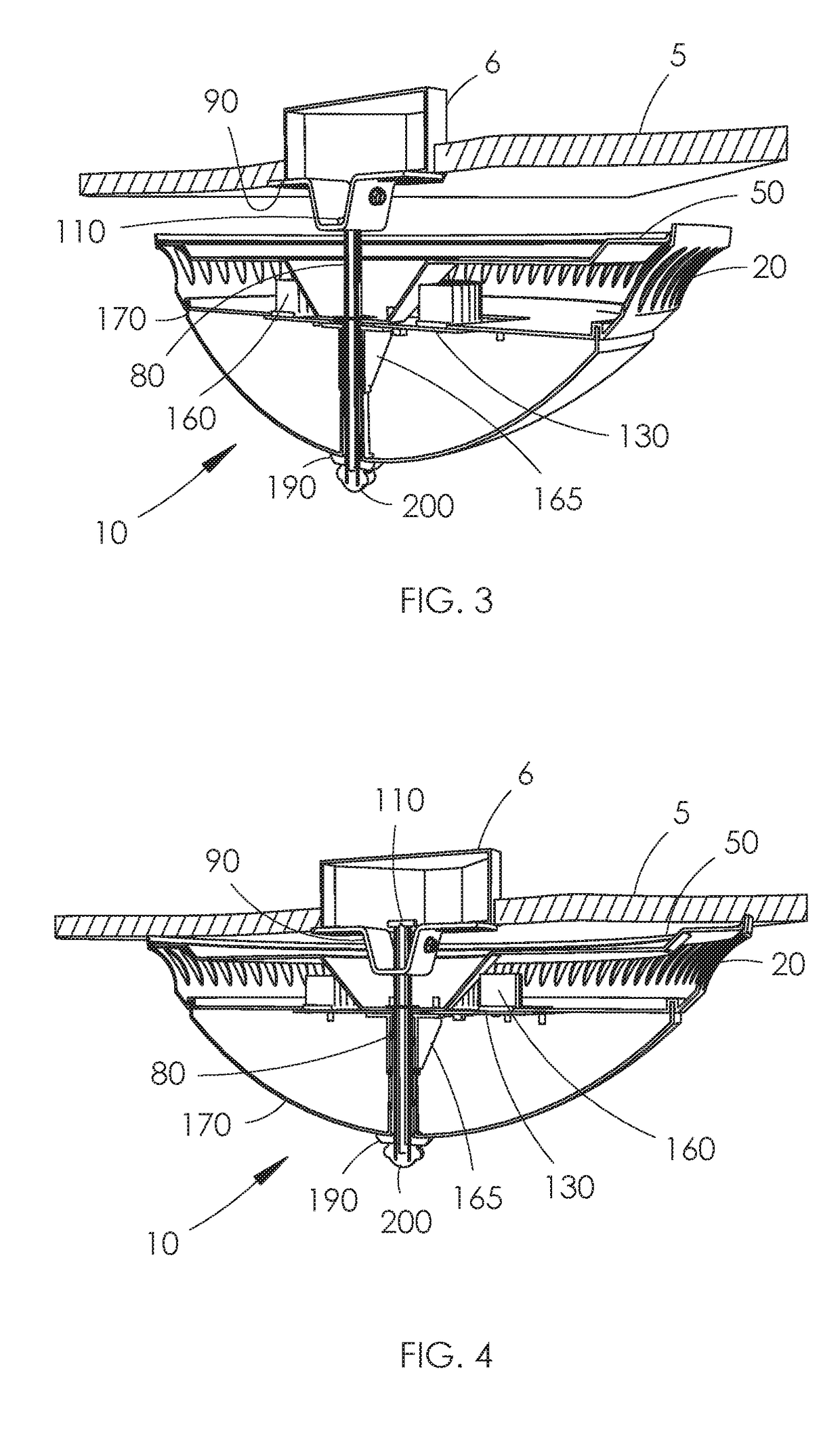

[0042]Turning now to FIGS. 1-6, it is seen that a preferred embodiment of the present invention is illustrated. A light assembly 10, or simply assembly or fixture, is shown in relation to a ceiling 5 adjacent the recessed electrical box 6. The assembly 10 has a spacer 20, a lid 50, a rod 80 a bracket 90, a guide 110, electronics 130, a heat sink 160, a lifter 165, a cover 170, a washer 190 and a nut 200. Each of these components are described in detail below. It is appreciated that these components are not all required components for each inventive aspect of the present invention.

[0043]The spacer 20 is best seen in F

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap