Twist drill with unequal flute spacing and unequal relief angles

a drill bit and flute technology, applied in the field of rotary cutting tools, can solve the problems of rotating drill bit vibrations that cause “chatter” recur periodically, more complex geometrical design, and more difficult manufacturing of twist drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

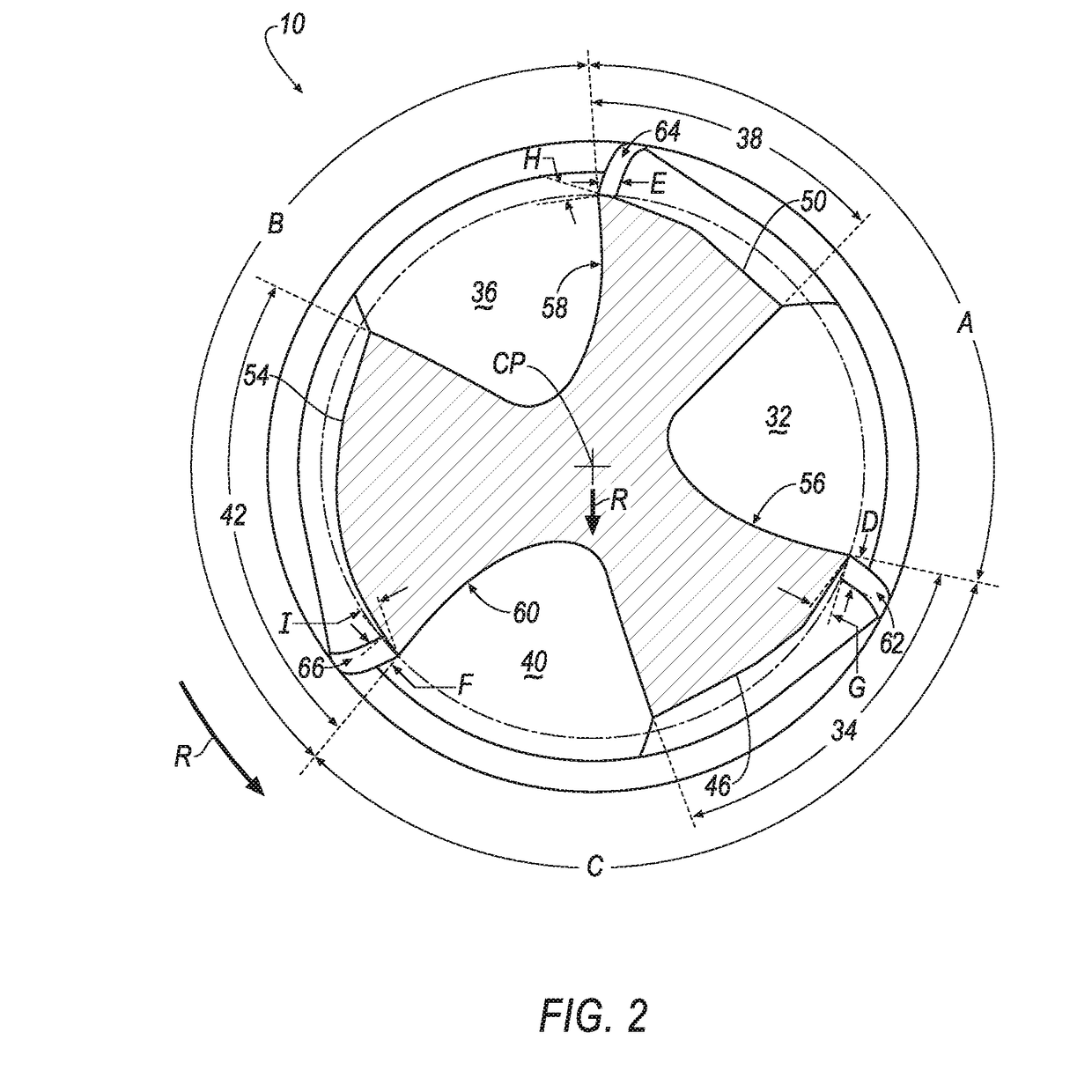

[0020]In one aspect of the invention, the invention is directed to a rotary cutting tool having at least one helical flute. For purposes of explanation, a twist drill will be described herein with the understanding that the invention is applicable to other cutting tools having one or more helical flutes, such as, for example, taps and reamers. In addition, a cutting tool having three helical flutes is described herein. However, it will be appreciated that the invention is not limited by the number of helical flutes, and that the invention can be practiced with a cutting tool having two or more helical flutes.

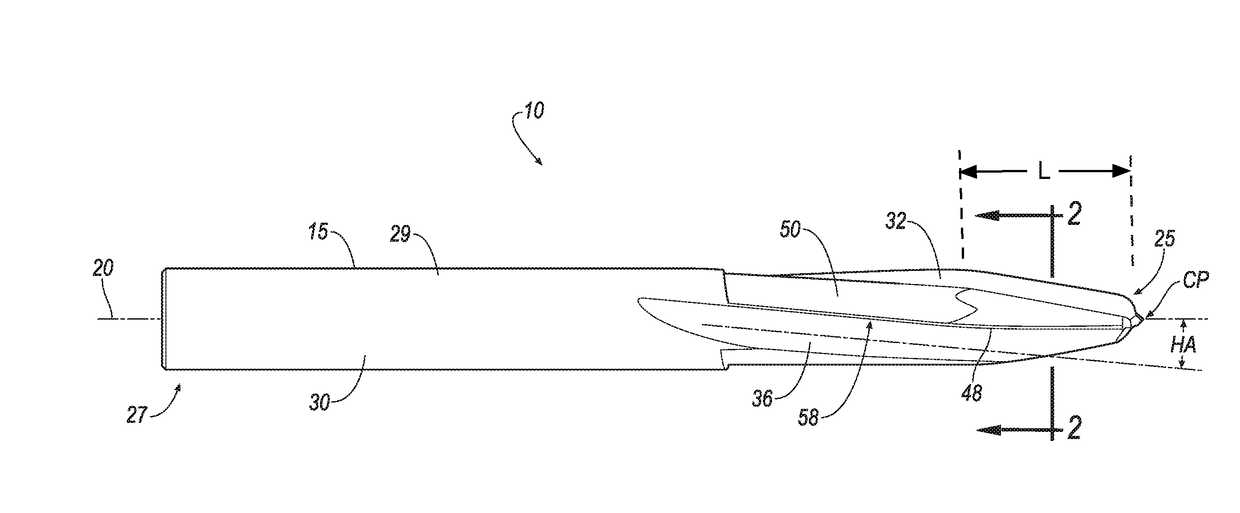

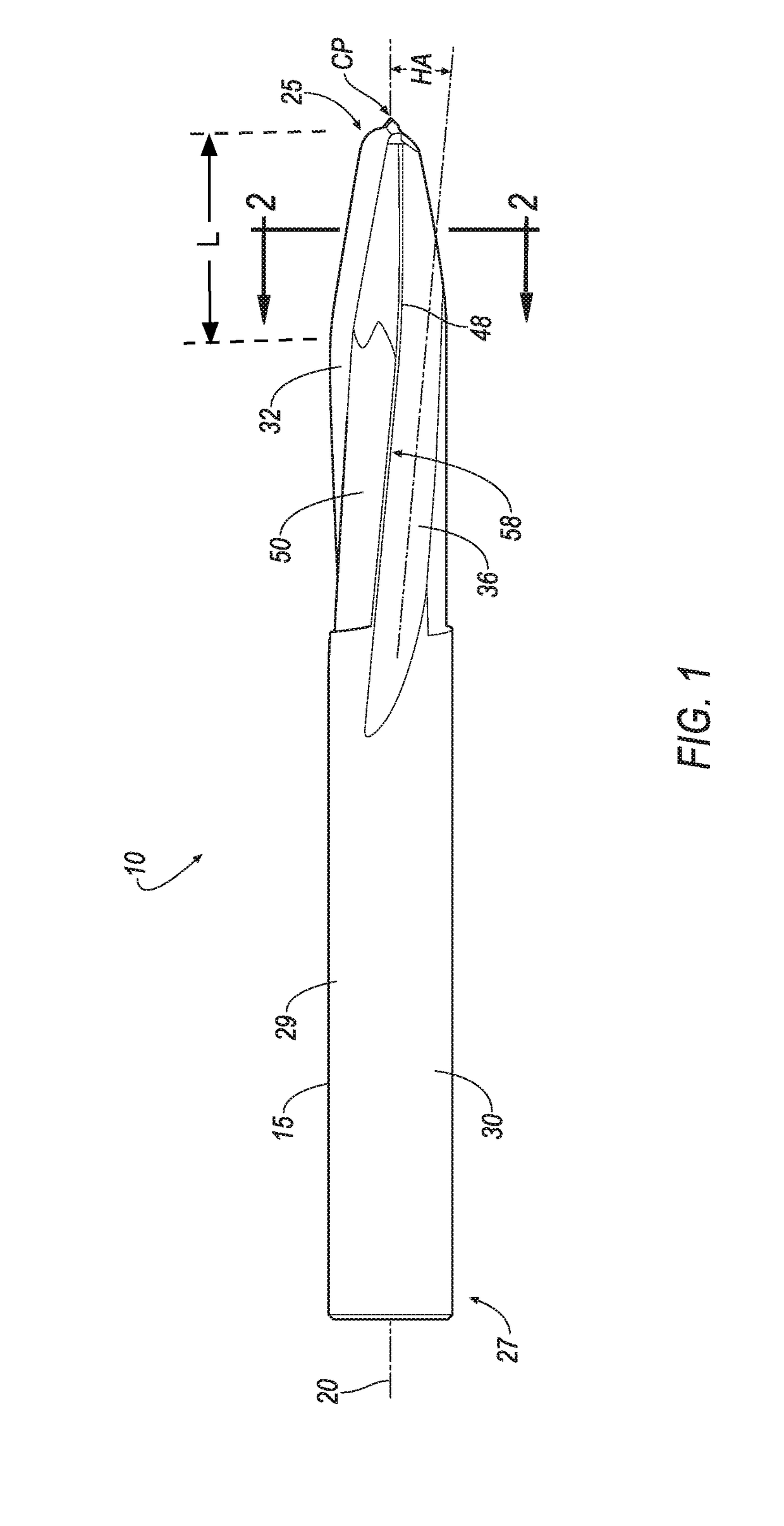

[0021]Referring to FIGS. 1 and 2, there is shown a cutting tool 10 which, for purposes of description herein, will be referred to as a monolithic twist drill, having a shaft 15 with a longitudinal axis 20. “Monolithic”, as used herein, does not mean that the rotary cutting tool must be made from a single material. The rotary cutting tool may indeed be fabricated from a combination

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap