Cable connector assembly having pull tab

a connector and pull tab technology, applied in the direction of electrical equipment, connection, coupling device connection, etc., can solve the problems of conductors standing a good chance of being divorced from contact modules, affecting signal transmission, and only loosening screw connections by operators, etc., to achieve convenient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Reference will now be made in detail to the preferred embodiment of the present invention.

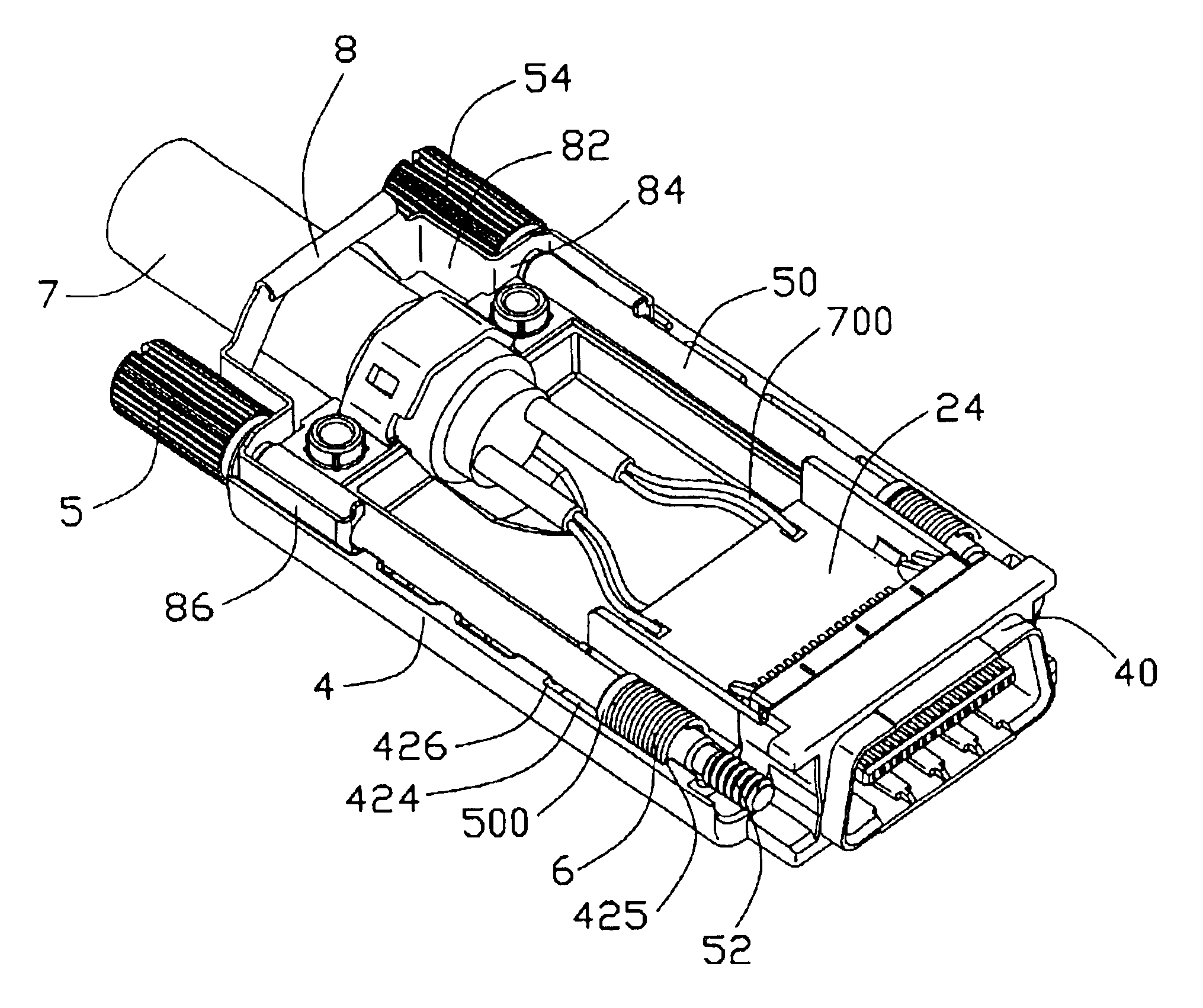

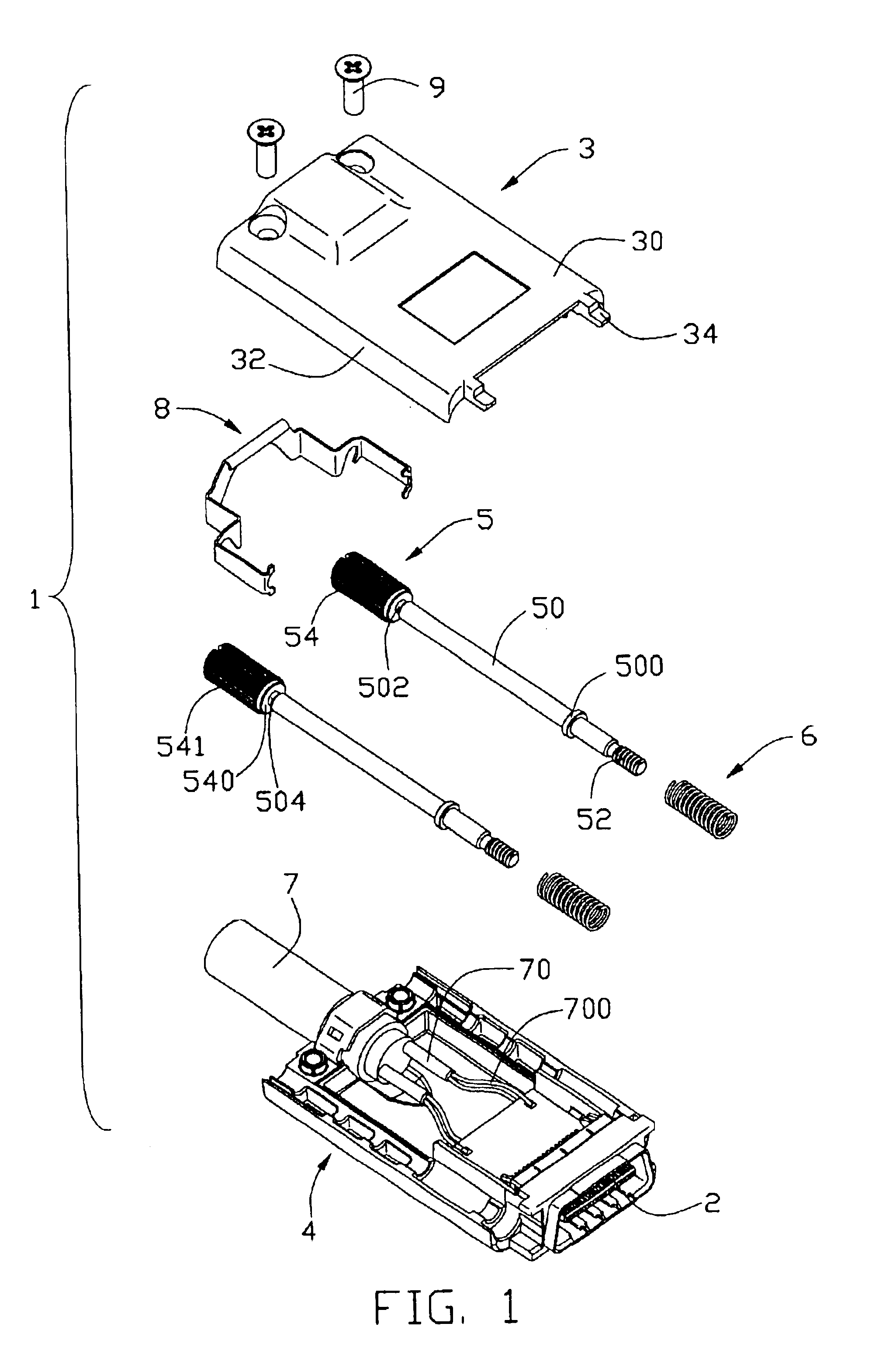

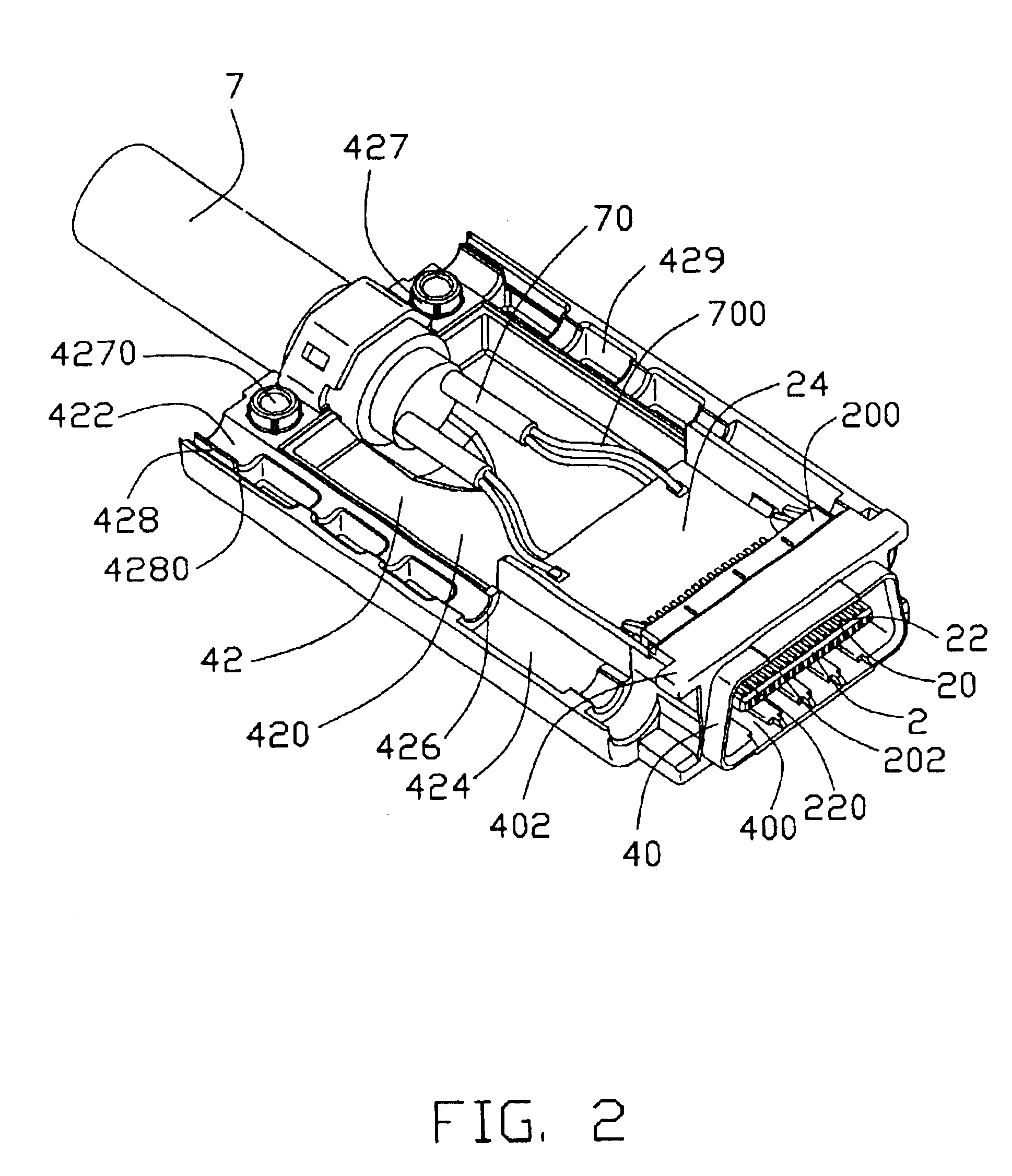

Referring to FIG. 1, a cable connector assembly 1 in accordance with the present invention comprises a contact module 2, an upper die cast cover-half 3, a lower die cast cover-half 4, a pair of fastening members 5, a pair of spring members 6, an electrical cable 7, a pull tab 8 and a pair of screws 9.

Referring to FIGS. 1-3, the contact module 2 comprises an insulative housing 20, a plurality of contacts 22 and a printed circuit board 24. The insulative housing 20 comprises a base portion 200, a tongue portion 202 extending forwardly from the base portion 200 and a plurality of passageways (not labeled) extending from the tongue portion 202 through the base portion 200.

The contacts 22 are received in the passageways of the insulative housing 20. Each contact 22 comprises a contacting portion 220 retained in the tongue portion 202 for contacting with a complementary connector (not shown) and a conne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap