Torsion spring fixation in automatic drug delivery device

a technology of automatic delivery and twisting spring, which is applied in the direction of intravenous devices, automatic syringes, syringes, etc., can solve the problems of high production cost of poor rotational tolerance of hooked spring ends, and high cost of producing helical torsion springs with hooked ends. , to achieve the effect of reducing or eliminating at least one drawback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]When in the following relative expressions, such as “upper” and “lower”, are used, these refer to the appended figures and not necessarily to an actual situation of use. The shown figures are schematic representations for which reason the configuration of the different structures as well as their relative dimensions are intended to serve illustrative purposes only.

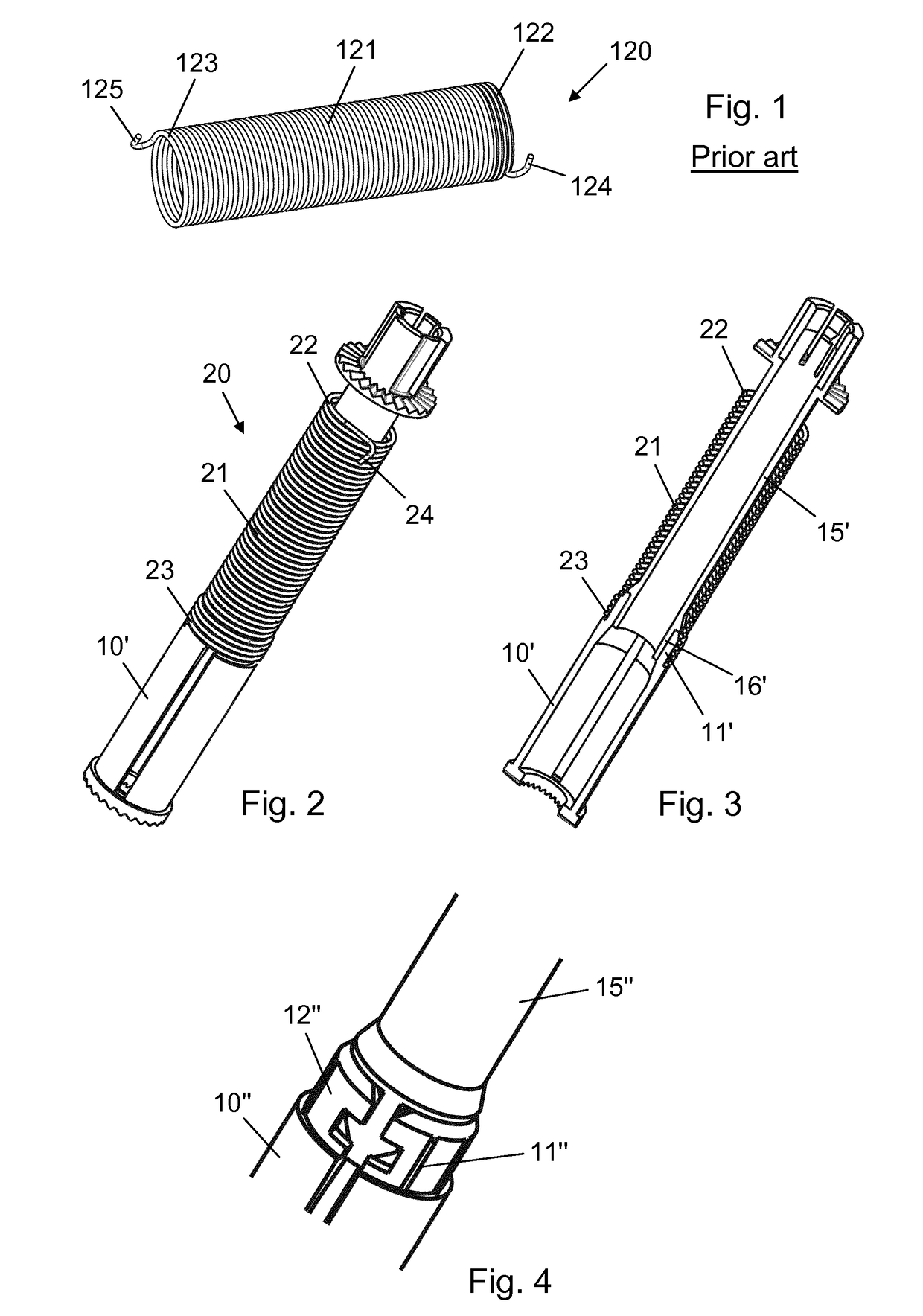

[0051]FIG. 1 shows a torsion spring 120 as conventionally used in the art of torsion spring based automatic injection devices. The torsion spring 120 comprises a helically coiled body 121 which extends longitudinally between a proximal end portion 122 and a distal end portion 123. The proximal end portion 122 terminates in a proximal (open) hook 124 while the distal end portion 123 terminates in a distal (open) hook 125. In conventional applications the proximal hook 124 is attached to a proximal receiving section which is stationary with respect to the injection device housing, and the distal hook 125 is attached to a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap