Safety switch with unlatching disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

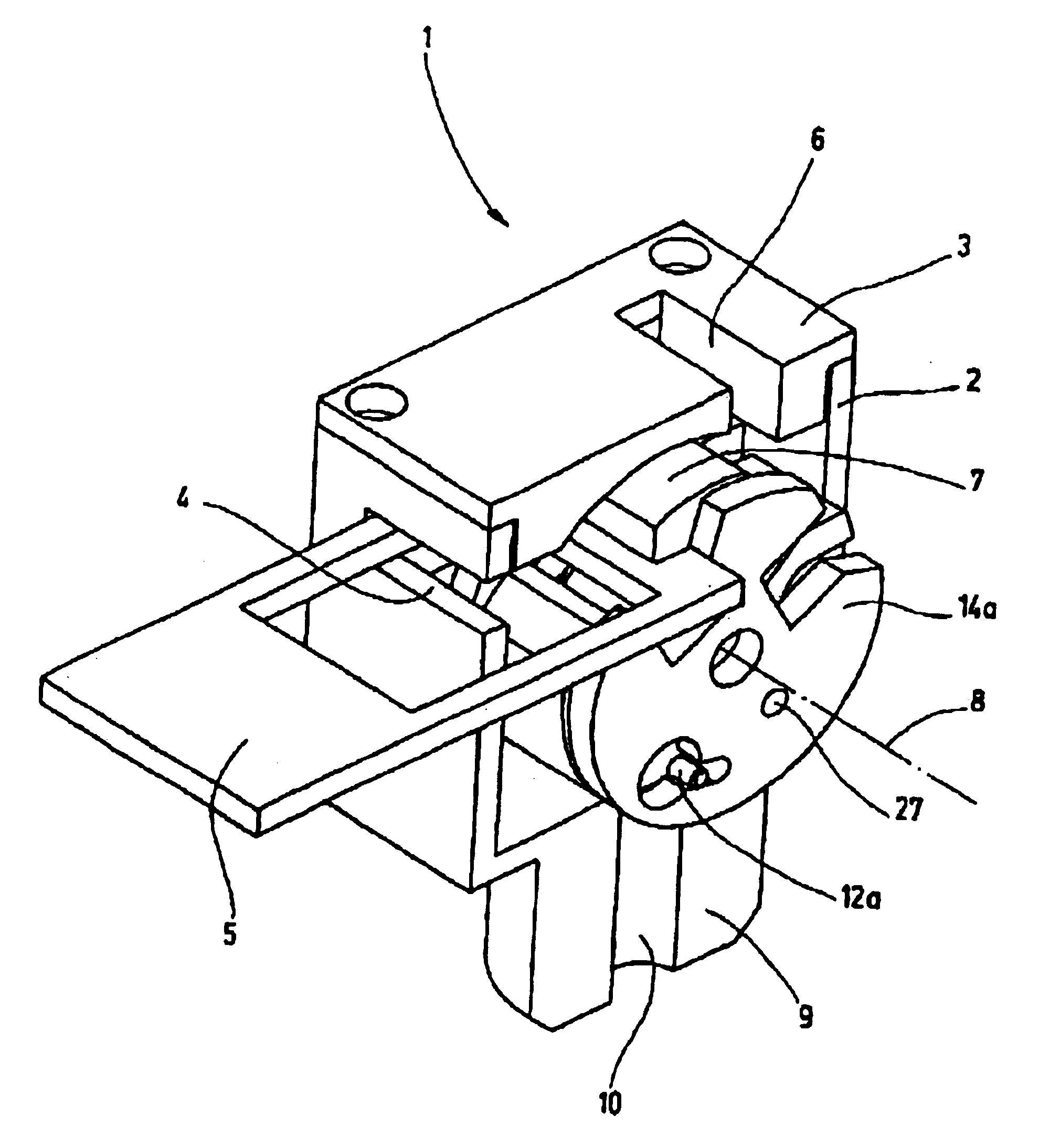

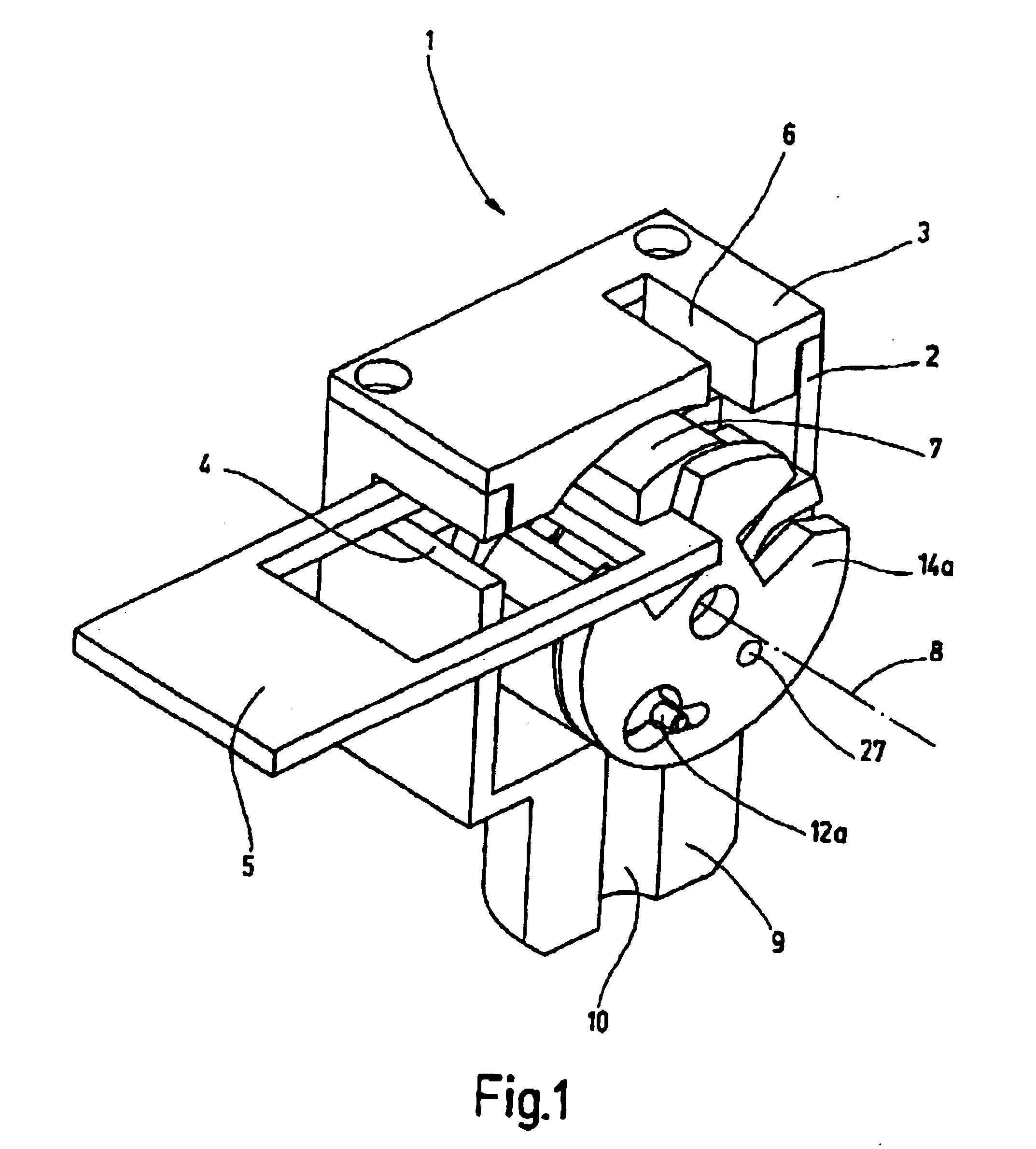

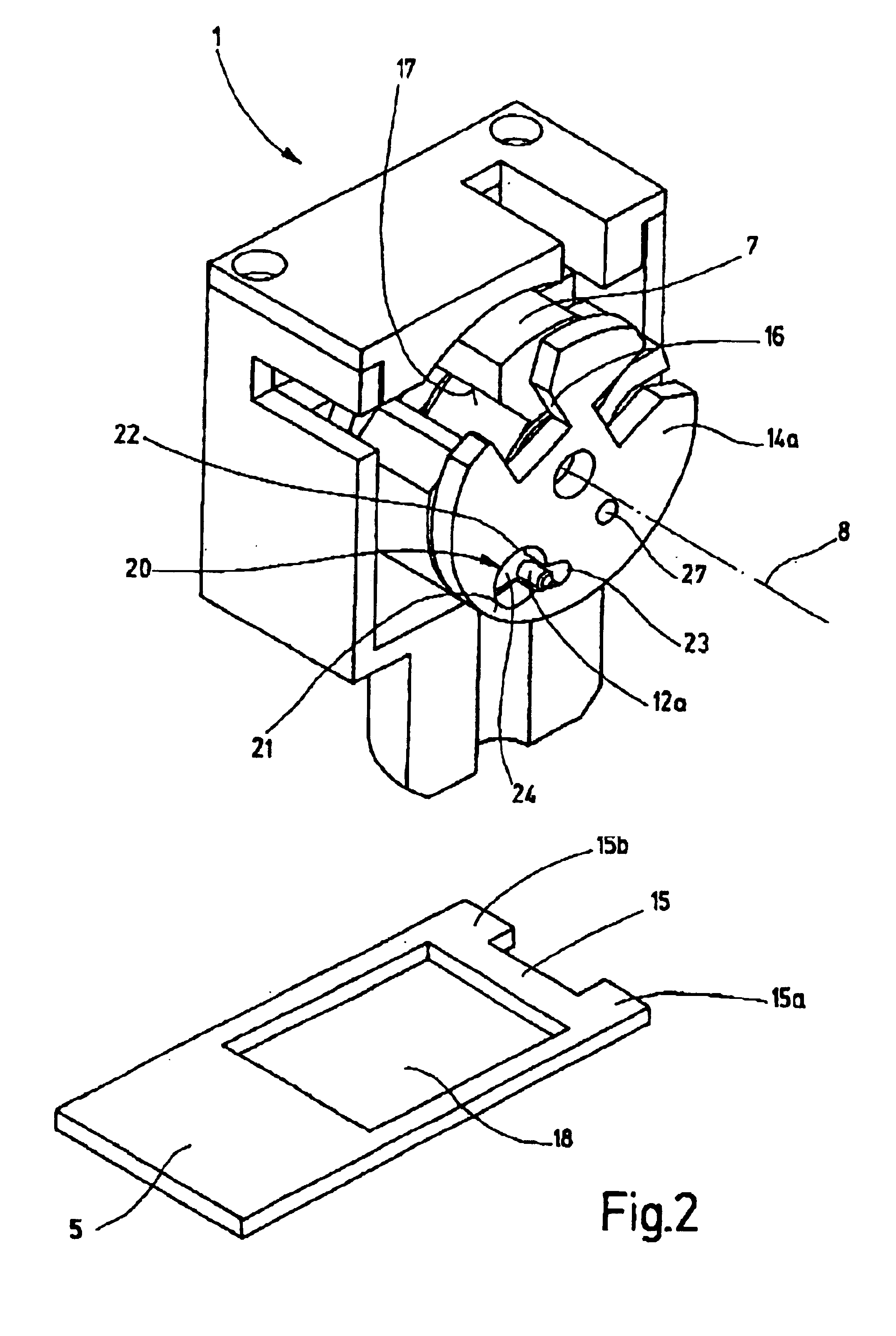

FIG. 1 illustrates a safety switch 1 according to an embodiment of the present invention, with a housing having a housing top part 2 and a housing cover 3. Cover 3 may be slip-on mounted on the housing top part 2 and fastened to it, for example, by screws. The housing top part 2 has a first insertion slot 4 for the actuator 5. The housing cover 3 has a second insertion slot 6 for the actuator 5. The directions of insertion predetermined by the two insertion slots 4 and 6 enclose or are spaced by an angle of more or less 90°.

A switching disk 7 is mounted in the housing top part 2 for rotation about an axis 8. When the actuator 5 is inserted into at least one of the two insertion slots 4, 6 the switching disk 7 illustrated in FIG. 1 is rotated clockwise causing a switching rod 28 (not shown in FIG. 1) to be displaced axially so that an electric connection is made. The guide of the switching rod 28 and the electric contact elements are mounted in a switch housing component (not shown in F

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap