Work support system

a multi-functional, work platform technology, applied in metal-working machine components, metal-working apparatus, manufacturing tools, etc., can solve problems such as inefficiency, damage to work surfaces, objects, etc., and achieve the effect of improving work efficiency, reducing work difficulty, and reducing work spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

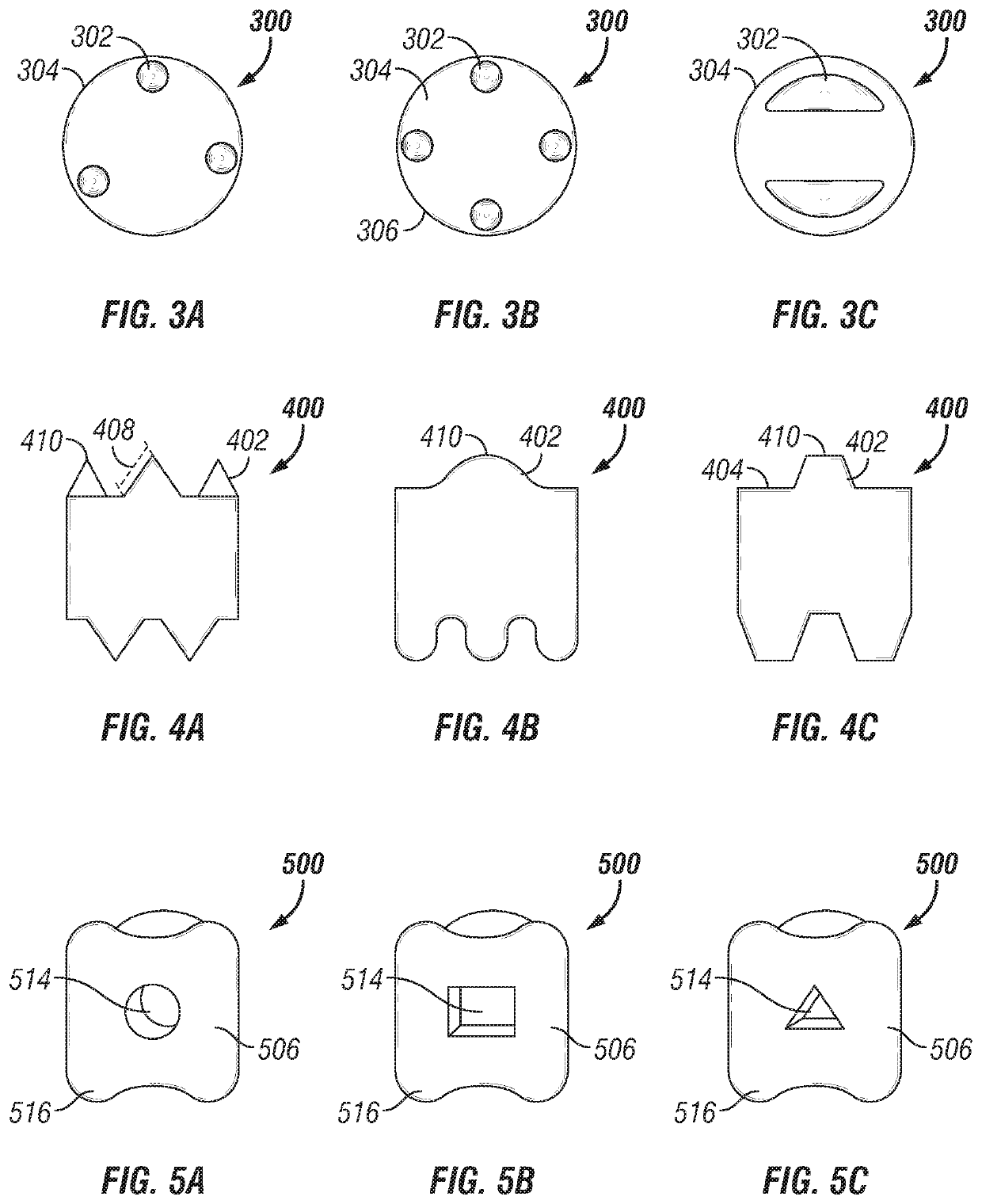

[0038]As shown in FIGS. 3A-3C, embodiments of a work stand 300 may include various configurations of supports 302 on a support surface 304 thereof. Such supports 302 may have a generally circular cross section (FIGS. 3A-3B), a semi-circular cross section (FIG. 3C) or various other cross-sectional configurations such as a triangular / wedge configuration, etc.

[0039]In various embodiments, supports 302 may vary in width and cross-section as they extend away from the support surface 304. In various embodiments, the supports 302 may also be configured to mate with similar or dissimilar supports on a second work stand 300, such that a plurality of such work stands 300 may be securely stacked to achieve a desired height.

[0040]In various embodiments, supports 302 are generally spaced substantially equidistantly upon the support surface 304 to provide for an improved balance to a supported object. In one embodiment, the supports 302 will typically be disposed along or near a periphery of the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap