Air hypocaust structure for cooling and/or heating

a technology of air hypocaust and structure, which is applied in the direction of air heaters, lighting and heating apparatus, heating types, etc., can solve the problems of reducing the heat transfer efficiency of the hypocaust system, leaking, and easy blockage or corrosion, and a lot of labor and repair costs are needed to repair the broken pip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]Reference will now be made in detail to the present preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout.

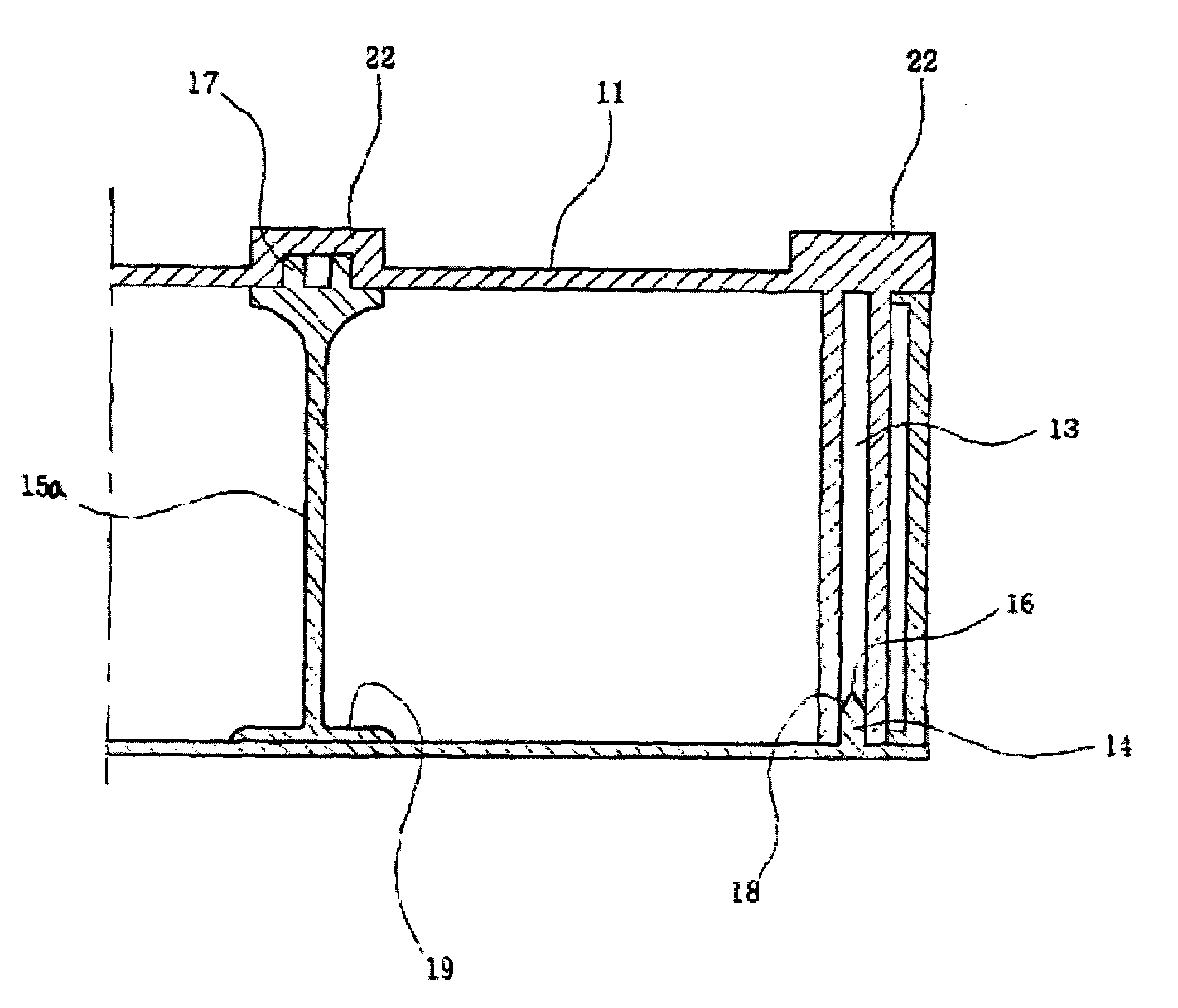

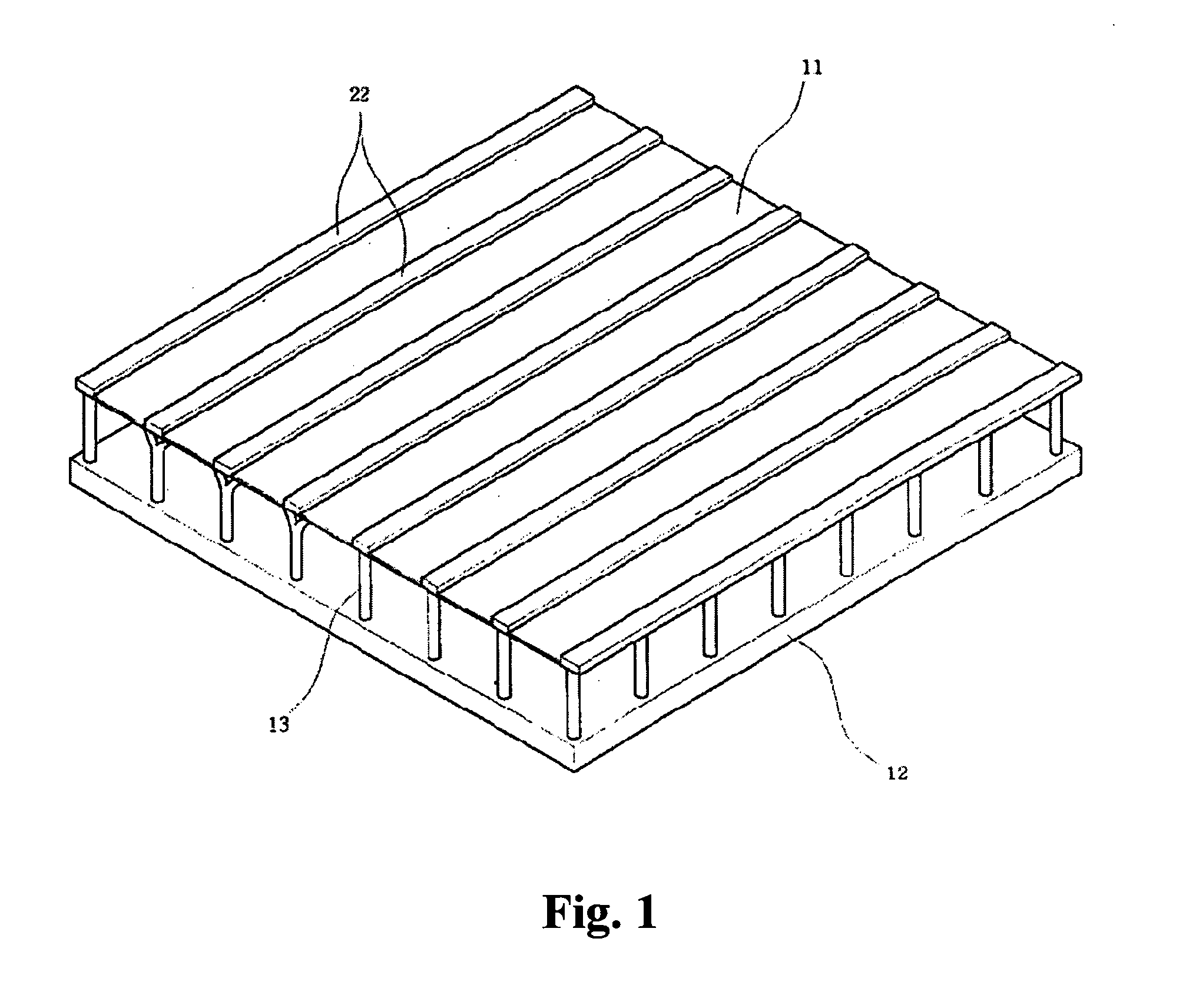

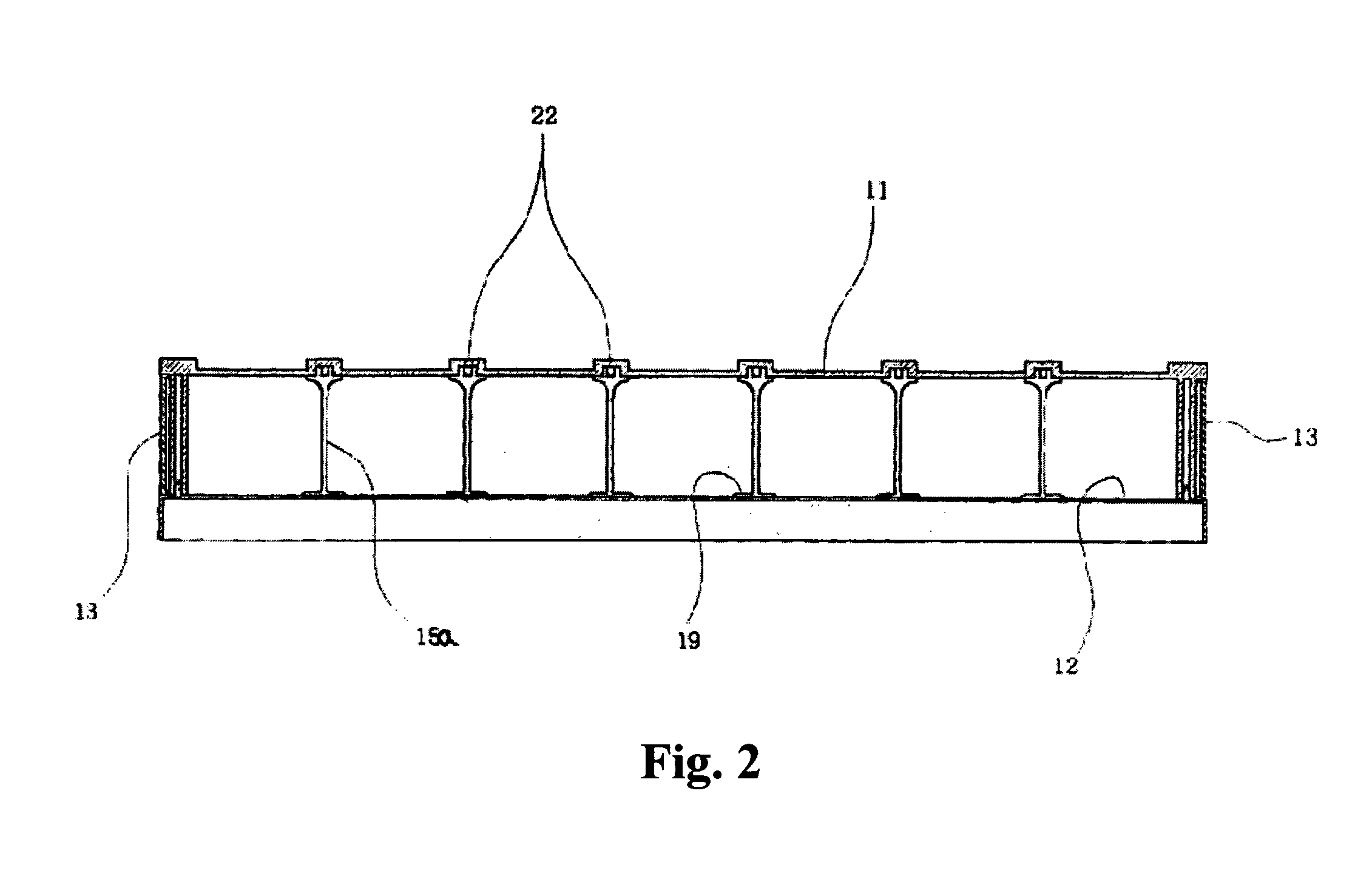

[0018]As shown in FIGS. 1 and 2, the present invention is characterized in that an air hypocaust structure includes an upper plate 11 having a plurality of recess parts 17 positioned at regular intervals, and integrally provided with a plurality of support legs 13 positioned along an edge thereof at regular intervals, a base plate 12 provided with a plurality of projections 14 corresponding in position to the support legs 13, and a plurality of curved and straight guide plates 15a and 15b selectively installed between the upper plate 11 and the base plate 12, thereby controlling a flow direction of a cold or a hot air current.

[0019]By the use of the air hypocaust structure according to the present invention, a dwelling is cooled or heated by a conduction

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap