Integrated Modular Integrated Circuit Test Fixture and Handler Interface

a technology of integrated circuits and test fixtures, applied in the direction of electrical measurement instruments, measurement devices, instruments, etc., can solve the problems of disassembly and reassembly being the source of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

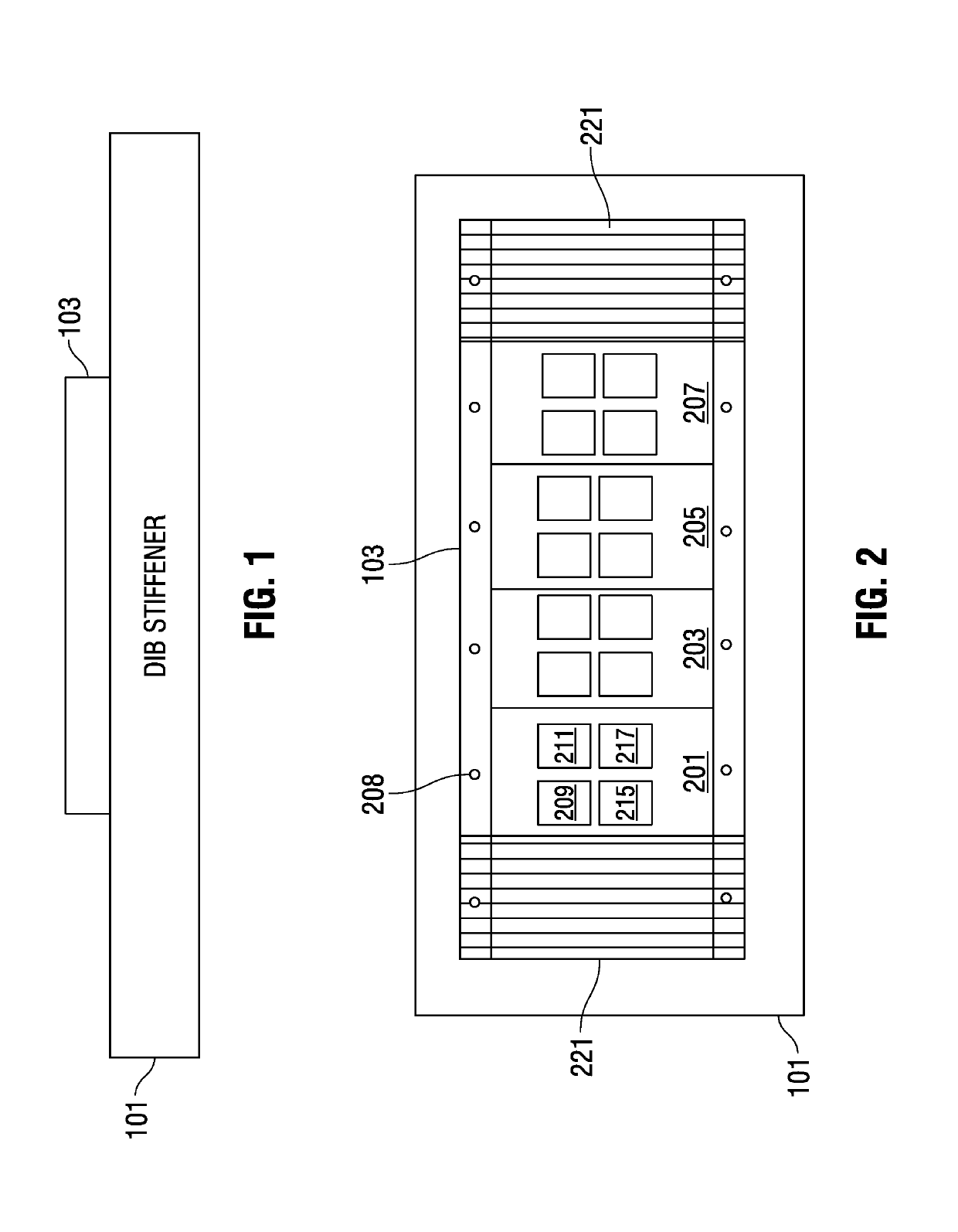

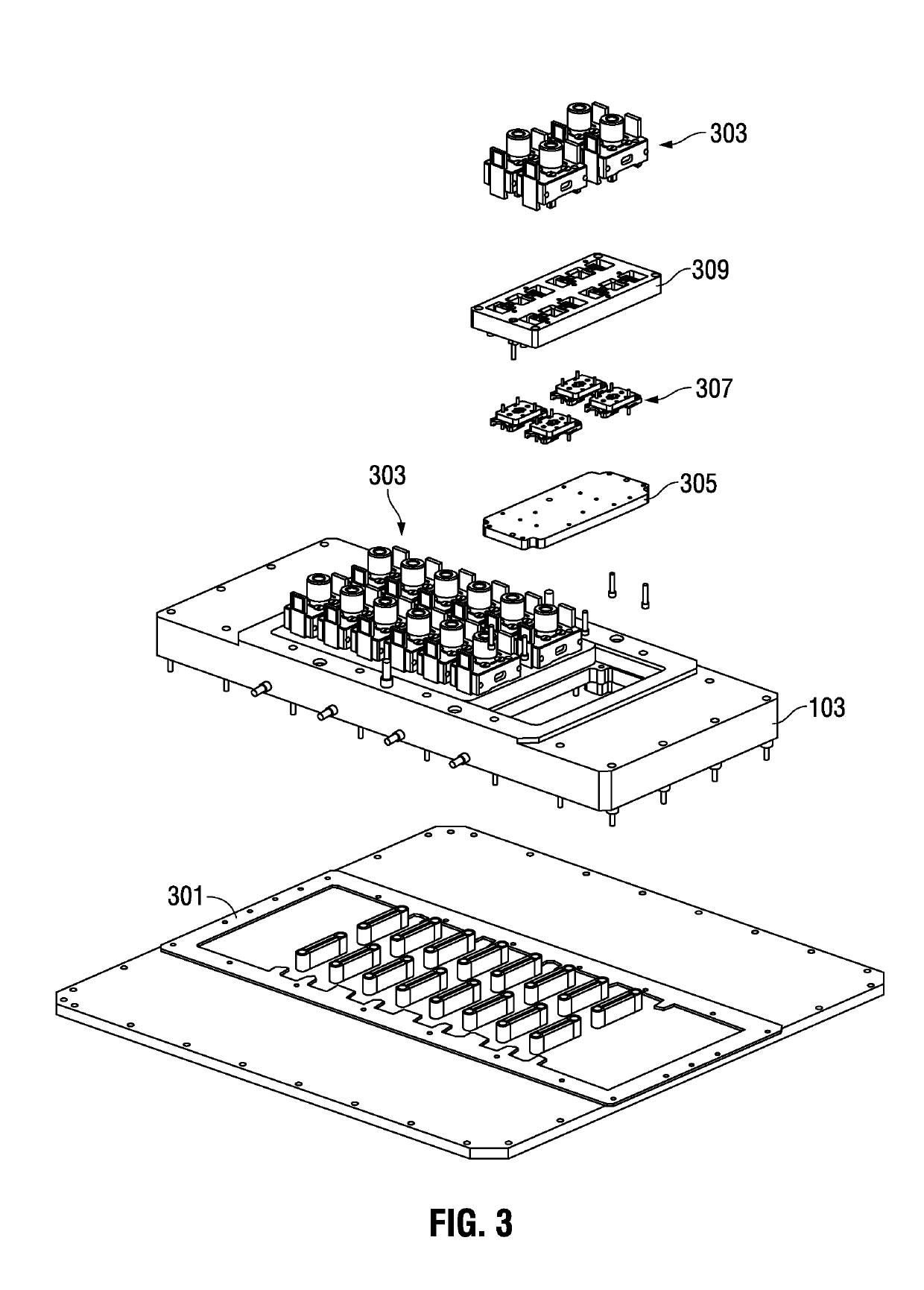

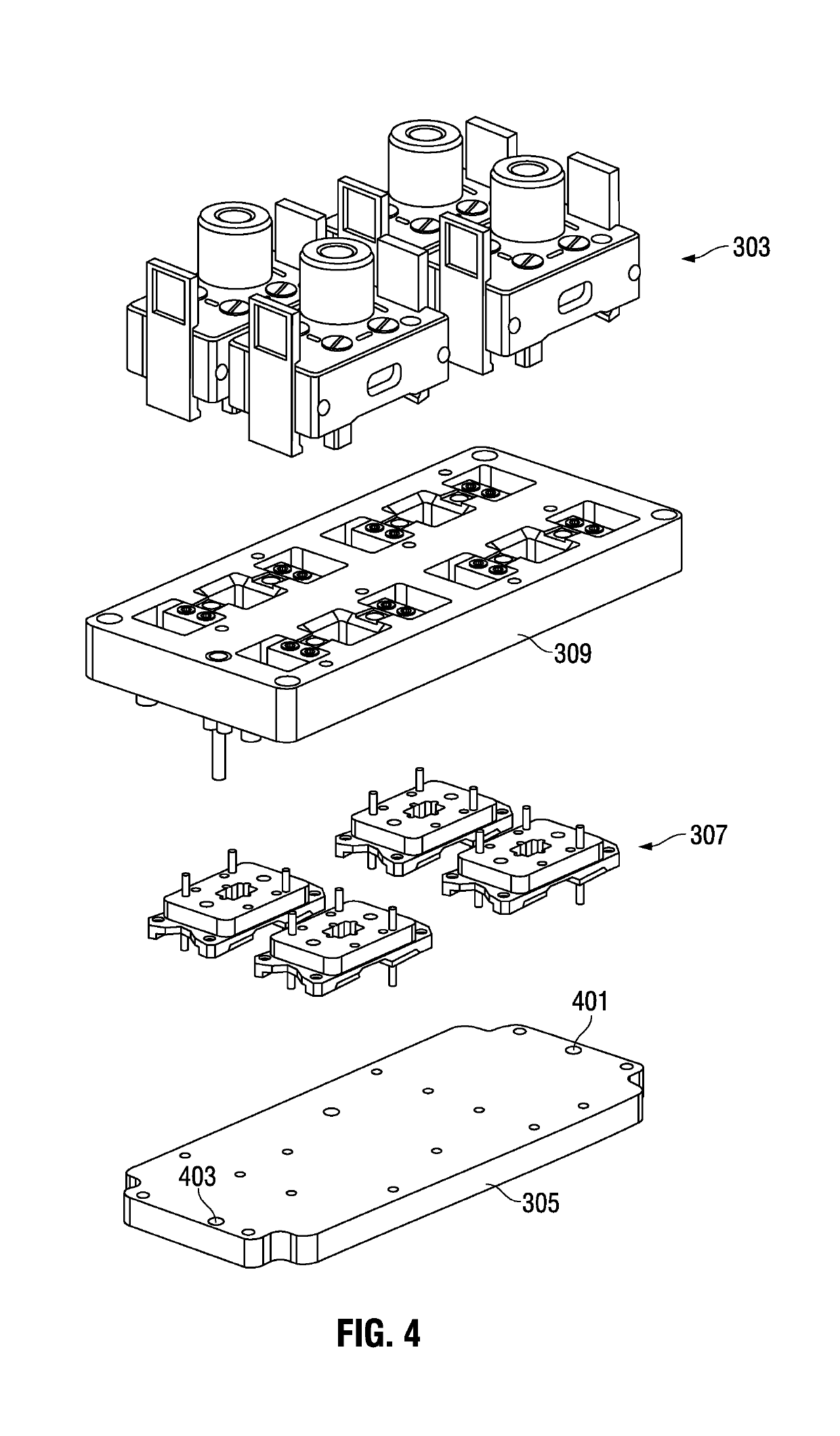

[0004]In one embodiment, an integrated circuit (IC) test fixture includes a plurality of sockets. An alignment plate is coupled to the sockets and configured to provide alignment between an IC handler and the IC test fixture. One or more manual test lids is removably coupled to the alignment plate, the one or more manual test lids coupled to the alignment plate for manual testing one or more integrated circuits, the manual test lids removed from the alignment plate for use of the IC test fixture with the test handler.

[0005]In another embodiment an integrated circuit (IC) test fixture includes a device interface board and a plurality of daughter card subassemblies for receiving integrated circuits for testing, the plurality of daughter card subassemblies coupled to the device interface board. Each daughter card subassembly includes a daughter card, a plurality of sockets coupled to the daughter card, and an alignment plate to provide alignment between an IC handler and respective ones o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap